Coca-Cola: is “opening happiness” sustainable?

Has Coca-Cola taken measurable steps toward becoming a more sustainable business, or have they simply greenwashed their real environmental impact?

Is “opening happiness” sustainable?

Coca-Cola (NYSE: KO) is the largest beverage company in the world, with a market capitalization nearing $200bn (as of 12/31/2015), a corresponding net income of $7.4bn, and unparalleled brand awareness. The company has approximately 500 brands to its name, a distribution network that spans over 200 countries, and an aggregate 3800+ products globally. With such global scale, we would be remiss not to ask what they are doing to mitigate their global environmental footprint. [1]

Ingredients for impact? [2]

Though water is a key ingredient for Coca-Cola’s product portfolio, it is also a finite resource that is increasingly in demand. Climate change exacerbates the issue by impacting both quality and quantity of water available for human consumption. [3] With that in mind, Coca-Cola aims not only to optimize its use of water, but also to protect freshwater resources and watersheds globally.

Given the high proportion of non-biodegradable materials used in Coca-Cola’s packaging (e.g. aluminum, plastic), the company is especially focused on supporting recycling initiatives and incorporating renewable materials into its production process, e.g. the PlantBottle, shown below.

To reduce negative environmental externalities associated with “manufacturing processes, packaging formats, delivery fleet, refrigeration equipment and ingredient sourcing,” the company is committed to improving its energy efficiency across while leveraging partnerships across non-profit, corporate, and government agencies.

In addition to water, Coca-Cola products involve numerous agricultural ingredients (e.g. sugar, coffee, tea, fruit and corn). It is important that these products be produced in a sustainable way that mitigates impact on the environment. To do so, Coca-Cola has partnered with the World Wildlife Fund and Cargill “to help local farmers increase corn yields, reduce post-harvest waste and reduce their environmental footprints.”

Goals & Progress? [2] [4]

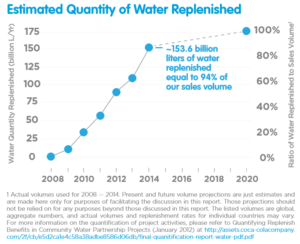

Goal: “By 2020: safely return to communities and nature an amount of water equivalent to what KO uses in finished beverages and production.” Progress: “Ahead of target.” From 2005 – 2014: KO balanced approximately 94% of the equivalent amount of water used in finished beverages, i.e. ~154bn liters of water replenished.

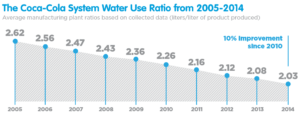

Goal: “By 2020, improve water efficiency in manufacturing operations by 25% vs. 2010.” Progress: “On track.” Manufacturing water efficiency has improved for twelve consecutive years.

Goal: “Work with partners to recover and recycle equivalent of 75% of bottles and cans introduced by KO into developed markets by 2020.” Progress: “On track.” The company estimates a recovery rate of 61% in developed economies.

Goal: “Recover and recycle 50% of the equivalent bottles and cans introduced globally.” Progress: “On track.” Approximately 48% equivalent of KO bottles and cans are recovered and subsequently recycled.

Goal: “Source 25% of PET plastic from recycled or renewable material by 2015.” Progress: “Off track.” Only 12.4% of packaging materials globally are made with renewable or recycled material. ![]()

Goal: “Reduce carbon footprint of the ‘drink in your hand’ by 25% by 2020.” Progress: Tentative reduction targets established through 2020. ![]()

Goal: “By 2015: all new cold-drink equipment will be HFC-free globally.” Progress: “Off track.” 2014: Only ~30% of new equipment purchases were HFC-free. ![]()

Goal: “Grow business—but not carbon emissions from manufacturing—through 2015.” Progress: “Off track.” 2014: total emissions were 16% above 2004 figures. ![]()

Goal: “By 2015, reduce emissions from manufacturing in developed countries by 5% vs. 2004.” Progress: “Achieved.” 2014: emissions 13% lower versus 2004.

Goal: “By 2020, sustainably source key agricultural ingredients.” Progress: “On track.” Key ingredients to be sourced in accordance with Sustainable Agriculture Guiding Principles. ![]()

In conclusion…

Coca-Cola’s effort to mitigate its environmental impact is admirable. That said, many of the goals stated by the company are not only subjective, but also set for completion by 2020, calling into question the veracity of initiatives deemed to be “on track.” Even still, many of their initiatives appear to be “off track” despite that they themselves set for the goals and corresponding timelines.

What more can Coca-Cola do?

Plant bottles are still plastic. Despite a more environmentally friendly production process, using ethanol from renewable sources (i.e. sugar cane), the output remains basically unchanged: a non-biodegradable plastic bottle. And unfortunately, consumers only recycle a small fraction of those bottles that they use.

Recyclable does not mean recycled. In addition to company-led measures to offset environmental impact, Coca-Cola would be wise to amplify its efforts by educating its consumers on the importance of their participation in this same process.

Corporate and consumer collaboration is not enough. [5] Coca-Cola has been proactive about establishing partnerships in order to move their environmental initiatives forward. They should pursue a similar strategy with to partner with state and foreign governments in support of bottle bills, “state legislation that creates a deposit system for beverage containers. In the 10 states where they’re enacted, bottle recycling rates range from 60 percent to 80 percent, dramatically higher than the national average.”

(796 words.)

Sources:

[1] http://www.coca-colacompany.com/our-company/infographic-coca-cola-at-a-glance

[3] https://www3.epa.gov/watersense/docs/ws_qanda508.pdf

[5] http://www.slate.com/articles/health_and_science/green_room/2011/06/plastic_by_any_other_name.html

Photo credits:

http://www.coroflot.com/jessica_tan/ecoca-cola?city=Singapore&specialty=3&

http://allinallnews.com/wp-content/uploads/2014/06/green-coke.png

I found KO’s commitments on packaging fairly uninspiring. As you point out, there is an important distinction between what is recyclable and actually gets recycled. Moreover, I wonder what kind of responsibility KO has, as a company that generates so much plastic waste, to be leaders in R&D on biodegradable bottles. Imagine a world where Coke actually made a commitment to be an industry leader and generate a biodegradable plastic bottle that could be produced cost-effectively. Now that would be a real commitment to sustainability. The science is already being developed (http://inhabitat.com/biodegradable-algae-water-bottles-that-provide-a-green-alternative-to-plastic/) so if the commitment were real Coke could do it.

It’s really interesting to read the comparison between goals committed by Coca-Cola and the actual progress that has been made. I think the points made on packaging is particularly true – “reusable material” does not necessarily mean it has been recycled. How can Coca-Cola do a better job to cultivate the behavior of recycling and in the meantime make it easier for the public to do so? However, in terms of “Energy and Climate”, it is clear that the problem lies within the organization. Not enough efforts are made to reduce the carbon footprint in capital expenditure investment and manufacturing process. Coca-Cola should align the priority internally and deliver the promise consistently in performance metrics. Otherwise, it could be well like the author pointed out in the beginning – it’s an act of “green-wash” rather than real and sustainable impact.