Clover Food Labs: Using Technology to Bring The “Real Food” Movement to Cambridge, MA.

Customer demand for healthier, more local fast food options has skyrocketed in the past few decades. Yet, major restaurant chains have been hesitant to enter the space, due to obstacles of inconsistent food supply, dependence on local seasonality, and short shelf-life of fruits and vegetables. Enter Clover Food Lab – a chain of vegetarian fast food trucks and restaurants in Boston – that has overcome the traditional obstacles to delivering a local, fresh, and fast food experience by integrating technology advancements into its operating model.

“We rely a lot on technology… It’s no exaggeration that I literally could not make the food we’re making ten years ago… (It drives) our ability to move as quickly as we do and source the way we do.” – Ayr Muir, Founder and CEO of Clover Food Lab[1]

Customer demand for healthier, fast options has skyrocketed in the past two decades. So, why have many restaurant chains hesitated to move toward healthier menu options? Research has shown that executives most frequently cited the following obstacles: Spoilage and short shelf life of fruit and vegetables, inconsistent supply, and additional storage requirements. [2]

These are particularly challenging barriers to overcome in the low-margin business of fast food. Yet, Clover Food Lab has harnessed digital innovation to create an operating model that overcomes these barriers to deliver locally-sourced, vegetarian fast food. Clover’s commitment to customers centers around fresh food, a seasonal menu that changes daily, local sourcing, and an efficient experience. [3] In fact, the company uses no processed, prepared, or frozen products, with the exception of ketchup and mayonnaise.[4] This is radically different than other players in the fast casual markets, even Chipotle and Panera.[5]

Building a Digitally-Connected Operating Model:

Founded in 2008 by HBS graduate, Ayr Muir, Clover now encompasses 11 restaurants and food trucks and 300 employees.[6] What has enabled Clover to thrive in the local fast food space is its use of technology:

- Real-time Menu: Every Clover brick-and-mortar uses high-definition flat-screen monitors to display real-time versions of its menus, which are connected to managers’ iPad devices, via a cloud-based operating system. This enables changes to the menu at any given time.[7] The menu is then connected to Clover’s inventory management system. Once an ingredient runs out, the products dependent on that ingredient are automatically removed from the menu and the ordering interface.[8] This allows Clover to seamlessly adapt to the challenge of inconsistent supply.

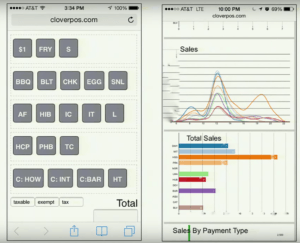

- Customization of Mobile Ordering System: Historically, running a fast food operation required investing $60,000+ in inflexible point-of-sale (POS) register systems. Because of Clover’s need for a system that could adapt with its frequently changing menu, Muir with a local developer on a mobile app that could accommodate daily menu changes. This customized POS system works on both iPhones and Androids, enabling flexibility across employees. Because the ability to serve customers is not limited by fixed infrastructure (e.g., cash registers), Clover can flex its ordering staff in accordance with customer demand fluctuations, delivering on its promise of efficient service.

- Delivering Food Fast: Clover employees are “obsessed with speed and constantly time themselves”, with an average service time of around 3.5 minutes.[9] The company heavily relies on connected devices to achieve this quick speed: Once a customer orders, the order gets sent to the kitchen via Wufoo – a form-building app.[10] From there, food preparers reviews orders via an iPad. Because Clover can track the throughput time of each menu item, it is able to provide a real-time update to customers. Additionally, managers can track the cycle times of steps in the process, identifying bottlenecks and adapting operations.[11]

Display Screens at Clover – Harvard Square (11/2016)

- Tight Feedback Loops: Clover crowdsources product feedback and new recipe ideas via its blog, active management of its social media handles, and monthly customer surveys.[12] Clover also uses its custom POS system to track customer behavior – the system explicitly prompts the order-taker to ask if you’ve tried a product before. If not, he or she will record this information, and the data will be used to analyze the success of new items, based on the frequency of return purchases.[13] The POS system also allows employees to monitor how sales of new items are performing against projections at each location, as well as sales mix by item, category, day, and time.[14]

While Clover has utilized technology to deliver an ever-changing menu and an efficient experience to customers, there are several opportunities to further enhance operations:

- Safety Sensors: In 2013, Clover closed after being linked to a Salmonella outbreak. In response, Clover underwent a health inspection, which found that Clover was keeping multiple ingredients at temperatures that were above the “safe level” for preventing bacteria growth.[15] To prevent this from happening in the future, Clover could invest in sensor technology that is able to monitor the condition and temperature of ingredients upon arrival and during storage.[16] These sensors can be linked to the cloud and coded to alert key stakeholders of any issues that might compromise food safety.[17]

- Remote Asset Monitoring: To maintain its commitment to affordable prices, Clover will need to maximize use and lifetime of its equipment. By using remote equipment sensors, managers could monitor everything from kitchen ovens to HVAC systems to lighting to quickly flag any abnormalities that might lead to inefficiency. Other restaurant chains that have implemented monitoring of fixed assets have seen an increase in labor productivity and lower costs.[18]

800 words.

[1] The Real Food Movement Panel. Perf. Ayr Muir. The Edge Conference. The Ad Club, 12 Jan. 2015. Web. 17 Nov. 2016.

[2] Glanz, Karen et al. “How Major Restaurant Chains Plan Their Menus: The Role of Profit, Demand, and Health.” Science Direct. American Journal of Preventative Medicine, May 2007. Web. Nov. 17.

[3] “It’s Almost a Freezer.” Clover Food Lab. Clover Food Lab, 20 Nov. 2013. Web. 15 Nov. 2016.

[4] “Food.” Clover Food Lab. Clover Food Lab. Web. 15 Nov. 2016.

[5] Ibid.

[6] “Focus on Founders: Ayr Muir and Clover Food Lab.” McKinsey Alumni Center. McKinsey, 7 Oct. 2014. Web. 15 Nov. 2016.

[7] Guerra, Cristela et al. “10 Things We Learned in 24 Hours at Clover HFI.” Boston Globe. Boston Globe, 27 April 2015. Web. 15 Nov. 2016.

[8] St.John, Olivier. “Healthy food served in less than 4 minutes.” USA Today. USA Today, 2 April 2013. Web. 15 Nov. 2016.

[9] Ibid.

[10] Ibid.

[11] “mPOS Brings Clover A Little Luck.” What’s Next Media and Data Analysis, LLC. PYMNTS.com, 5 May 2016. Web. 15 Nov. 2016.

[12] William Eggers and Paul Macmillion. “A Billion to One: The crowd gets personal.” Deloitte University Press. Deloitte Consulting, 26 January 2015. Web. 15 Nov. 2016.

[13] “In-Testing Beaker.” Clover Food Lab, Clover Food Lab. 28 October 2016. Web. 15 Nov. 2016

[14] “Clover Sales Mix.” Clover Food Lab, Clover Food Lab. 12 October 2016. Web. 15 Nov. 2016

[15] “Clover Inspection Report.” 2013: City of Boston. Department of Inspection Services, 12 July 2013. Web. 15 Nov. 2016.

[16] “How the Internet of Things will Impact Food.” Food Safety News. Food Safety News, June 2015. Web. 15 Nov. 2016.

[17] Flusberg, Martin. “Internet of Things to Revolutionize Operation of Restaurants and C-Stores.” Powerhouse Dynamics. Powerhouse Dynamics, 2015. Web. 18 Nov. 2016.

[18] Ibid.

[19] “Clover Food Lab – Boston (Cambridge).” Gastronomy Blog. Gastronomy Blog, 01 October 2010. Web. 18 Nov. 2016.

Great article – thank you Ryan! I love how Clover are so heavily focused on minimising the time from when the customer orders to when the customer receives the food order. However, I often see a huge queue at the Harvard Square Clover and to date this has put me off going inside. I believe to lower the queue wait time, Clover could further digitise their processes in three ways: invest in instantaneous contactless payment systems such as Applepay, develop an app to allow customers to make ordering decisions prior to arrival in a clover store and expand their app offering to allow customers to order in advance and pick up in-store. Through these three digital mechanisms I believe Clover could both lower the time required to serve a given customers, lower the queues in store, improve existing customer satisfaction and generate new customer numbers.

Thanks for a great post Ryan! As a Clover fan, I didn’t realize the extent to which they are more like a tech company rather than a food company, and that their high-tech model is precisely what makes their business successful and sustainable (definitely from an environmental standpoint, and presumably from a business standpoint as well). Do you have any thoughts on how Clover can change the expectations consumers have around fast food restaurants in general, which is product consistency (e.g. a big mac sold in NYC should also be sold in Boston)? I definitely think Clover could play a huge role in customer education and emphasizing the importance of local, environmentally friendly sourcing practices and their implications on food availability (which I realize they do some of, but making a more concerted effort with similar companies and even partnering with other fast food chains to change the industry mindset).

Great post showing how technology can help bringing back quality in our fast food restaurants!

I particularly like the seasonality aspect of the food offering: this could be a first step to creating a more sustainable food industry, where consumers accept the idea that they cannot have all types of food all year round.

I would be curious to learn more about how the company managed to make its operations flexible enough to accommodate a menu that is in constant development, as they state on their website. Usually fast foods rely heavily on standardization in order to cut costs: for instance, the steps to create a Big Mac are codified in a scientific manner, and are applied exactly in the same way across the entire world. In the case of Clover, however, the use of seasonal ingredients might introduce substantial complexity in its operations, requiring specific and frequent training. This tension between seasonality and local sourcing on one hand, and standardization on the other hand, will become even more critical as the company expands beyond its current 11 restaurants.

That said, I love the model and I really hope that their approach will set a new gold standard in the industry!

[1] https://www.cloverfoodlab.com/food/

I’ve been meaning to try Clover for some time now, and this just further reinforces why I need to! I knew tat 1he food was supposed to be quite good, but had no idea the company was so innovative beyond its food. There are a lot of restaurants that have frequently changing menus and rely on chalkboards or tape and markers to make these adjustments. I can only imagine how much of a pain operating POS systems for those restaurants can be.

At 11 restaurants, the Clover operation is much larger than I expected. That being said, with the stress placed on locally sourced ingredients, it may be difficult to continue to expand. Chipotle and many other restaurants are using locally sourced ingredients where possible, but they don’t have as strict sourcing regulations as Clover.

Who wants to go for dinner, tomorrow?!

I love the concept of updating the menu and systems based on the inventory. I do wonder how they are able to make all of this fresh food so quickly! I think the company culture of speed is enabled with the direct feedback and tracking of their process. I do agree with CC on the perception of the long line that has deterred me in the past. I recently went into Clover near MIT and the employees were really energetic and excited about helping you make your order (and also asking if you had had something before, now I know why!). I was concerned about the speed since I was heading to a meeting and they made a sandwich incredibly quickly right in front of me! So I think that once someone has tried Clover once, they won’t necessarily be deterred by the line. The question is, how can they get more customers over that first visit hurdle?

I agree the safety sensors would be a huge value-add for Clover, and many quick service restaurants as they have faced a few outbreaks that have greatly impacted their business.