Building Towards a Cleaner Future: Lafarge Cement & Concrete

Can one of the worlds largest polluters have a net positive impact on climate change?

“The challenge presented by climate change is transforming our business” –Bruno Lafont, Chairman and Chief Executive Officer 2014 [1]

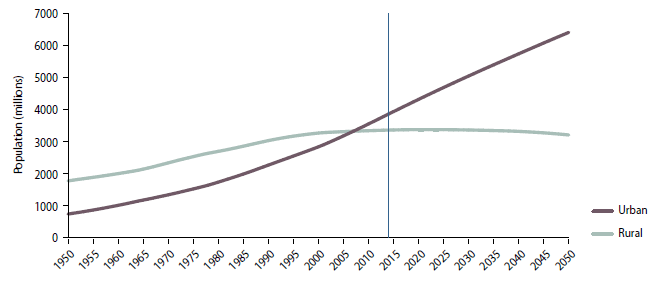

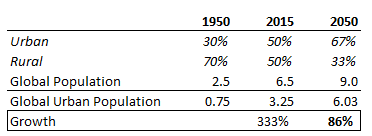

In 2050, the percentage of the global urban dwellers will grow from 50% to 66% [2], while the overall population is anticipated to grow by 6.5 to 9.0 billion [3]. This means an additional ~3 billion people are going to be living in urban cities. How many additional homes, offices, roads, bridges, and airports are going to be required to accommodate these new urban dwellers?

Urban and Rural Population of the World 1950-2050

Lafarge is a global leader in the building materials industry providing cement, concrete, and aggregates for use in the construction of buildings and infrastructure. Together with its parent company, it has 2,500 production plants located across 90 countries, 100,000 employees and $30 billion in revenues annually. The company will inevitably be a major supplier of the raw building materials needed to serve the additional 3 billion urban dwellers on our planet through 2050.

Lafarge is a massive greenhouse gas emitter, reporting over 100 million tons in 2014. This is a result of the sheer scale of the company’s operations, combined with the energy intensive nature of concrete production and transportation, and the fact that carbon dioxide is a direct byproduct of concrete production.

Climate change presents several direct threats to the company’s business model. The looming possibility that international governments will impose a price on carbon would provide a shock to the price of energy, which is a major input cost to the production and transportation of cement products. Further, depending on the structure of the imposed carbon regulation, there is a possibility that Lafarge will be taxed on its plant level direct carbon emissions from the production of cement. Finally, the cement production process requires water as an input, and a significant number of regions in which Lafarge operates are already experiencing water shortages presumed to be a direct effect of climate change.

These same threats provide several opportunities for Lafarge to adapt its business model enabling it to grow its top line revenue and help mitigate greenhouse gas emissions globally. Buildings account for 35-40% of total energy use globally, with 90% of this usage coming from heating, cooling and lighting, and only 10% from the energy inputs related to the materials and construction process [4]. By designing smarter, more energy efficient building materials with better insulation, Lafarge believes that it can reduce buildings’ heating and cooling energy usage by 60-80% with existing material technologies, which can more than offset the carbon emissions associated with the production of the materials themselves [5]. The benefits of energy efficient building materials will become more pronounced over time as temperatures become more extreme because of climate change and energy prices increase.

Final Energy Consumption by sector and buildings energy mix, 2010 [4]

In anticipation of a world where carbon emissions have an economic cost, and in response to changing demands for more efficient building materials, Lafarge has developed a voluntary emission reduction strategy focusing on:

1.) improving kiln energy efficiency,

2.) producing less carbon intensive blended cements,

3.) procuring energy from renewable energy projects and co-generation projects which recycle the heat produced from the byproduct of traditional power generation projects to create additional electricity [5].

Also, it has strategically located its projects near railways and ports to minimize energy used during the transportation of its concrete. Finally, because of the regional scarcity of water, Lafarge has developed robust water recycling techniques reducing its overall usage, freeing up resources for local and individual consumption.

Lafarge has voluntarily committed to reduce CO2 emissions per ton of cement by 33% by 2020, and as of 2014, had already achieved a 26.4% reduction compared to 1990 levels [5]. I admire Lafarge’s recognition of its contribution to climate change, and developing and successfully implementing a strategy to reduce its impact far beyond any imposed government regulations. However, I believe that Lafarge should go one step further, and assume the responsibility of lobbying policy makers to develop and enforce stricter standards on the industry as whole. Lafarge and its parent company are a powerhouse in the global construction materials sector, with the capability and influence to decision makers at the highest levels. Successfully imposing stricter standards on the industry would not only create a competitive advantage for Lafarge it will enable the company to have far greater global impact beyond anything it could do though its internal operations. It is critical that the homes, offices, roads, and airports required to support the additional 3 billion urban dwellers over the next 35 years are built with materials produced in a smart, efficient, and responsible way.

(777 Words)

[1] Lafarge, Sustainability Report 2014, Page 3, Retrieved from: http://www.lafarge.com/sites/default/files/atoms/files/04222015-publication_sustainable_development-climate_change_and_energy-uk.pdf

[2] United Nations Department of Economic and Social Affairs, World Urbanization Prospects 2014, Page 7

[3] Population Reference Bureau, Human Population: Population Growth, Retrieved from http://www.prb.org/Publications/Lesson-Plans/HumanPopulation/PopulationGrowth.aspx

[4] International Energy Agency, Transition to Sustainable Buildings: Strategies and Opportunities to 2050

[5] Lafarge, Climate Change and Energy Brochure, Retrieved from: http://www.lafarge.com/sites/default/files/atoms/files/04222015-publication_sustainable_development-climate_change_and_energy-uk.pdf

Such an interesting article! I really like your idea that Lafarge should drive greater policy and regulatory changes in the industry. But I wonder whether their voice should be limited just to the cement industry, or expand further into the real estate? I believe they would have more room to fundamental impact in terms of sustainability as well as create monetary value for their business if they did this. For example, they could lobby regulators to pass regulations that required all new buildings to use the insulated cement – for which Lafarge could charge a premium.

Interesting post, particularly as a complement to Amir’s post about architectural firms. It sounds like Lafarge has been proactive about addressing climate change through these voluntary measures. Also impressive is that they can reduce energy usage by such a significant amount, 60-80%, using technologies. However, the move to locate projects near railways and ports seems like a short-term solution and limiting for their business. I’m curious to know whether this is a strict commitment for the future or if they are doing it when convenient, more as a “nice to have” — if it’s the former, this could be a powerful signal to the rest of the industry. I also agree with Shivika’s point above that there are opportunities for Lafarge beyond the cement industry and to partner with developers or even architectural design firms. It seems that the whole ecosystem of building would benefit from moving more closely in lockstep.

Fascinating post! Cement is an essential input to many applications across public and private sectors. Perhaps the company could also optimize its distribution network (additional locations, hub and spoke model) to cut down on the amount of heavy trucks needed to transport cement to direct consumers, and to reduce the distance the product must travel to businesses.

Great post!! Appeal for their new “insulating” concrete in developed markets is obvious. However, they can also sell it in lower income countries where power availability is unreliable so people can utilize this material to get the most out of their heating and cooling equipment