Building industrial-scale LEGOs using open innovation

How one company is fulfilling every engineer’s dream using industrial-scale LEGOs and open innovation

To solve a key pain point for manufacturers & design engineers globally, Vention has built a cloud-based machine design platform. An engineer can design, build, order, and receive his/her custom industrial machine all in less than a week, representing a 5x increase in speed over current solutions in the market [1].

Opportunity for technological innovation is ripe in an industry that has no clear market leader and has been grappling with flat growth for the past 5 years [2]. Through its public library of open-source designs, Vention can become a market leader that revolutionizes the way engineers design and build their custom industrial equipment.

A new way to design and build

The current process for an engineer to design equipment/machinery leverages traditional tools such as AutoCAD and typically takes several weeks, if not months, for an engineer to either scour bids from machine shops to understand how and/or if their suggested products will be compatible with their existing machines on-site or launch an entire engineering project to design from scratch a customized machine to solve a current need for the manufacturing engineer.

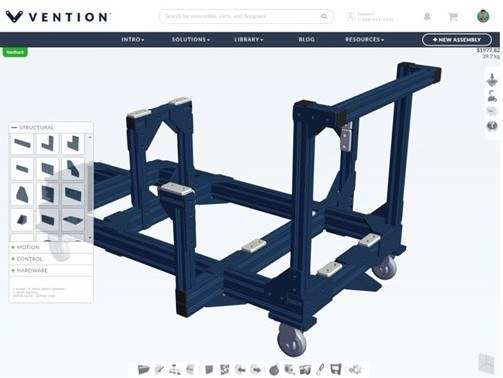

Vention’s 3D design platform offers a free solution for engineers to leverage pre-built designs of typical tooling components (jigs, tooling, fixtures, etc). Users can either directly order these components and/or build upon them to customize their equipment. Vention allows engineers to change what used to be a “complex engineering project to become a simple e-commerce experience”, by not reinventing the wheel each time they want customized equipment [3].

Using this AI powered platform, a user will have his/her bill of materials (BOM) automatically generated (vs manually managing a BOM of hundreds of pieces) as s/he designs the desired equipment. The platform automatically calculates the cost, weight, and number of fasteners required to assemble the equipment, allowing for full cost transparency [4]. Using artificial intelligence, the platform understands what the user is trying to build and offers recommendations for parts to use while building and it provides a 3D constrained system, ensuring assembly is error free for the user upon receiving the parts [5]

3D Machine Builder platform [Source: Kyle Maxey [5]]

3D Machine Builder platform [Source: Kyle Maxey [5]]

Content growth through open innovation

Vention’s value proposition transcends 3D modeling software. Instead, Vention offers significant reduction in time to market of equipment, simplified procurement workflow, and most importantly, reusability of designs, either those built by the users themselves and/or those available on the public library.

For companies and/or engineers looking to cut costs and time, having a pre-built library of structural, control, motion, and hardware components is a key advantage. To build its free public library of modular components, Vention has a small team of engineers who currently design most of the available public assemblies. However, users can also elect to have their designs be made public, whether they have built them from scratch or leveraged existing designs.

Vention’s public assembly library [Source: Author]

Vention offers royalties to its users who publish their designs to encourage this open source environment and to drive content growth. Users can earn 2.5% royalties whenever their designs are purchased, in the form of Vention credits, which can be later used to purchase other equipment [6]. Vention is using open innovation as a means of building its content library and helping users become engaged on its platform in a meaningful way, creating a community of designers and engineers.

Looking forward: Recommendations for Vention

Today, Vention offers access to its platform and pre-built library entirely for free, with its only source of revenue from product sales. In addition, its library is largely populated by its internal engineers.

In the future, Vention should look to have its platform become a self-run social marketplace, where users are driving most of the library growth, becoming an Amazon & Facebook for industrial machinery. One of Vention’s biggest value propositions is simplifying the design and ordering experience for engineers, by having all the steps occur in one spot, on the cloud-based platform. Expanding the product scope to more complex equipment (beyond simple carts, etc) should be a next step to continue to streamline the engineer’s design and procurement experience, by eliminating machine shops and other tooling suppliers that offer varying levels of quality and poor timeliness. One way to do this is inviting more collaboration from incumbent players in the market to offer their products on Vention’s platform.

Open innovation has been used to unlock value across many industries, to help solve the toughest of problems by crowd-sourcing ideas from virtually anywhere. Vention is on the right track but should push open innovation beyond using it as a nice add-on feature, encouraging more designers to join the community through, for example, competitions at universities, machine shops, and/or other engineering communities.

The main question that Vention faces moving forward: with additive manufacturing on the rise, how will Vention unlock value and monetize its AI-powered 3D Machine design platform?

(796 words)

Sources

[1] Tracey Schlemetic, “Meet 3D MachineBuilder, a Web-Based Platform for Speeding Custom Machine Design”, DesignNews, August 14, 2018 [https://www.designnews.com/design-hardware-software/meet-3d-machinebuilder-web-based-platform-speeding-custom-machine-design/120732718259259?utm_campaign=Weekly%20Newsletters&utm_source=hs_email&utm_medium=email&utm_content=65384576&_hsenc=p2ANqtz–RcSZh-75isgu6lxpq-zoLe2nHRaExINGs1Oyvpzgz6NT0lVYKv_dDfhjzwn5eLZ0HCiMPXnF15nTQbwGmL0Y13QW9Ig&_hsmi=65384576], accessed November 2018

[2] Tech Soft 3D, “Beyond 3D: Building Machines in the Cloud,” July 2nd, 2018, podcast, http://blog.techsoft3d.com/blog/beyond-3d-building-machines-in-the-cloud, accessed November 2018

[3] US Industry Market Research Reports: Metalworking Machinery Manufacturing, IBISWorld, accessed November 2018

[4] Josh Mings, “Vention.io is a Web-based Machine Builder Platform & Social Marketplace”, February 21, 2017, [https://www.solidsmack.com/cad/vention-io-web-based-modular-hardware-platform/], accessed November 2018

[5] Kyle Maxey, “Vention Has Launched an AI-based Machine Building Platform,” engineering.com, February 21, 2017, [https://www.engineering.com/DesignSoftware/DesignSoftwareArticles/ArticleID/14349/Vention-Has-Launched-an-AI-based-Machine-Building-Platform.aspx], accessed November 2018

[6] Vention, “Earn Design Royalties,” https://www.vention.io/blogs/73, accessed November 2018

Extremely interesting company! As a hardware engineer, this product definitely would have been a time-saver when I was designing prototypes and test racks. That being said, I would market the company as a resource for prototyping designs and keep their products simple. The advantage of doing this is two-fold:

1) Vention will not have to worry about having to provide complex structure, keeping costs down.

2) Vention can mitigate the risk of additive manufacturing imposing on their customer segment. In developing large prototypes and test racks, companies are really looking for a product that is cheap, fast, and gets the job done. I do not think that they would be willing to pay the funds required to create similar products via additive manufacturing.

This is an awesome company! I didn’t even know it existed, but it appears to be disruptive model due to quick turnaround capabilities. However, with a critical eye, I’m wary of Vention’s ability to scale through open innovation. As more engineers collaborate and sign up with their designs, does Vention, currently a smaller-scale startup, have the wherewithal to accommodate the variability in a wide range of design options? Is there a capacity threshold where the company would have to consider rejecting designs due to the high fixed costs incurred to acquire the tooling to create the new designs? If the spirit of open innovation is to drive new ideas through a scaled base of engagers, Vention’s cost structure will be a critical determinant going forward.

Great example of how the upcoming technological revolution across industries is using open innovation to boost scale and innovation. However, this particular example where a substantial amount of technical knowledge is required to innovate new machine ideas, do companies like Vention need to provide a way for intellectual property protection of their developers?

Really interesting! As you suggest, it seems like Vention is using open innovation more to drive its sales than to create a true open marketplace for designs. I’m not sure that monetizing the platform is really necessary, as long as costs for the effort are covered as marketing/sales costs for their product sales. I agree that universities would be a great way to expand the library; Vention could also add some “expert” designs that they sponsor. (Are there influencers/thought leaders in this space?) However, I’m not convinced that competitors/incumbent players would participate, unless Vention manages to change the industry so much that these players are fighting for survival.

On your latter point, that is what I thought as well. But according to a recent podcast by the CEO, he was suggesting that branded players are trying to get on their platform. Would be interesting to understand why they’re using Vention as a channel?

Where is my engineering degree when I need it? What an amazing way to drive innovation in an industry that has been grappling with flat growth for five years. This is an innovative way to become a clear market leader. One of the things I really like is the fact that Vention is allowing those who iterate on their designs to share in their profits. Because contributors have the potential to be compensated for their contributions, I imagine the quality of contributions would be high. I can see other industries copying this model and getting high-quality ideas from a variety of customers/contributors.

Fascinating read- and you covered all 3 topics! I’ve personally felt this pain before and completely agree that the entire process is ripe for disruptions. What would make it even more interesting though would be partnerships with company’s such as Protolabs. Protolabs does instant quoting on machined components. I think it would marry well with the LEGO approach and allow them to offer a complete solution. It would be quite incredible if every company did this to some degree. Arguably it would erode competitive positioning, but I wonder how much better off it would make the entire human race?

When I think about crowdsourcing, I am always wary about quality of ideas or product. In this case, Vention is currently relying upon a small team of engineers to design most of the public assemblies; however, you argue that to push open innovation past being a nice add-on feature, they should increasingly encouraging more designers to join the community and add to the library. With this suggestion, Vention must also ensure they can maintain moderation a baseline design standard to ensure their customers are receiving high-quality products. Thus on one hand, Vention may benefit from a wider catalog and perhaps more complex set of designs, but they may also be negatively affected if they are not able to successfully vet out designs that do not meet a certain standard. Thus for a community like this to take off, Vention must focus on creating trust with their customer base – have they been able to do this to-date and what will they have to do to maintain this level of trust? Will they moderate the quality check on their own or will they have users self-moderate via reviews like Amazon?