AI and Predictive Analytics: The Internet of Things at Work in the Trucking Industry

Following a long history of production processes that occurred within plants, the digitalization era is allowing trucking manufacturers to extend their supply chains beyond point of sale.

The heavy machinery manufacturing space has for a long time relied on the same schematics of supply chain processes: source raw materials, process and assemble them, and ship the finished good to a customer [1]. The advent of digitalization is now allowing manufacturers to push customer service involvement beyond the point of sale, and throughout the entire useful life of the machine. Specifically, the trucking industry is catching up to its obsolescence and is embracing growing demands from customers through Internet of Things (“IoT”) enabled technologies.

Digitalization in Supply Chains

One breakthrough technology in supply chains is anchored around predictive analytics. Supply chain innovators such as Amazon have been using this specific technology to get inventory close to a customer as soon as the item would be placed in an online basket, on a wish list, or based on past behavior [2].

Digitalization at Navistar

Navistar International (“Navistar”), a large manufacturer of commercial trucks, buses, and defense vehicles is one of those players who are constantly looking to develop an edge over competitors. Navistar has adapted an Amazon-like approach through a GPS-enabled telematics technology to predict where machine parts will be needed in the country. Thanks to this, Navistar can optimize its supply chain and reduce lead time for new parts [3]. The Company however did not limit its use of technology to inventory management.

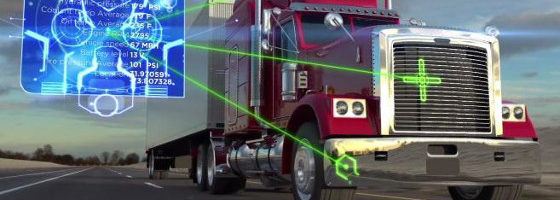

In order to remain a top innovator, Navistar’s management has developed partnerships with technology firms. Most recently, the company has partnered with Cloudera, a provider of modern platforms for machine learning and advanced analytics to revolutionize customer service in its field. Navistar now has full visibility of over 300,000 vehicles. The now IoT-enabled connected vehicles are diagnosed in real time, and Navistar can help customers essentially fix trucks before they break, thereby reducing maintenance and downtime costs by up to 40% [4]. Customers have historically relied on fixed maintenance schedules, which intuitively does not make sense, given that machines do not break on a set schedule. The use of IoT in this context will allow customers to better squeeze value out of their assets.

Other benefits that digitalization can bring include potential improvements in fuel efficiency, and better mobility through “on-the-road repairs” [5]. By providing ongoing maintenance services to various customers, Navistar can differentiate itself and create deeper customer relationships. The heavy use of IoT can also present significant additional opportunities, including valuable data collection, which can in turn be leveraged to further ameliorate manufacturing processes.

Scale, Scale, Scale!

Digitalization in the manufacturing space rarely constitutes a sustainable competitive advantage. Companies must continue to look for new avenues to innovate. As Artificial Intelligence (“AI”) around automated driving improves, Navistar should leverage its IoT-enabled technologies to go beyond improving maintenance. Predictive analysis can be used to address safety issues by improving safety-related decision making remotely [6]. This represents a clear avenue that would create additional value for the customer from a human perspective (literally saving lives from reducing accidents), but also from a capital perspective (minimizing repairs and replacements).

An ancillary application to this technology could be extended to the insurance industry. By virtue of the collection of data mechanism, IoT can serve to “personalize insurance rates, detect crashes, improve the claims process and enhance customer relationships” [7]. Insurance companies will most likely find the ability to further segment customers in a granular fashion. Monetizing IoT would represent a clear opportunity for heavy machinery manufacturers such as Navistar to develop additional sources of income.

Are There Limits to Scaling?

The opportunities that stem from the use of IoT seem abundant, but an over reliance on technology may actually end up becoming counter-productive. Navistar’s competitive advantage remains in machine manufacturing, not in data analysis or data storage. The benefits of scale are obvious, but Navistar should carefully build relationships with technology partners such as Cloudera. Navistar will need to leverage these third-party capabilities in a manner that is efficient and additive to its supply chain.

Going Forward

While Navistar has showed proactivity in terms of being an early adopter of disruptive technologies in the trucking and heavy machinery space, innovation is such that one can never be complacent. Where is the next wave of innovation going to emerge from and how should Navistar position itself in a way to capitalize on those potential opportunities?

(717 words)

References:

[1] Yogesh Malik, Alex Niemeyer, and Brian Ruwadi, “Building the supply chain of the future,” McKinsey Quarterly, January, 2011, https://www.mckinsey.com/business-functions/operations/our-insights/building-the-supply-chain-of-the-future, accessed November 2017

[2] Praveen Kopalle, “Why Amazon’s Anticipatory Shipping Is Pure Genius,” Forbes, January 28, 2014, https://www.forbes.com/sites/onmarketing/2014/01/28/why-amazons-anticipatory-shipping-is-pure-genius/#59830e044605, accessed November 2017

[3] Bruce Rogers et al., “Digital Supply Chain – Are You Leading the Pack?”, Forbes Insights, in association with: Cognizant, 2017, https://i.forbesimg.com/forbesinsights/cognizant_supply_chain/Digital_Supply_Chain.pdf, accessed November 2017

[4] Cloudera, Inc., “Navistar’s IoT Deployment on Cloudera Wins TDWI 2017 Best Practices Award,” July 21, 2017, https://www.prnewswire.com/news-releases/navistars-iot-deployment-on-cloudera-wins-tdwi-2017-best-practices-award-300492324.html, accessed November 2017

[5] Sundeep Sanghavi, “Optimize Fleet Management with Predictive Maintenance,” JOC Group, Inc., July 9, 2017, https://www.joc.com/technology/optimize-fleet-management-predictive-maintenance_20170709.html, accessed November 2017

[6] Grace Suizo , “Using Predictive Analytics to Improve Fleet Decisions,” Automotive Fleet, September, 2015, http://www.automotive-fleet.com/channel/gps-telematics/article/story/2015/10/using-predictive-analytics.aspx, accessed November 2017

[7] Business Insider, “Leading Businesses Rely on Cloudera for Machine Learning to Drive IoT Innovation,” September 28, 2017, http://markets.businessinsider.com/news/stocks/Leading-Businesses-Rely-on-Cloudera-for-Machine-Learning-to-Drive-IoT-Innovation-1002727738, accessed November 2017

Thanks for sharing this post! I see it is a success story about how a company that doesn’t have technology at its core business can use technology as a differentiator. In fact, it’s common to think that cutting-edge technology such as Artificial Intelligent systems will only help old business models get disrupted. Your post captures the essence that this reality doesn’t have to be true. There are software companies that specialize in helping established business compete with technology-born businesses.

Cognitive Scale is a good example of this companies. Among their products, they offer SaaS to help analyze Big Data and IoT data. Check this white paper to see how other companies are using that similar to what Navistar is doing: http://www.cognitivescale.com/wp-content/uploads/sites/4/2015/02/Cognitive_Scale_Brochure.pdf.

On the other hand, one question that puzzles me on this topic is that all the trucks are traveling IoT and Navistar is using Cloud Computing startups as partners to process their data. How is the company thinking of the risks associated with that? There is a clear fear in the market that the threats associated with IoT are far from being dealt with (https://www.mckinsey.com/business-functions/digital-mckinsey/our-insights/protecting-information-in-the-cloud).

As to your question about how Navistar should capture the new innovation waves, two common responses that they could do are: i) partnering with a Venture Capital firm to have a pulse on the innovation in the market; ii) launch their internal Venture team to directly invest in new companies.

Thanks for an informative read! I do not know much about trucking industry but the the broader application of GPS-enabled telematics technology is really interesting to me. Most of things transported in trucking industry are food services and I can see how this sensor can also be used to manage food supply management and informing better stock management for companies. It’d be fascinating to explore where this technology goes.

Very interesting article – thanks for the read. I certainly agree that technology should enable dramatic improvements in supply chain performance – particularly, as you point out, in demand forecasting (e.g., predictive analytics) and asset utilization (e.g., IoT telematics that predict maintenance needs in advance).

In my view, the biggest untapped opportunity in trucking logistics is in autonomous driving. You allude to this in your article, but I would emphasize its transformative potential even more. Many industry analysts agree that the “short term” impact of autonomous driving will not be to eliminate drivers altogether, but rather allow them to operate cars remotely. This innovation would (a) provide drivers a better quality of life, (b) improve roadway safety, and (c) allow for redesign of trucks to eliminate the drivers’ seat cabin and create greater fuel efficiency.

Further reading on this topic below:

https://www.freightwaves.com/news/2017/5/31/drivers-and-autonomous-trucks