Adidas in the 3D Printed Race – When Size Does Not Matter

Adidas, one of the world’s largest sportswear manufacturers, is betting on 3D printing to create the next generation of bespoken sneakers for individual customers. Will we see a future when size charts become redundant, and “custom-fitted haute couture” no longer equates exclusive luxury?

3D Printing in Clothing

In recent years, the use of 3D printing has become increasingly popular in high-end fashion, particularly for haute couture collections (Exhibit 1) where creative constructions of unusual fabrics are highly valued. By relying on computer software to add successive layers of materials, designers are more willing to tackle complex designs and cutting techniques.

Although the same trend is not yet as apparent in sportswear fashion, mastering 3D printing can offer Adidas an edge in process management and product development. First, 3D printing reduces the cycle time, because production is processed entirely by a machine and eliminates the complexity of assembling multiple parts to create the finished goods. As a result, products are often produced “on-demand”, decreasing both excess inventory risk and storage cost [1]. Second, because it limits variabilities due to human errors, and every detail is pre-calculated on the computer, 3D printing improves yield rate, translating to less material scraps and higher product quality.

Because the cycle time is shorter, and complex techniques are made easier with 3D printing, 3D printing facilitates the creation of smaller batches of sneakers customized to singular needs [2]. This is crucial for sportswear, as every athlete has different needs to optimize their performances. Furthermore, by offering customization, 3D printing also allows customers to co-participate in the product development. Given that people often place a higher value on the items they own and develop, Adidas can leverage this endowment effect [3] to charge a higher price and earn a better margin.

Adidas’s Strategy

After conducting several researches to understand different sports requirements, Adidas found that to perform at their best, athletes need different points of density throughout their midsole. However, with traditional manufacturing, the process of assembling multiple parts of foam with varying densities for midsoles is highly labor-intensive and introduces several potential points of failure[4]. Confronted with this challenge, Adidas decided to collaborate with Carbon (a 3D-printing company) in 2017 to experiment the possibility of 3D printing midsoles.

Applying a method called Digital Light Synthesis (DLS), Carbon’s machines use digital light below the printing surface to shape liquid resins into the sneaker’s midsoles and start printing layer by layer from the bottom[5] (Exhibit 2). Dr. DeSimone, CEO of Carbon, claimed that this method defied the traditional 4-step cycle (design, prototype, tool, production) and made it possible to go directly from design to production[6].

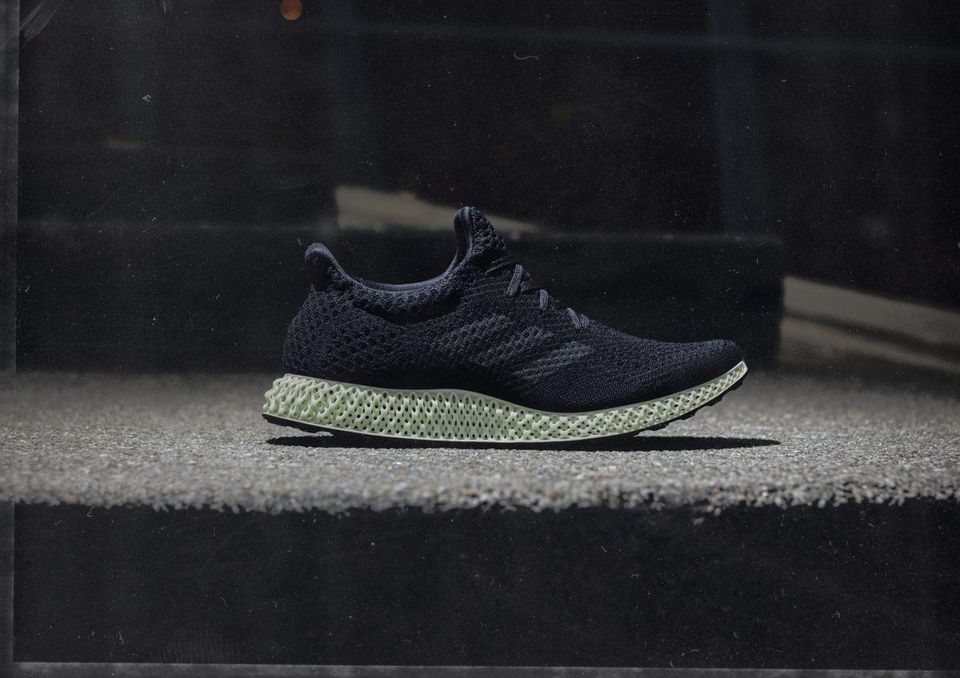

In January 2018, Adidas released its first 3D printed sneakers – Futurecraft 4D (Exhibit 3), calling it the “world’s first high performance footwear featuring midsoles crafted with light and oxygen”[7]. The shoes were sold out within the month, leading Adidas to set a goal of one million pairs of 3D-printed sneakers, before expanding to other areas of sportswear in five to ten years.

Recommendations

Given the promising post-launch reception, in the short run, Adidas should first secure additional capacity from Carbon to scale up the production quickly and benefit from lower unit costs through economies of scale. As a result, Adidas will be able to cut the shoe price, enabling Futurecraft 4D to reach many more customers. In addition, Adidas should pilot setting up feet scanners at its network of retail stores and have customer run on a treadmill to provide biomechanical information[8]. This action will serve two purposes: First, Adidas can use these scanners as a marketing tool to raise awareness and educate customers about this new technology. Second, the data collected will help Adidas further test the feasibility of customizing shoes to individual needs.

In the long run, Adidas should invest in R&D to overcome the current rigidity constraint of 3D printed materials and consider applying the technology to more flexible garments[9]. This will allow Adidas to tailor not only the soles but also the other parts of the shoes, delivering a comprehensively customized product for every customer. This will open a new segment of high-end bespoken sneakers, where Adidas can potentially rival the likes of Chanel and Gucci in delivering haute couture services.

Open question:

One of the biggest challenges that 3D printing poses to Adidas and the general fashion industry is intellectual property (IP) infringement and counterfeiting[10]. As the technology becomes more readily available and portable, counterfeiters can use 3D scanners to create illegal copies of Adidas products and move operating sites quickly to eschew law enforcement. What can Adidas do to fully monetize their inventions and ensure that innovation would not suffer as a consequence of violated IP?

Word Count: 756

[1] Amandine Richardot, “Everything You Need to Know About Additive Manufacturing, and What Can Be Done When Applying 3D Printing to Fashion,” Futur404, January 19, 2018. https://futur404.com/3d-printing/

[2] Allan Joseph, “Adidas Futurecraft 4D, and Why It Shows Adidas Isn’t Playing Defense When It Comes to Fashion Tech,” Futur404, April 26, 2017.

https://futur404.com/futurecraft-4d/

[3] Plott, Charles R; Zeiler, Kathryn, “The Willingness to Pay–Willingness to Accept Gap, the “Endowment Effect,” Subject Misconceptions, and Experimental Procedures for Eliciting Valuations”. American Economic Review. 95 (3): 530–545, 2005.

[4] Sarah Tolle, “adidas Unveils Industry’s First Application Of Digital Light Synthesis with Futurecraft 4D”, CARBON press release, April 7, 2017.

https://www.carbon3d.com/news/adidas-unveils-industrys-first-application-of-digital-light-synthesis-with-futurecraft-4d/, accessed November 2018.

[5] Fitz Tepper, “adidas Latest 3D-printed Shoe Puts Mass Production Within Sight,” TechCrunch, April 7, 2017.

https://techcrunch.com/2017/04/07/adidas-latest-3d-printed-shoe-puts-mass-production-within-sight/

[6] Gina Hall, “Adidas Partners with Silicon Valley Startup to 3D-print Shoes,” BizJournals, April 7, 2017.

[7] “Adidas Unveils Industry’s First Application of Digital Light Synthesis with Futurecraft 4D,” Adidas Group press release, April 7, 2017.

https://www.adidas-group.com/en/media/news-archive/press-releases/2017/adidas-unveils-industrys-first-application-digital-light-synthes/, accessed November 2018.

[8] Andria Cheng, “How Adidas Plans To Bring 3D Printing To The Masses,” Forbes, May 22, 2018.

[9] Amandine Richardot, “Everything You Need to Know About Additive Manufacturing, and What Can Be Done When Applying 3D Printing to Fashion,” Futur404, January 19, 2018.

https://futur404.com/3d-printing/

[10] Herbert Sim, “3D Printing In Luxury Fashion: Revolution Or Evolution?,” Forbes, December 3, 2017.

Great essay, completely agree that 3D printing in shoe manufacturing will lead to highly customisable products suited to the needs to individual athletes. However one question that remains is what will be Adidas’ competitive edge over other major players such as Nike or Puma, who have similarly successfully launched 3D printed shoes as well. While this will expand the industry as a whole, gaining competitive edge over rivals seem difficult.

With respect to your point on counterfeiting, one possible solution can be to integrate RFID trackers within the sole of the shoe, each of which will have an unique identification number that can be verified using an app through the consumer’s smart phone. I know that Salvatore Ferragamo did this some time back, inserting a small tracker in the left sole of women’s shoes. Can a similar approach be taken with 3D printed shoes as well? (Manufacturing feasibility of integrating electronic item during 3D printing needs to be checked)

Thanks for the great read. I believe 3D printing will have a huge impact on the inventory management of shoes. Being able to print shoes on demand at the store or in a nearby facility will greatly reduce the instances of shoe sizes/models being out-of-stock. Stores will also be able to run on lower inventory, allowing for more space to be dedicated to retail display.

Perhaps one solution to preventing counterfeiting is to control the raw material itself. I would imagine Adidas uses some sort of proprietary blend of plastics to achieve its desired structural performance in the shoes. Retaining control over this raw material stock would prevent counterfeiters from reproducing their work in any realistic way, even if they somehow gain access to the blueprints.

Great note, thank you for the read. My biggest worry for the clothing industry in regards to 3D printing is the possibility that the barriers to entry in this business collapse. One of the reasons it is so difficult to enter the shoe business for instance is the level of fixed cost needed to invest to produce a X amount of shoes. If I were able to buy a 3D printer (eventually) for a reasonable cost, why would I not try to produce most of my clothing through it? Same for someone who wants to start a shoe business and has limited capital but would like to control the manufacturing, they could acquire a 3D printer. In addition, given the cost to produce (due to time) declines, will pricing decline by the same or even more? These are both worries of mine, but I understand the innovators dilemma.

I think this article does a great job of spelling out several important benefits to 3D printing for Adidas: (1) lower costs through “on demand” production which reduces excess inventory and storage, (2) higher product quality due to elimination of human error and ability to layer on new materials, and (3) a greater degree of personalization which endears users to the product and increases brand loyalty and willingness to pay.

However, I worry about Adidas’ true competitive differentiation given they are using a third party – Carbon – for their 3D printing needs. I believe a source of differentiation would be around their ownership of unique 3D printing technologies that can create shoes in different styles than competitors. The fact that Adidas appears to be outsourcing this technology today worries me in that Carbon controls the IP and could license it out to a competitor like Nike, thereby revealing Adidas’ trade secrets and exposing its products to replication. Should Adidas buy Carbon? A vertical integration strategy around 3D-printing might make sense to protect its IP and to more easily extend into product categories beyond shoes.

Your question around counterfeiting is a good one. Based on an OECD-EUIPO report from 2013, it appears that footwear is the most counterfeited good in the world, ranking ahead of clothing, leather and electrical machinery. I would suspect, as you point out, that 3D-printing makes it even easier to counterfeit. To address this issue, I’d use the advances of 3D-printing to make products even more customized, such that Adidas is able to regulate and manage the supply of a certain product it introduces. For instance, it could tag each product with a unique number so that a buyer knows it’s one of X number of versions of the product that Adidas has released. Furthermore, the company could control its distribution of the product – e.g., make certain products only available through the Adidas online store – so that customers know they are purchasing authentic versions of the product. While counterfeiting will likely continue to be an issue for Adidas, leveraging advances in 3D printing to further customize its products and investing in unique 3D-printing technologies which smaller counterfeiters can’t replicate will be important steps in ensuring the continued success and authenticity of the brand.