Adding Value In Nike’s Production Line

With Nike pushing Flyprint, Adidas working with Carbon 3D, and New Balance tapping into Formlabs for partnership, why is this seemingly commoditized footwear market looking to 3D printing?

The Additive Manufacturing (3D Printing) industry has been quite a roller-coaster over the last several years. Despite some evangelists touting the potential to disrupt the entire supply chain and “… slash the time needed to order tools, jigs, and fixtures,”[1] 3D printing companies still only seem to have found very niche areas for application, namely prototyping and some aviation products. Some of the latest interest seems to point to the shoe industry, with Nike publishing articles on Flyprint[2], Adidas working with Carbon 3D on midsoles[1], and New Balance tapping into Formlabs for a partnership[3]. But why is this seemingly commoditized market looking to 3D printing? To understand how Additive Manufacturing (AM) can find mainstream adoption in shoe manufacturing we first need to dig into the unit-cost metrics.

Unit-Cost

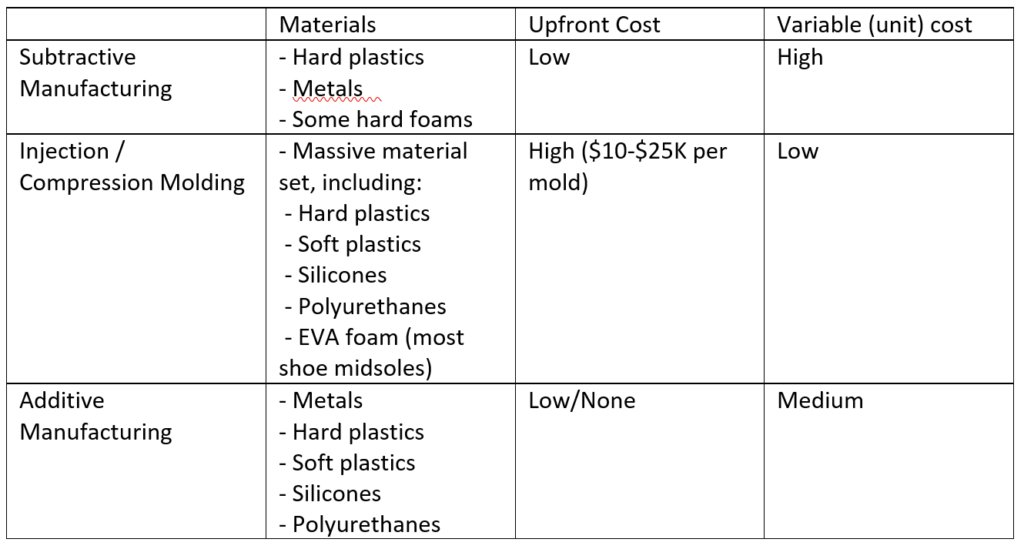

When a company such as Nike designs a mechanical component there are a few options on how they can get it manufactured. A simplified list might include:

Subtractive Manufacturing – Starting from a block of material, machine away the exterior until the desired design is left. This still a fairly manual process, typically requiring multiple operations to release and rotate the material in order to get every plane. This can only be done with hard plastics, metals, and some hard foams. This process is often done for low-quantity orders that have very tight specifications or material properties.

Injection or Compression Molding – In this process, one starts by machining a metal mold (usually either aluminum or steel) into the negative of the desired shape of the product. Then molten plastic or a fast-curing material is injected into the mold, allowed to cool/cure, and the mold is opened to eject the component. The material set for this process is extremely broad. There is a high setup cost, with production molds typically running between $15k – $25k. Once these tools are up and running, it’s very quick to get parts produced – often well under a minute.

Additive Manufacturing – This involves building a part one layer at a time, and stacking those layers to form a completed part. Depending on the process, the layers can be from 50um to ~1mm. This process typically takes significantly longer than injection molding and often even subtractive methods. The time depends on a lot of factors, but namely the volume of the part being produced. The same part produced using injection molding in under a minute could take several minutes to an hour using common 3D printing techniques.

When manufacturing a product using molding, the tooling cost is fixed, and thus at a per-unit cost will just be divided by the number of units products. At quantities above 100k, the relative cost of a mold becomes vanishingly small.

How This Applies to Nike

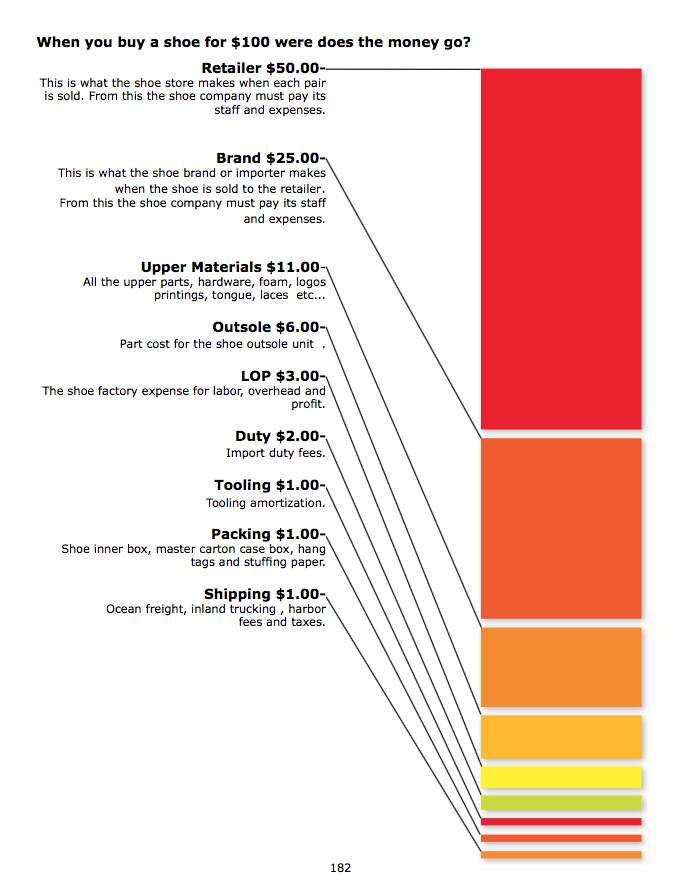

Nike sells $21.1B in shoes per year [4]. Assuming an average price of $100 then they are producing in excess of 200M pairs of shoes annually (380 shoes per minute). At first glance, this would fall well into high-volume production territory where AM cannot compete with molding, however, the unique aspect about the shoe industry is just how many product offerings they supply. RunRepeat.com[5] shows a total of 929 different products for Nike. Each of these shoes is offered in a range of sizes, from 5 to 15. Assuming they offer ten different sizes for a typical product, we end up with about 10,000 different SKUs (stockkeeping unit). This means the average design sells around 20,000 units and a unique mold is required for each product/size. If we spread the $20,000 mold cost across each unit produced, it runs about $1 per pair of shoes.

A single 3D printer able to produce a pair of shoes every 30 minutes with an 80% up-time would create around $1.00 x 2(units/hr) x 24(hrs/day) x 365 (days/yr) x 0.8 = $14,000 of value per year in molding costs alone. This assumes the cost of materials and labor remains the same as molding. Starting to replace low-volume product assembly with 3D printing could dramatically reduce the overall production cost.

Saving on mold cost is only one potential benefit in this industry. Consider that Nike might be able to better integrate or automate potential AM systems [3], reducing labor costs by up to $3 per pair of shoes (below). Automation and a simpler, cleaner process could also allow for shoes to be manufactured closer to the end point of sale, saving up $3 on import duty and shipping (below). Further, a lower lead-time can result in reduce inventory carrying costs and allow the company to react faster to consumer trends. Tallying this up, it is no wonder why Nike is investing in new additive manufacturing technology, like Flyprint[2].

https://www.youtube.com/watch?v=RFW35vTTGQI

(Word Count: 777)

[1] A. Brown. Chain reaction: Why additive manufacturing is about to transform the supply chain. Mechanical Engineering 140, no. 10 (October 2018): 30–35.

[2] https://news.nike.com/news/nike-flyprint-3d-printed-textile

[3] https://formlabs.com/company/press/formlabs-and-new-balance-come-together-3d-print-high-performance/

[4] https://www.statista.com/chart/13470/athletic-footwear-sales/

[5] https://runrepeat.com/ranking/rankings-of-sneakers

[6] Motawi, Wade. How Shoes Are Made: A behind the scenes look at a real shoe factory, CreateSpace Independent Publishing Platform; 3rd edition (November 18, 2015)

[6]

[6]

I agree with your analysis that additive manufacturing techniques can improve Nike’s cost profile. However, I also see a more significant opportunity for Nike outside of additive manufacturing. Looking at the shoe cost bar, 50% of the price is consumed by an intermediary, the retailer, in order be a POS for the shoe product. Why can’t Nike sell direct to consumers and reduce price? It seems that this would allow for significant market share capture from their close competitors. I don’t think the brand image would be dented by shifting to DTC. A quick google search actually indicates that Nike is making a DTC push, so maybe it won’t be long before we no longer have to pay a 50% markup to a middleman?

You’re not wrong. I think the industry should certainly be worried about DTC competition like Allbirds. These companies hit on a different customer values. Instead of individualization and “aspiration” we talk about these companies offer pragmatic value and socially responsible sourcing. I definitely don’t see the need in Nike offering 1000 different sneakers, but some people must see the value.

Still, a vast majority of the retail volume is still driven through brick-and-mortar distributors, and the companies like Footlocker have a lot of control over how they push Nike’s product. Nike has to be careful not to burn that bridge too soon.

Interesting article! Additive manufacturing in the sport field, shoes specifically, has seen great progress over the past couple of years.

What would be interesting is to see whether these companies might even expand into allowing customers to customize their own shoes that are then printed a couple of days later.

The technology should be advanced enough, but I wonder whether that would be a lucrative business model

Yeah, this definitely hit’s on the shoe industry’s aim to make customers feel unique. I know of companies that develop scanners that will measure your foot and customize shoes, so I think the industry is moving that way. Still, the unit-cost metrics need to make sense, because I don’t think there is enough fundamental value in that product to warrant a significantly higher price-point.

In my previous career we threw around the idea of printing custom designs on football (soccer) cleats that would allow customers to specify the pattern on the top of the cleat which would effect how you strike the ball.

Great article! Compelling argument on why a company that cranks out 200M shoes per year is focused on unit cost. Initially my thoughts on 3D printing in the shoe business jumped to custom colors on classic shoes. This would enable teams and individuals to match shoes to their uniforms and/or outfits. Possibly removing issues of “Nike doesn’t have this in my teams colors.” Customization might attract new interest to your brand or remove barriers to buy a new pair of shoes, but it cannot come at the sacrifice of higher cost when you make 200M shoes per year.

Really cool article. This type of application for additive manufacturing makes me think of how manufacturing can become increasingly decentralized in decades to come. Looking at your cost estimates for packaging, shipping, and retailer margin, I can see a future where individual households can have their own manufacturing capabilities in the form of highly-advanced 3D printers. In this model, individuals could purchase shoes as digital CAD files from companies like Nike and simply print their shoes at home, completely circumventing the traditional supply chain and saving costs as a result.

I really like how you begin by comparing and contrasting three different manufacturing methods. I agree that with 3D printing, Nike can reduce shipping/duties and inventory carrying costs by being able to manufacture shoes closer to the end point of sale. I think another benefit is that there is a lot less waste in terms of materials such as fabrics when 3D printing. In our marketing case we learned that Nike wants to focus on sustainability — and from my point of view, 3D printing can be a selling point for all the reasons you listed above.

I thought this technology could be really compelling for high end performance footwear and rapid prototyping. I could envision a scenario where a long distance ultramarathon team takes data generated while running and uses it to make tweaks to the digital files for the shoe and print new versions of the shoe during the race, adapting to the conditions on the go. Or imagine printing a new version of your cleats at halftime when it has started to rain or snow that have additional grip and support. I thought the cost breakdown was really interesting as well- had no idea that retailers took half the cost of the shoe. Very nicely written.

Timely article! You do a good job of elucidating the potential cost advantages to Nike of moving to more use of additive manufacturing rather than traditional injection molding, but I wonder about the time impact. From my limited understanding I would expect 3D printing to be slower than traditional injection mold manufacturing, and so the big question is – does the unit cost differential adequately compensate for the loss in output volume?

Your post is fascinating and eye-opening as far as the applications of 3D printing. I imagined that Nike was building entire shoes from the sole up with a single machine. But their process makes 3D printing seem complementary to existing manufacturing processes, which are driven by assembling numerous pieces together. The soles are made in one place, the fabric sides & upper in another. I wonder if Nike could save cost and continue building their assortment through leading the charge in 3D printed fabrics. Are there particular textiles – and at a higher level, consumer benefits like insulation/comfort/breathability- that can only be achieved through this method? I am excited to see how else Nike embraces this technology moving forward.

It is pretty impressive what additive manufacturing can do. While I strongly believe this could be a plus to Nike’s production cost, I believe we need to broaden our scope and reflect more on the broader picture here which is the fact that additive manufacturing introduces a ton of benefits outside of costs if only we could get it right.

Additive manufacturing not only reduces cost but also increases a lot of flexibility to Nike’s production system which subtractive manufacturing and injection moulding cannot do. In this age of varying customer demands and increasing need for customization of commodities for varying customer segment, this could be a competitive edge for Nike.

In addition to flexibility, Nike could leverage this technology to print sustainable and eco-friendly sneakers – this could be their product and brand differentiation. Having this technology could also drive crowd-sourcing innovation in this space. I look forward to walking into any Nike store and printing my own sub-branded Nike sneakers.

I thought your point about shipping was particularly good. We tend to look at 3D printing as this groundbreaking new technology for its advances in materials, prototyping, and design, but being able to move a factory closer to the point of sale may have a bigger effect on the bottom line that the more commonly discussed advanced. This point would be an interesting addition for classes in the future when people discuss the effects of automation on our economy. It’s usually focused on questions of labor, but we rarely consider questions of shorter supply lines.

Wonderful Article!

As described in the link below, the shoe manufacturing process involves a lot of manual work.

https://sneakerfactory.net/sneakers/2018/01/how-does-a-factory-make-shoes/

3D printing technology has the potential to change the process drastically. Moreover, sneakers can be more technology oriented if manufacturers apply 3D printing in their manufacturing process. I really wish to know more about the progress in this area in the future!

This is an interesting read, especially after our Nike case that talks about the company’s goal to constantly innovative. 3D printing technology is a great way for Nike to improve its manufacturing process and save costs It’s also very interesting to see how the revenue of $100-dollar shoe is broken down into different costs. If 3D printing is to gain popularity in the shoe industry in the future, margin will increase drastically especially for large firms like Nike given even small amount of savings per shoe manufactured is significant to impact its bottom line.

Awesome post! Great analysis of how the vast numbers of SKUs may provide a unique benefit of implementing AM. One concern i have is that my experience with 3d printers is that the resolution of the finished good is not good enough to ship directly to consumer. I would expect Nike would need to add finishing processes to refine parts made with AM before they were acceptable to ship out. An alternative might be using 3d printers to create the molds for the many different SKUs. This might also save time as the 3d printer could create a mold that is close to the required near-net shape, and then traditional machining could finish the mold, instead of having to make the mold from a standard billet and machine away the entire cavity.

Great article! I am a huge fan of Nike so it is great to learn that they are innovating in this space using this technology. My question is around capacity of 3D printers. 3D printing is an incredibly time consuming process. Even if they are able to improve efficiency to the point that they are cost competitive using 3D printing – will they be able to meet customer demand for mass products? What happens when they have a hit product for which demand sky-rockets? Interesting topic, thanks!

Hi Kyle, thanks for sharing this interesting information! In addition to the cost advantage of 3D printing for Nike, I thought it might also have the added benefit of speeding up innovation. In some other industries I’m familiar with such as lighting profile, it can take several weeks or months for a molding or die shop to create the necessary tooling for a new product. Depending on the situation, there may be a backlog, and you will have to wait in line in order to have the supplier create the tool you need. using additive manufacturing, Nike can accelerate the testing and manufacturing process for a new shoe without having any tooling delays