3D Printing and Humanitarian Aid, Will the US Learn from Past Disastrous Response?

I argue that the standard US response to disaster (i.e. Puerto Rico) could be drastically improved by incorporating Additive Manufacturing in relief efforts.

Following natural disasters, US Humanitarian Aid Organizations take an outside-in approach to relief. We funnel donations of goods and supplies through US organizations, and create a supply driven economy that results in planes [i] and crates full of wasted goods [ii]. The predominant issue is a broken supply chain, where demand arrives in one spike immediately post disaster, and is met with a full-scale standardized response of goods and services that ignores localized need, may arrive weeks after the initial event, and absorbs 60-80% of aid dollars in logistics costs.[iii] One solution to these shortcomings is 3D printing.

3D printing is a localized, real-time solution to demand for goods and services in disaster areas. Augmented Manufacturing (AM) machines can produce multiple products with a single source of raw materials and no retooling time. [iv] This means that one user on the ground, properly educated, could eliminate the need for multiple shipments of medical, sanitary, or infrastructure supplies. For example, a local community may need replacement parts for crutches or glasses, or they may need umbilical cord ties, or a new water pipe fixture to restore access to fresh water. These products, while immediately useful, would take weeks to arrive in a traditional relief structure, but can be produced immediately and exactly according to demand (with no damage from shipping) using AM. [v]

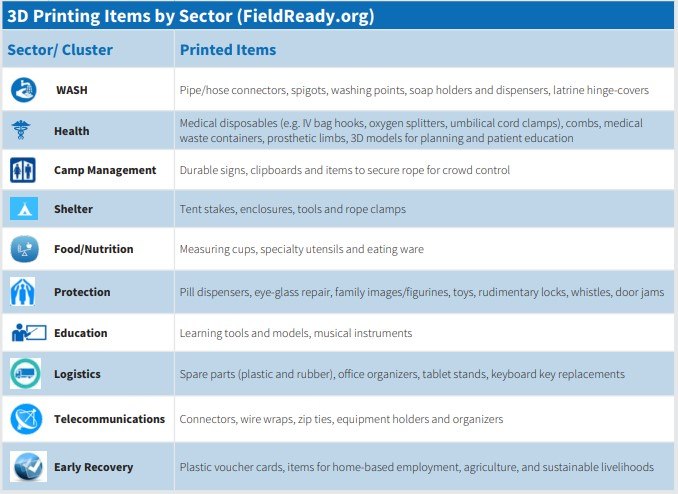

List of 3D Printing Items as of 2015 from Field Ready.org:

One NGO called “Field Ready” is leading the charge on Humanitarian AM. Field Ready partnered with World Vision (an independent aid organization) in Kathmandu to repair relief cook stoves that had been damaged in shipping. Instead of waiting additional months for a new set of cook stoves, with no guarantee that the replacement stoves would arrive intact, Field Ready provided 3D printers to create replacement parts on site. In addition, they developed an app that scans a broken pipe opening, feeds that information to the 3D printer, and creates a complementary fitted pipe to improve access to water immediately following disaster.[vi]

While private innovation has taken root, US governmental response to disaster has remained inefficient. Large scale efforts to improve the relief supply chain have focused on the front end of the chain (i.e. planning, procurement, and shipping of goods), and the solution has been a shift to cash donations because they are the most flexible form of aid. [vii] This shift to cash enables local governments to help determine supply of goods for their regions, however it does nothing to solve the underlying issue of damages and delays in shipment, or the need for real-time customized response.

The other way the US provides aid is by donating sizeable sums of money to construction or infrastructure projects. The issue is this money goes to US company contracts, and does little to bolster the local economy of the disaster area. This is most recently displayed in Puerto Rico, where 90% of the $5 billion of aid disbursed to date has gone to US based companies, instead of local companies that could benefit from an injection of capital. [viii]

Moving forward, the US must focus on local solutions that include disaster relief education programs, AM machines, and training locals in the use of those machines (see endnote [ix] for an example training document). Disaster relief education should be mandatory and accessible online to both US first responders, and to the general public of the country in need. Many European nations have instituted a requirement for uniform first responder training; if we were to do the same, and include AM training in that module, we could have a highly adaptable response team in each local community. [x] In addition, the new US solution must account for local training in the use of AM machines. As Deloitte explains, “by teaching AM technical skills to locals, and by supplying open-source software and part designs to enable them to continue to produce parts and products on-demand, [US Aid Orgs] can develop a local sustainable talent pool…which in turn encourages economic development.” [xi]

While AM does not solve the immediate need for food supplies or bottled water, it can replace much of our traditional, wasteful aid supply chain. My outstanding question is how can we make AM feasible and cost effective in areas without power or generators? Could Solar work, and if so, how costly might that be?

[Word Count 737]

[i]: Harvard Business Review, Anisya Thomas and Lynn Fritz, “Disaster Relief, Inc.” November 2006, https://hbr.org/2006/11/disaster-relief-inc, Accessed November 2018

[ii]: The New York Times, Frances Robles, “Containers of Hurricane Donations Found Rotting in a Puerto Rico Parking Lot”, August 2018, https://www.nytimes.com/2018/08/10/us/puerto-rico-aid.html, Accessed November 2018

[iii]: United Nations Office for Coordination of Humanitarian Affairs, “Shrinking the Supply Chain, Hyperlocal Manufacturing and 3D Printing in Humanitarian Response”, July 2015 https://www.unocha.org/sites/unocha/files/Shrinking%20the%20Supply%20Chain.pdf, Accessed November 2018

[iv]: Deloitte Review, Issue 19, Brenna Sniderman, Vikram Rajan, Parker Baum: “3D opportunity for life: Additive manufacturing takes humanitarian action”, July 2016 https://www2.deloitte.com/insights/us/en/deloitte-review/issue-19/3d-printing-for-humanitarian-action.html, Accessed November 2018

[v]: United Nations Office for Coordination of Humanitarian Affairs, “Shrinking the Supply Chain, Hyperlocal Manufacturing and 3D Printing in Humanitarian Response”, July 2015 https://www.unocha.org/sites/unocha/files/Shrinking%20the%20Supply%20Chain.pdf, Accessed November 2018

[vi]: Humanitarian Innovation Fund, Laura James: “Opportunities and challenges of distributed manufacturing for humanitarian response” https://docs.wixstatic.com/ugd/4bcea0_044a33fccd7043bea3ae25b9a5e0c198.pdf (pg.4), Accessed November 2018

[vii]: United Nations Office for Coordination of Humanitarian Affairs, “Shrinking the Supply Chain, Hyperlocal Manufacturing and 3D Printing in Humanitarian Response”, July 2015 https://www.unocha.org/sites/unocha/files/Shrinking%20the%20Supply%20Chain.pdf (pg.11), Accessed November 2018

[viii]: NBC News, Nicole Acevido: “Most federal contracts for Puerto Rico recovery go to U.S.-based, not local companies” September 2018 https://www.nbcnews.com/storyline/puerto-rico-crisis/most-federal-contracts-puerto-rico-recovery-go-u-s-based-n913401, Accessed November 2018

[ix]: Field Ready, “Shortcutting Supply Chains For Humanitarian Relief” https://docs.wixstatic.com/ugd/84d105_04cb064461754e05a038c53429aad807.pdf, Accessed November 2018

[x]: NCBI, Ingrassia PL et al. : “Education and training initiatives for crisis management in the European Union: a web-based analysis of available programs” March, 2014 https://www.ncbi.nlm.nih.gov/pubmed/24642198, Accessed November 2018

[xi]: Deloitte Review, Issue 19, Brenna Sniderman, Vikram Rajan, Parker Baum: “3D opportunity for life: Additive manufacturing takes humanitarian action”, July 2016 https://www2.deloitte.com/insights/us/en/deloitte-review/issue-19/3d-printing-for-humanitarian-action.html, Accessed November 2018

I think this is a great take on the potential for this technology to re-define how we approach disaster relief. I believe that to succeed, we have to consider the incentives and how we might make the government seek out these next gen solutions. Perhaps we could think about developing and proposing metrics around the success of disaster relief, against which the 3D printing technology would outperform the older ways of doing things.

This is an extremely interesting topic. I was excited to see that 3D printing is being applied to humanitarian crisis. I believe the power constraint could be mitigated through solar and/or utilization of local power generators. Many areas with unreliable central grids have businesses or homes that have gas powered generators. In the event of a national emergency these can likely be used to power the augmented manufacturing equipment. My main concern is how long a 3D printer would be useful in these contexts. In the first day or so after a disaster it doesn’t seem that it would be possible to setup a 3D printer with the shipping and training required. Likewise, after the first or second week, when some normalcy should be restored to the impacted area, I would question if a 3D printer would still be useful during long-term recovery. That leaves only a short window where I can see a deployed 3D printer having an outsized impact.

Very interesting topic, as we see time and time again that the responses to disasters fall short, despite large sums of money donated or allocated to alleviating the problems. Even if AM produces only incremental changes and improvements to speed the delivery of essential parts where they are needed, that will free up resources and space for essentials like food and water. You are wise to point out that capabilities like power are often limiting factors for this type of innovation. Still, I think there remains a role for AM resources to be positioned in close proximity to areas in need for the initial surge of aid, reducing transit and response times overall. I think that as AM capabilities advance, those interested in AM’s applicability to humanitarian uses should push for advances related to reduced or alternative sources of power consumption.

This seems like an incredibly smart way to ensure that aid dollars are being used efficiently. It also seems like a more sustainable solution than our current aid process – supplies could be printed only as needed, so that they aren’t wasted. Furthermore, as you note, locals could be trained to operate the machines, cutting out much of the wasteful overhead associated with our current development aid system. I imagine that as batteries and other ways of storing energy get smaller and cheaper, powering these machines in remote locations will get more cost-effective.

This is an incredible use case of additive manufacturing and I believe this can truly be a game changer in terms of administering humanitarian aid. I think your question is extremely valid – how can we make additive manufacturing cost-effective in areas that are already devastated by natural disasters. My first thought was that the additive manufacturing machines need not be situated in such commonly-devastated-areas since there is a distinct possibility that such machines may be destroyed during the disasters. Instead, these machines can be located within cities which 1) are relatively well-developed so that there will be sufficient electricity to power the machines and 2) have relatively lower risk of being hit by natural disasters. In this way, even though we still have a “last-mile” delivery challenge from manufacturing city to disaster city, it is at least within the same country and will significantly shorten delivery times.

This is an incredible and thoughtful use of additive manufacturing – and a well done piece! I am confident in solar energy to ensure sustainability and a power source. I really enjoyed your emphasis on economic stability and investment in the local communities. I believe this has been missing from both the narrative and the strategy of developed countries providing disaster relief for the last 2 decades. To your question, and as great as an idea as this may be, I fear for it’s viability. That is rooted in questions of access to the technology, and the immediate needs during disaster relief. On the latter point, from my experience, immediate needs (which would presumably be those filled by this fast acting 3D printing) are items which would could NOT be printed through this technology. As you mentioned, these items include food, water, diapers, medicine etc. However, I do not believe this makes the technology obsolete. I would simply argue that it is more applicable in the 5-10 days after a disaster strikes. On the first and more important point, given that disaster relief is often political, and often strikes countries with lower socioeconomic populations, I worry the presentation of 3D printers is altruistic, due to both the lack of access printers, and inability to access, ship, and utilize these printers in disaster zones.

As reflected in a number of the comments made above, I think that this is a great topic and a well-written article! I think that disaster relief is an area with a huge potential for positive impact. The need for localized response and streamlined logistics that you identify line up very nicely with the value proposition that 3D printing can provide. It seems that one of the biggest barriers here would be ensuring the availability of expertise when needed. It seems that if a database of data files for commonly needed goods was created, you would only need a small team to run the 3D printer(s) required to provide sufficient response.

This article has inspired me to look more into Field Ready and their plans moving forward – thank you for sharing!

The applications of Additive Manufacturing to aid and disaster relief is incredibly compelling, particularly given the areas you described around the inefficiencies surrounding supply chain, disbursement of charitable contributions, and sensitivities around timing. I wonder how feasible it is to use additive manufacturing during disaster relief given the high cost barriers, and how people are solving for that challenge through innovation and scale. The idea of finding more cost effective power sources through solar also is a great option, and hopefully more resources and work is devoted to this field moving forward.

Super compelling post, thank you for sharing your research and thoughts on this critical topic. Often, we hear about technology and automation as potential replacements for humans (including human labor, interaction, etc.) – at least, that is a long-term risk that is cited in popular discourse. What strikes me about Field Ready (and perhaps others like it) is that it is a technology company that is pairing innovative technology with local expertise and involvement. As the author notes, there are substantial opportunities to involve local people in training and implementation of 3D printing in disaster response. Further, during a published interview, Field Ready leader Andrew Lamb also articulates how involving, partnering with empowering people in these vulnerable and disaster-stricken locations is at the core of this technology company’s strategy. [1].

Taken together, it seems that organizations like Field Ready are effectively able to marry cutting edge technology (3D printing), a philanthropic and time-sensitive mission, and local community empowerment – a difficult to achieve, but extremely important, combination.

[1] Gahren, Isabel. “How 3D Printing is Revolutionizing Disaster Relief”

https://twentythirty.com/how-3d-printing-is-revolutionizing-disaster-relief/

This article was great!

As saddening as last year’s natural disaster in Puerto Rico was, it was more troubling/frustrating/infuriating to see how ineffective relief efforts were. More & more we see cases where aid is either too late, or does not fit the need at hand.

Deploying 3D-printing capabilities to underserved locations, could significantly relieve strain on supply chain operations when relief efforts are necessary. But as you allude to in your closing comments, I believe the new challenge is identifying how to effectively train individuals on this technology & solving how you would manage/operate/power these items in resource-constrained geographies.

Brilliant example and one completely new to me – thank you! You definitely have me convinced that this is a critical step forward in helping solve for the systemic inefficiencies in US disaster relief efforts. I do think that solar could work and that if 3D printers are deployed at scale, would have an appropriate price tag especially in the shadow of the large number of USDs that are typically wasted. My only concern would be around the machines needed to be extremely simple and efficient to use in disaster relief zones where, to put it simply, there is complete chaos. I still believe this application is worth investment and attention, especially as 3D printing becomes more sophisticated and will be able to create more complex and life-saving instruments.