3D-Bioprinting at Organovo: Effective testing now and maybe organ “printing” in the future?

Technology has come a long way in the field of medicine. Could it one day really be used to print entire, fully functional, human organs??

3D printing is the process of producing a 3-D physical object from a design created using computer aided design software (CAD). [1] 3D printing works on a principle called additive manufacturing, where each layer of the physical object is added one by one[2] ;each layer could be thought of as one part of a horizontal cross-section of the full structure.[3] In the medical biotechnology industry, 3D printing is used to develop tissue-like structures that could be used in a wide range of areas including evaluating the effect of drugs, developing organ replicas, and making implants and prosthetics.[4]

Organovo is the first company in the world to have developed and commercialized the 3D bioprinter. [5] 3D bioprinting helps (1) surgeons make critical decisions and (2) pharmaceutical companies test their new drugs quickly and more cheaply, allowing these companies to quickly cut off further investments in less promising drugs and invest more in promising drugs. [6]

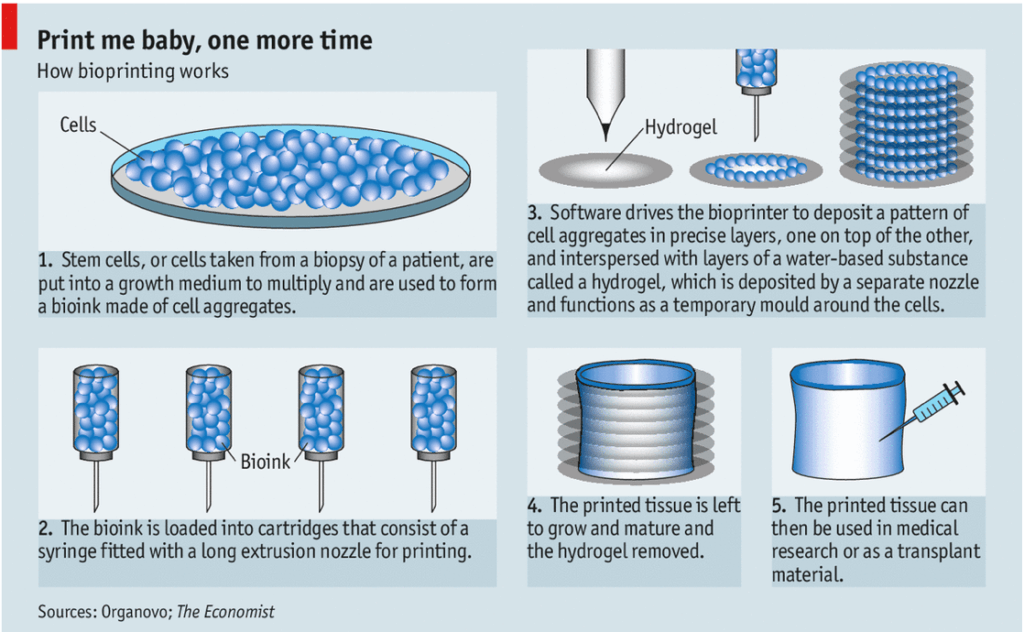

Organovo’s process can be summarized as follows:

- Identify the structure and makeup of the tissue of interest and develop a design using software.[7]

- Isolate the cells from the tissue and allow them to grow and multiply in a medium.[8]

- “Bio ink” is created through a unique process by combining cells from the previous step with building blocks.[9]

- The bio ink is inserted into this printer and software script is run to make the printer create the physical object layer by layer.[10] [11]

Exhibit 1 – Organovo’s step-by-step process (image and video)

3D bioprinting provides the following advantages over traditional processes:

- Customization – 3D bioprinters can produce highly customized replicas of human body parts such as organs, which surgeons can use to make critical decisions during surgery. [12] For example, in 2015, 3D printing allowed surgeons to successful perform open-heart surgery on a four-year-old girl. [13]The replica built through 3D printing enabled the surgeons to understand the specific complications of this girl’s heart and subsequently perform a successful surgery. In Orthopedics and hearing aids (99% of hearing aids are made using 3d printing), 3d bioprinting, with its’ focus on customization, is useful since one-size fits all implants don’t always match each patient’s unique characteristics.[14]

- Alternative to human/animal testing – Testing a new drug directly on humans/animals has drawbacks –- it is time consuming, expensive, and the side effects and efficacy are unknown. Organovo addresses these problems through 3d bioprinting. Organovo established a partnership with L’Oréal to 3D print living human skin cells. [15] This would allow L’Oréal to safely test for toxicity and efficacy of its skin-care products, without animal tests. Organovo also signed a deal with Merck to develop a 3D printed liver for toxicity testing. [16]

- Higher speed –3D printing takes considerably lesser time than conventional production processes, which necessitate extra steps such as milling and forging.[17] 3D printing is much quicker in making prototypes since it doesn’t require additional pre-production setup steps to make new prototypes; these steps will be required for traditional production methods. [18]

- Environmentally Friendly/ Lesser Wastage – 3D printing is an additive process and, thus, no excess material is used, only what is required for each layer is used. Thus there is minimal waste here, unlike subtractive manufacturing processes where there is wastage since the final product is shaped out from a larger initial product.[19]

I believe Organovo should do the following:

- Reduce costs: While 3D printing is more cost effective and faster for small production runs, for larger production runs, 3D printing does not maintain these advantages over traditional production processes. [20] [21] Organovo needs to find a way to profitably scale 3D printing. Only by producing larger volumes can it cover its high R&D costs.

- Modifying manufacturing processes to overcome structural weaknesses: Structures developed using the additive process in 3D printers may exhibit some amount of structural weaknesses compared to traditional processes.[22] For Healthcare purposes, safety is very important and since Organovo plans to develop structures to be inserted into humans in the future, it should adopt processes that increase structural strength.

- Increasing adoption: Some pharmaceutical companies are hesitant about the benefits of 3D printing and thus Organovo is taking longer to close these deals.[23] This delay combined with the company spending more and more on R&D has prevented it from being profitable, and the longer this continues, the more precarious its’ financial health will become. While Organovo has focused on pharmaceutical companies, it should also try to pitch its technology to more surgeons and hospitals in a bid to increase adoption and grow revenues.

Organovo has successful created 3D printed liver and kidney tissue cells. [24] The company hopes to develop 3D printed versions of entire organs in the future and could, thus, provide a boon to patients worldwide waiting for organ transplants. [25]

Could we one day really see 3D printed organs being put into human beings?

[Word count before references: 789]

References:

[1] http://www.economist.com/node/18114221

[2] http://additivemanufacturing.com/basics/

[3] http://3dprinting.com/what-is-3d-printing/

[4] Ventola, C. Lee. “Medical applications for 3D printing: current and projected uses.” Pharmacy and Therapeutics 39, no. 10 (2014): 704.

[5] http://www.invetech.com.au/portfolio/life-sciences/3d-bioprinter-world-first-print-human-tissue/

[6] http://seekingalpha.com/article/3095096-organovo-large-upside-potential-advantages-over-startup-competitors

[7] http://organovo.com/science-technology/bioprinting-process/

[8] https://3dprintingindustry.com/news/top-10-bioprinters-55699/

[9] IBID

[10] IBID

[11] http://organovo.com/science-technology/bioprinting-process/

[12] Ventola, C. Lee. “Medical applications for 3D printing: current and projected uses.” Pharmacy and Therapeutics 39, no. 10 (2014): 704.

[13] http://www.cnn.com/2015/10/06/health/3d-printed-heart-simulated-organs/

[14] Ventola, C. Lee. “Medical applications for 3D printing: current and projected uses.” Pharmacy and Therapeutics 39, no. 10 (2014): 704.

[15] http://www.bloomberg.com/news/articles/2015-05-18/l-oreal-s-plan-to-start-3d-printing-human-skin

[16] http://organovo.com/merck-bio-inks-deal-to-use-organovos-3d-printed-liver-for-preclinical-studies/

[17] Ventola, C. Lee. “Medical applications for 3D printing: current and projected uses.” Pharmacy and Therapeutics 39, no. 10 (2014): 704.

[18] https://www.marlinwire.com/blog/3d-printing-vs-traditional-manufacturing

[19] Campbell, Thomas, Christopher Williams, Olga Ivanova, and Banning Garrett. “Could 3D printing change the world.” Technologies, Potential, and Implications of Additive Manufacturing, Atlantic Council, Washington, DC(2011).

[20] http://www.forbes.com/sites/billconerly/2014/11/05/the-economics-of-3-d-printing-challenges/#494ef35a1bc8

[21] https://hbr.org/2015/06/the-limits-of-3d-printing

[22] http://www.paristechreview.com/2014/04/10/industrial-challenges-3d-printing/

[23] http://www.fool.com/investing/2016/09/12/how-risky-is-organovo-holdings-inc.aspx

[24] http://www.ibtimes.co.uk/organovo-ceo-3d-bioprinting-organs-will-help-us-get-people-off-transplant-waiting-lists-1509076

[25] IBID

Sources of Images/Videos:

Cover Image:

- http://3dprinting.com/wp-content/uploads/2013/07/Organovo.jpg

2.www.3ders.org/images2016/organovo-to-develop-transplantable-3d-bioprinted-human-liver-tissue-2.jpg]

Exhibit 1:

http://www.economist.com/news/technology-quarterly/21598322-bioprinting-building-living-tissue-3d-printer-becoming-new-business

https://www.youtube.com/watch?v=s3CiJ26YS_U->Video link

Organovo’s 3D printing business model is very promising. As you outline, there are many interesting applications of this technology in reconstructive and transplant medicine. One of the key challenges with transplanting a 3D printed synthetic organ into a patient has to do with infection risk. While Organovo has a sterile approach to making these 3D printed objects, they still remain largely artificial and will therefore increase the risk of infection by many folds. Perhaps antibiotics impregnated 3D printed organs will have to be incorporated in their models if the idea of a 3D printed organ is ever going to be a reality.

I found your article very interesting, and one the closest to achieving science fiction in real life, which I think is fascinating. This is a very promising technology that I think it’s potential should be reflected in their funding and stock price, therefore as it has been having some troubles to perform on expectations of their investors, the company must adjust its approach. Furthermore, it is unclear how they’re leveraging the digitalization trend we see nowadays to reach far more consumers and stakeholders. I agree on your recommendations for the next steps of the business but I would try a far more aggressive approach on adoption mainly because there’s such a high barrier, both based on scientific facts and risks, but also on biased fear of using new technologies that may potentially endanger human beings. This is solved by more robust processes, material applications, testing and public communication campaigns.