New Story: Remodeling Affordable Housing Through 3D Printing

New Story is tackling global homelessness and affordable housing with a 3D printed home that can be built in 24 hours for $4,000.

“Imagine if we could slash the cost and time it takes to build a home while improving quality and customization. This 3D home printer has that potential. Change is an open source pursuit so we are not building this technology for New Story, we are building it for the world.” – Alexandria Lafci, COO, New Story [1]

Introduction: Printing Your Pad

In March 2018, New Story, a San Francisco-based nonprofit focused on solving global homelessness through building resilient homes in developing countries unveiled its first 3D printed home, a 350 square foot structure in Austin, Texas. Built in partnership with ICON, a construction technology company specializing in 3D printers, New Story’s 3D printed home was built in under 48 hours and cost approximately $10,000. [2] Compare this with the ~$238,000 average cost and 4-6 month average construction timeline of an average home built in the United States [3], and it’s clear that New Story and ICON have tapped into a compelling opportunity to reshape affordable housing through harnessing the power of additive manufacturing.

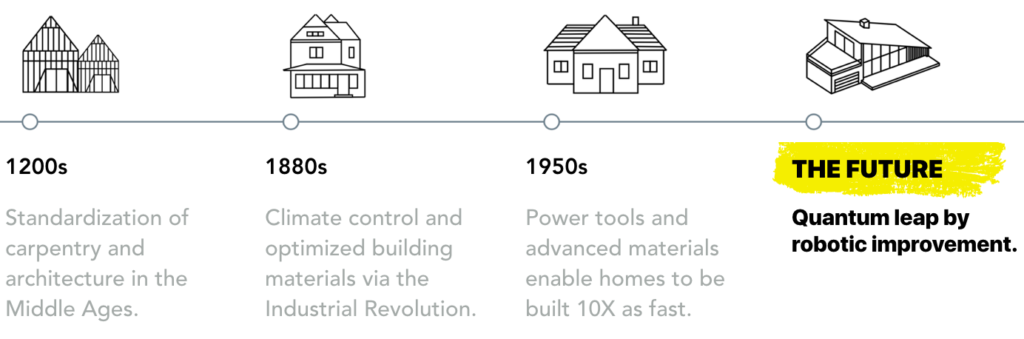

Simply put, additive manufacturing (or 3D printing), is an automated process of creating physical objects or structures through depositing materials in layers based on a digital file.[4] Seeking ways to increase productivity, quality, sustainability and safety while decreasing cost, waste and lead time for construction projects, builders have become increasingly interested in 3D technology to facilitate a more efficient construction process.[5] Technological advances, new start-up entrants, growing acceptance by established construction companies and government support have all led to momentum behind 3D printing in a traditionally conservative industry.[6]

Evolution of home-building technology. Source: New Story. https://medium.com/newstory/3d-home-printing-for-the-worlds-poor-e5be3f74b54d

Evolution of home-building technology. Source: New Story. https://medium.com/newstory/3d-home-printing-for-the-worlds-poor-e5be3f74b54d

New Story and Additive Manufacturing

According to the World Resource Institute, 1.2 billion people, or one third of urban dwellers globally, lack access to safe housing. [7] If current trends persist, 1.6 billion people could live without access to adequate and secure housing by 2025. [7] For New Story, an organization fighting global homelessness, additive manufacturing expands the company’s reach and impact exponentially, increasing output rate, quality and standardization.

Using current traditional construction methods, New Story requires 13-20 days to build a simple, sustainable home in a developing country at a unit cost of approximately $6,500. [8] Over the past four years, New Story has funded or built over 2,000 such homes in Mexico, Haiti, El Salvador and Bolivia.[8] Utilizing ICON’s 3D Printer, the Vulcan, a 2,000 pound robotic machine extruding precise one-inch layers of concrete based on uploaded software, the organization estimates it will decrease its construction timeline to 12-24 hours per home, at a cost of $4,000 with virtually no waste.[8] Through use of the Vulcan, New Story aims to deliver a 100-home community in as short as 3 months versus about a year through traditional construction.[9]

New Story’s 3D printed home in Austin, TX. Source: New Story. https://newstorycharity.org/3d-home/

In the short term, New Story’s objective is to transform from a niche project to a real-world affordable housing solution in countries that need it most. The organization plans to print its first 3D homes in El Salvador by the end of the year, and finish its first community by 2019. In order to achieve this goal, New Story and ICON are focused on confirming quality through seismic and safety tests, as well as iterating on Vulcan technology to decrease construction time from 48 hours to 24 hours. [2]

While many companies might want to retain this groundbreaking technology, New Story takes a different view. In the long term, New Story plans to democratize their technology, sharing innovative printing techniques with governments and organizations to expand the reach of the Vulcan and solve housing crises across the globe. [10]

Recommendations

Poised to create a paradigm shift in the world of affordable construction, New Story should take the time required to refine its design and technology to ensure the utmost quality and safety for its homes. While New Story stresses that quality in terms of thermal envelope and energy efficiency is higher than that of conventional stick buildings, many continue to question the quality of homes built entirely by software, and long-term durability remains unproven. Closing this perception gap will be critical for future mass adoption of the technology.

Despite growing popularity, 3D printed construction remains a niche market, with fewer than 40 large-scale projects fully realized around the world representing less than $100 million [6]. In the medium term, New Story should focus on scaling its construction through partnership with new countries and governments to garner further support. Expanding beyond a single design to more customizable home offerings will allow New Story to expand its reach, and expansion beyond single family homes to community centers, schools and public restrooms would allow New Story to build lasting environments. While the current technology produces the outer shell of a home, New Story could extend its technology to print interior furniture and infrastructure for utilities.

Questions

Will New Story and ICON 3D printed homes be capable of moving past a “niche” product into a mainstream affordable housing solution? How do we grapple with 3D printing eclipsing local job opportunities in homebuilding in developing countries? Beyond affordable housing, is 3D printing better suited for constructing small components versus a home in its entirety?

(792 words)

Sources

[1] News Story. “New Story Press Kit,” https://newstorycharity.org/press-kit/, accessed November 2018.

[2] Aria Bendix. “These 3D-printed homes can be built for less than $4,000 in just 24 hours.” Business Insider, September 25, 2018, [https://www.businessinsider.com/3d-homes-that-take-24-hours-and-less-than-4000-to-print-2018-9], accessed November 2018.

[3] Carmel Ford. “Cost of Constructing a Home.” National Association of Home Builders Economics and Housing Policy Group, December 1, 2017, [http://www.nahbclassic.org/generic.aspx?genericContentID=260013], accessed November 2018.

[4] Dennis Spaeth. “3D Printing is changing the face of multiple industries.” ECN: Electric Component News 61, no 9 (October 2017): 21-23.

[5] Mehmet Sakin and Yusuf Caner Kiroglu. “3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM.” Energy Procedia 124 (2017) 702-711, via ScienceDirect, [https://www.sciencedirect.com/science/article/pii/S1876610217346969], accessed November 2018.

[6] Romain de Laubier , Marius Wunder , Sven Witthöft , and Christoph Rothballer. “Will 3D Printing Remodel the Construction Industry?” Boston Consulting Group, January 23, 2018, [https://www.bcg.com/en-us/publications/2018/will-3d-printing-remodel-construction-industry.aspx], accessed November 2018.

[7] Robin King. “The Crisis in Affordable Housing Is a Problem for Cities Everywhere.” World Resource Institute, October 2, 2017, [https://www.wri.org/blog/2017/10/crisis-affordable-housing-problem-cities-everywhere], accessed November 2018.

[8] Adele Peters. “This House Can Be 3D Printed For $4,000.” Fast Company, March 12, 2018, [https://www.fastcompany.com/40538464/this-house-can-be-3d-printed-for-4000], accessed November 2018.

[9] CNBC. “New Story is a NonProfit That Uses 3-D Printer to Build Homes in Poor Communities,” YouTube, published March 15, 2018, [https://www.youtube.com/watch?v=wRr3R3IKbuU], accessed November 2018.

[10] Carly Olson. “New Story Unveils First 3D Printed Home.” Architectural Digest, March 12, 2018, [https://www.architecturaldigest.com/story/new-story-unveils-first-3-d-printed-home], accessed November 2018.

This is an interesting topic and a well written essay. I’d be curious to know about the changes of building/transporting The Vulcan as well. From my personal point of view, I think it’s great to use this technology if New Story can make it widely available, but even if they can get it to a point where it’s cost effective, I wonder how widely they’ll be able to spread it.

Their approach to democratizing this technology is very interesting as well. It will be interesting to see if any competitors come up in this space and what that does for the overall effort.

Really great piece – thank you for sharing. Like Mike notes above, I’d be very intrigued to see how scalable the roll-out of Vulcan is globally to developing markets, and how ICON considers its work with New Story relative to their other “clients.” Given that AM technology is already on the expensive side (and I’d imagine that, given the sheer size of the technology required to build a house, is even more expense in the case of Vulcan), I’m curious how New Story will be able to secure the funding required by Vulcan to bring this to the markets where it is needed most. Which government agencies or NGOs might be willing to work with both New Story and ICON to make this a more accessible technology? As you note, AM might have adverse effects on the labor markets in these developing areas where affordable housing is most in demand. Would this prevent New Story and ICON from finding the partners they need to bring this to life as well?

Great topic, in addition to the affordable housing market, it will be interesting to see if this has legs in the traditional market or in areas where getting traditional raw materials is hard. This has the potential to provide housing for millions of people who currently have to go without but as Jake mentioned above there could be powerful interests that don’t want this to come creating a tension.

Some cities are promoting policies that encourage people to build affordable housing units in their backyards (i.e, Los Angeles is even piloting a program that would pay people to build smaller backyard homes to house homeless individuals: http://www.latimes.com/local/lanow/la-me-ln-homeless-tiny-house-20180411-story.html). I wonder if this project could begin combatting NIMBY (‘not in my backyard’) issues that permeate the homelessness and affordable housing debates in many U.S. cities by partnering with them on similar projects.

This is a really interesting topic – thanks for sharing. Thinking of other applications for this technology, temporary shelters for displaced individuals from natural disasters also comes to mind. As you point out, I think there is a long way to go in convincing consumers that this product is high-quality and safe, but this is an achievable goal. Regarding one of your questions, I think New Story should focus on both small components and full sized homes and they could do so without cannibalizing sales for either. There’s tremendous market potential for both and as a first mover, I think they’ll have a lot of opportunity for social impact and growth.

Great read. I do agree with your points and some of the points of other commenters that there will be significant perception issues to overcome and safety concerns to disprove before printed homes move to main stream from niche. Regarding your question around concern for displacing local jobs in the housing market, I think there is critical mass to be gained before that is a real threat. In some developing areas that I have visited, the ability to reduce homelessness outweighs the little money the workers in the construction business are paid, many of whom may be homeless themselves. I think its a great opportunity.

This is so cool! Such an innovative idea and for a good cause. Some of the previous comments have touched on this, but I was also wondering how this scales. Does the printer have to be on site? Or do they print pieces that they transport and then assemble? If so, it’s surprising (but awesome) that it is so significantly cheaper than traditional building.

I personally would not be overlay concerned with taking over construction jobs just yet. These projects are still relatively niche, and though they will hopefully grow with time, it will likely take a while before this becomes mainstream and we switch to this for large scale construction, so the industry workers will likely have a lot of time to get up to speed with the technology. There is also likely a steep initial investment needed to buy the machinery, so I imagine it will be tough for construction companies to afford, and 3D printing will, at least in the meantime, be reserved to these types of projects.

This reminds me of the mission of the organization “Little Home” in cities across Germany, they however build smaller homes, and they do not 3D print them.

I agree with the need to ensure quality and durability. But for the “…one third of urban dwellers globally, lack access to safe housing” I believe creating more of these houses and improving quality over time would be more impactful.

In addition, I think the point on 3D printing of smaller items, such as furniture, can be a potential revenue driver to enable this organization to continue operating and to bring more housing to more people in need.

Super interesting insights and information. One thing I would be skeptical about is that this technological leap in terms of 3D printing is presented as a solution for the world’s homeless population. Much like increased food production promised the end of malnutrition, distribution and willingness of governments seem to be the largest impediment to providing every person with shelter. Thus, does driving costs down alone actually lead to more home ownership or less homelessness? Moreover, is their a potential misuse of this type of technology and could it potentially concentrate wealth in the hands of a very few who can purchase this technology while doing away with large amounts of laborers?