Lots of Chocolate for Me to Eat

The debate is about whether additive manufacturing will disrupt the way chocolates are manufactured.

Chocolate is a universally delectable food. 3D printing could potentially disrupt the industry (worth $ 50 billion globally), pushing it towards mass customization among the 6 emerging business models in additive manufacturing. (mass customization, mass variety, mass segmentation, mass modularization, mass complexity and mass standardization) [1]. Large chocolate manufacturers like Hershey’s are exploring the potential changes that it may cause to the industry.

Megatrend and Process Improvement

3D printing will allow large American chocolate manufacturers, like Hershey’s to offer custom products to their clients at a much lower price compared to the past. Hershey’s has been losing market share to premium Belgian and Dutch chocolate manufacturers. A 3D printer will allow the company to print each country’s chocolate in a cost-effective manner and in this way, prevent foreign competitors from entering the market. In addition, it provides a tailored product to the end user, allowing them to pre-select or create chocolate designs of their own. The company could also consider distributed manufacturing with the ability for mass-scale 3-D printing in areas without Hershey manufacturing facilities. A final option for the company would be to leverage 3D printing for the adoption of non-chocolate 3-D food printing [2].

Hershey’s Strategy in Short and Medium Term

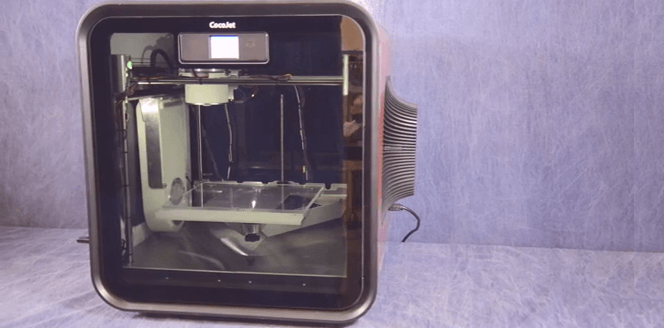

Hershey’s and 3D systems (3D systems is a company that engineers, manufactures and sells 3D printers. The company creates, concept models, and prototypes for digital manufacturing) collaborated to create a “Cocojet 3D printer” [3]. Additive manufacturing for edible industries comprises of two main technologies, namely, direct printing or mold printing. The printer developed by Hershey’s builds chocolates layer by layer, using the process of directing printing. This printer can do anything that a regular 3D printer can do with plastic. The printer can build intricate design, all with sweet chocolate. Direct printing uses the extrusion principle, which allows high degrees of freedom, since the design does not have to be removed from a mold. Since no mold is required, costs are limited to the digital design of the object, machine’s amortized cost and the chocolate-based input [4]. Customized chocolate, using technologies like above, is available at global Hershey’s locations. The company also installed the printer at the Culinary school to see how different chocolate shapes could be produced, which are generally not possible under normal molding techniques.

In the medium term, Hershey’s hope is that chocolate printers become easy to use, such that it can sell them to restaurants and bakeries. In this way Hershey’s could also enter a new business line of selling printers, in addition to chocolate. This would help in blocking rivals that might try to enter the American market through those channels.

Technological Barriers and Food for Thought

3D printing of chocolate, still has some technological barriers which would need more attention. The process is temperature sensitive and because of this can be time consuming. The “Cocojet” machine throughput time can vary depending on the design, from 33 minutes, all the way to 1 hour and 26 minutes. Another issue is that, the chocolate must be warm enough to melt, but the bottom part must be cool enough for object to hold its shape. There are limited designs you can make structurally with chocolate, as compared to other materials. e.g. plastic.

In the short term, chocolate manufacturers need to embrace the technology whole-heartedly and understand that this technology is a powerful tool for them to leverage efficiently. It will help them provide better results to their customers. More research should be undertaken in this field such that with each iteration, the technology will become faster and more precise. Depending on the design, throughput times can be reduced. They could also avail of the research and development tax credit, which ranges from 4-7%, if research is for new and improved products and processes. Earlier it could take weeks before manufacturers got a molded bar of chocolate to consumer testing, now this process can happen overnight with 3D printing [5].

In the medium term, Hershey’s should also take inputs from customers, by running pilot tests in public and accordingly continuously optimize the process of chocolate 3D printing. The company should also leverage the accuracy that can be obtained with 3D printing and the fact that products can be highly customized for special occasions (e.g. wedding days or birthdays).

Future Work

In the context of additive manufacturing and the chocolate industry, the debate is whether, the 3D printing, will be useful for a niche product, or if it will be useful mass production in areas where there are no manufacturing facilities. Will this be a revolutionary change to the way chocolate is manufactured or is this simply a tool for better customization?

(768 words)

Cocojet 3D Printer [6]

3D Printed Chocolate [7]

REFERENCES

[1] https://hbr.org/2018/07/the-3-d-printing-playbook. Visited on 11th November 2018

[2] https://adage.com/article/news/edible-3-d-food-printing-a-reality-hershey/296812/. Visited 13th November 2018

[3] https://www.entrepreneur.com/article/241596. Visited on 10th November 2018

[4] https://www2.deloitte.com/insights/us/en/focus/3d-opportunity/3d-printing-in-the-food-industry.html. Visited on 11th November, 2018

[5] https://3dprint.com/213896/rd-3d-printing-chocolate/. Visited 12th November 2018

[6] https://3dprint.com/35081/culinary-printing-3d-systems/ Visited on 12th November 2018

[7] https://www.google.com/search?q=3D+printed+Chocolate&source=lnms&tbm=isch&sa=X&ved=0ahUKEwislJmTls3eAhWQMd8KHSOLCKwQ_AUIFCgC&biw=1517&bih=730#imgrc=JuX1Dm6ZXB3gbM: Visited 12th November 2018

This essay was truly engaging, as it touched on a topic I had not previously considered – how 3D printing could impact the food and beverage industry. I found the arguments on the customization benefits extremely insightful, specifically the notion that “customized chocolate, using technologies like above, is available at global Hershey’s locations.” My only concern with the thesis of this piece is the rate of adoption. While 3D printing will clearly benefit Hershey’s from a manufacturing standpoint, how will consumers respond? From working paper articles including “I Can’t Get Past the Fact That It Is Printed: Consumer Attitudes to 3D Printed Food” (https://www.researchgate.net/profile/Deborah_Lupton/publication/311576615_%27I_Can%27t_Get_Past_the_Fact_That_It_Is_Printed%27_Consumer_Attitudes_to_3D_Printed_Food/links/584e753708ae4bc89936b46d/I-Cant-Get-Past-the-Fact-That-It-Is-Printed-Consumer-Attitudes-to-3D-Printed-Food.pdf) it is evident that some consumers are skeptical. Given this, I am cautious that 3D printed chocolate will not become mainstream in the short or medium term. However, as a whole, I agree with the author’s argument that 3D printing has the ability to truly transform the industry, specifically on a cost and production front.

This was an absolutely fun read and evoked ‘Willy Wonka’ memories to even imagine a world where chocolate can be forced to bend to our wills. I completely agree with the argument that customer-designed 3D-printed chocolate will be an instant crowd-pleaser. As I think more on this however, the following major concerns cross my mind:

1. What is the real differentiator here for Hershey’s? Is it the customized chocolate or the feeling of exclusivity that a customer gets on obtaining it?

2. To build off of Q1 above, if the differentiator is the customized chocolate, then is it really that much of a barrier to entry to deter other, ‘premium’ players from jumping on to the 3D printing bandwagon?

3. Ultimately, consumers will return to your brand for certain functional and associated benefits (think premium ingredients, brand value etc.) – is the 3D printing gimic really sustainable, not just in this case, but in the food industry in general, given that it isn’t solving for any inherent issues except boosting market perception temporarily at the cost of a more complex logistics network?

Absolute delight reading this article and it definitely provided a view of how additive manufacturing is permeating many industries, including F&B and the world of chocolate! I thought it was interesting that you mentioned how this could be a real advantage for Hershey, and explored how they could build on this trend. While the question poised was whether 3D printing could benefit them through sale of niche or mass product, I wonder if this disruption could go as far as to take market share from them, ultimately leading to a net-negative impact. In my mind, there could be two scenarios, one where technology mature and allow for mass production, and the other where technology remains nascent within F&B and would be biased towards niche product. If the former happens, it would be hard for Hershey to leverage it for massive upside since production would be limited. Whereas if the latter happens, many new entrants might come in to produce chocolate and saturate the market. I can even imagine vertical integration happening, and Hershey loses the competitive advantage that they had. This dichotomy might seem a little extreme, but I thought it would be interesting to push this hypothesis as an additional food for thought.

What an amazing essay! While I am one of the only ones who doesn’t like the taste of chocolate (crazy!), I was excited about the number of ways 3D printing could be used in the food industry.

For Hershey’s, I do see 3D printing as a niche opportunity. I was reminded right away of what Dylan’s Candy Bar is doing with 3D printing (source below). Dylan’s has positioned 3D candy as a customized, exclusive product. I think Hershey’s could have a 3D candy station at their worldwide store locations and available as customized orders online. Similar to how Dylan’s operates in their store locations, there could be a Hershey’s 3D printer station. This experiential product will draw customers in and generate buzz about the product. Hershey’s could charge a higher price for customized 3D chocolate, because customers will have a higher value proposition for this customized order.

Source: https://www.chicagotribune.com/dining/ct-3d-printer-gummy-candy-dylans-story.html

Fascinating read on a product that is very common to all of us.

From a competition standpoint, I was curious as with some others who posted here about how much of Hershey’s and 3D systems work will help them remain competitive. Do we have any idea as to the content of their contracts/patents? It does seem like a good match of companies here, Hershey’s with traditional chocolate production know-how and 3D systems with the operation know-how of 3D printing. At the same time, I wondered how much of this could be replicated by its competitors, and if so, in what time frame.

I also felt the potential of this technology in high-end market of foods, like cake and gourmet restaurants. It would be fascinating to see what companies like 3D systems can do and how they could have an impact on entire gastronomy community in the future.