Cool Power: A Paradigm Shift?

Liquid Nitrogen: Creating cool environments with cold power

In 1902 a young company presented Liquid Air, an automobile that was to be fueled by liquid nitrogen. Unfortunately, the principals were unable to take this concept past design phase, going into receivership. Ever since, certain engineers and scientists have concerned themselves with the question: can liquid nitrogen be used to power an engine. Nearly a century later a British inventor, Peter Dearman, succeeded where those before had failed. His Dearman Engine successfully runs his car using liquid nitrogen, though the lack of gas stations providing such a fuel in the UK, means that he can’t take it too far. [1]

From this innovation, Dearman formed a company, which is now 50 people strong, has raised close to $25m in the last year, with one of the largest supermarkets in the UK (Sainsbury’s) trialing the Dearman technology on their refrigerated trucks. [2] Dearman’s CEO, Toby Peters, claims that the technology can become a central aspect of what he calls the emerging ‘cold economy’. [3] This technological breakthrough is particularly relevant when you consider that heat driven engines (and therefore heat emitting) are the primary mechanism used to cool environments such as cold chains, and that the warmer the context the more power is required to cool any given space.

Given that food wastage is the third largest CO2 contributor (after the US and China), and given the growth of cold chain is going to happen in warmer and warmer environments (i.e. emerging markets), clearly new ways of creating ‘cold’ should be found. [4] Given that Dearman system is projected to attain a 50% efficiency saving when compared to diesel run cold systems, this appears to be one additional option. This is particularly interesting from an environmental perspective given its only emission is nitrogen, which already makes up 78% of the atmosphere.

The Technology

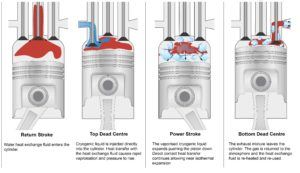

The engine at the heart of the technological process is a normal piston engine which has been around for generations. However, where the combustion engine uses lit fuel as the mechanism for driving the pistons, the Dearman Engine starts at the other end of the spectrum using liquid nitrogen, which has a boiling point of -196°C. What was particularly innovative about the Dearman product is its division of the inputs into two. See the below graphic for Dearman’s explanation of how the engine works:

Figure 1: Graphic Illustration of Dearman Engine [5]

Infrastructure & Cost Challenges

As the Dearman team take this technology through trial stages there are a couple of factors that are against the group. Primarily the infrastructure required to service a liquid nitrogen engine. The availability of liquid nitrogen, and the safe handling of it remains a large constraint to the delivery of this invention for mass market consumption. A compelling case can be made that businesses already using liquid nitrogen, and indeed businesses with proximity to LNG liquefaction plants (where liquid nitrogen is used as part of the cooling process, but then evaporated on delivery), could tap into this fuel source with greater ease than others. Therefore, it is reasonable to assume that the initial market for this product will be commercial buyers, such as those businesses operating cold chains.

Another significant question mark with respect to this business is the price point of the technology, and the ongoing cost of running it. Dearman are yet to provide insight into this issue – but for this technology to be successful, the lifetime cost of a Dearman engine must be below that of its diesel counterpart.

The Opportunity

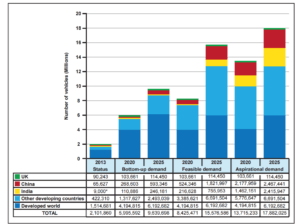

What is perhaps most exciting about this company in the context of a climate sensitive world, with growing middle class consumption is the rise of the emerging market cold chains. Chinese fruit and vegetable wastage is estimated at $20 billion per annum, with 5% transported within a cold chain. In India it is estimated $13b billion is wasted. [6] The below graphs the estimated growth in cold trucks over the coming years. Should Dearman be able to provide a cost comparative solution, that has the endorsement of a large UK supermarket chain such as Sainsbury’s, the company will be very well placed to tap into the massive growth potential in cold chains across emerging markets.

Figure 2: World Refrigerated Vehicle Fleet Growth Rates [6]

Conclusion

Addressing food wastage and engaging with the increasing need to introduce cool environments globally, in an emissions conscious way, will be of paramount importance in the coming decades. Should Dearman come through their development stage, and complete a successful trial with Sainsbury’s and others, the company will be very well placed to tap into the exponential growth of the cold economy across emerging markets in the coming decade.

[Word Count 776]

[1] “Cool thinking: An inventor’s persistence may be about to pay off,” The Economist, May 9th 2015, http://www.economist.com/news/science-and-technology/21650517-inventors-persistence-may-be-about-pay-cool-thinking , accessed November 2016

[2] “Sainsbury’s is world’s first to trial truck cooled by liquid nitrogen engine,” Dearman, 2016, http://dearman.co.uk/sainsburys-is-worlds-first-to-trial-truck-cooled-by-liquid-nitrogen-engine/, accessed November 2016

[3] Toby Peters, “The Cold Economy – Why? What? How?” University of Birmingham, May 2016, http://www.birmingham.ac.uk/Documents/college-eps/energy/Cold-Economy.pdf , accessed November 2016

[4] “Food wastage footprint: Impacts on Natural Resources – Summary Report,” FAO, 2013, http://www.fao.org/docrep/018/i3347e/i3347e.pdf , accessed November 2016

[5] “The Dearman Engine,” Dearman, 2016, http://dearman.co.uk/dearman-technologies/the-dearman-engine/ , accessed November 2016

[6] “Cold Chains and the Demographic Dividend,” Dearman, 2015

This is amazing – but I wonder why they’ve decided to make their first application transportation / businesses with cold chains, given the lack of LNG infrastructure and the complexity of maintenance (they’d have to be able to do roadside maintenance if first applications are trucks – which is much more difficult than stationary applications.)

Why wouldn’t they start with high energy-use businesses that also have high cooling costs, like data centers?

I’m amazed! The idea is very much revolutionary for the cold chain business and beyond. Since handling liquid nitrogen requires massive training and infrastructure, it’ll be very interesting to know more about what partnerships they will end up doing in realizing their services, or how much of those will be integrated to the core business as well (Tesla?). I’d imagine this would also impact where their target market is, and how limited they are to expanding to unsupported regions, such as in emerging countries.

Great Article and a very interesting approach. I did not even consider food waste when thinking about climate change. This is a very interesting technology and you outlined a lot of the challenges around the maintenance, cost, and infrastructure challenges with using liquid nitrogen. With that context it was surprising to me that they are focusing on the distribution of cold-channels. Particularly because the cooling process requires a lot of energy and liquid nitrogen has significantly lower stored energy the diesel fuel. Did you find any insight into the amount of liquid nitrogen required to achieve the same cooling effect as 1 gal of fuel? Given the infrastructure challenges that exist this seems like a potentially limiting factor in scaling this technology.

Great post! I love learning about these new takes on the internal combustion engine and the synergies this company proposes by partnering with cold-channel distribution and utilizing liquid nitrogen “waste” from CNG liquefaction. However, I have two questions:

1) One of the core tenants of the Dearman engine is the use of a warm heat exchange fluid to cause flash evaporation of liquid nitrogen during the power stroke. In Figure 1 this heat exchange fluid is then “separated and re-heated” for reuse within the system. What is the source of heat Dearman proposes to use to re-heat this fluid? I assume he is proposing a heat exchanger using ambient warm air as the most cost effective and environmentally conscious solution, but I am concerned that the size that these heat exchangers will need to be to accomplish a meaningful heat transfer rate.

2) What is the net carbon balance on the Dearman engine when the energy needed to separate and condense nitrogen and the energy consumed transporting liquid nitrogen from CNG plants to distribution centers (like Sainbury’s) is considered? I understand the concept of using liquid nitrogen from CNG plants since it is effectively “waste,” but knowing how energy-intensive and inefficient nitrogen liquefaction is I have serious doubts that the entire energy cycle will even be close to being carbon neutral.

Hi N! Thanks for sharing Dearman’s innovation with us. I have to admit I remain a bit of a skeptic! My worry is about the other costs in this eco-system. In my past experience, I have found that often, improved technologies create more problems than they solve when including the externalities associated with them. The application to this circumstance would be to include the carbon and energy footprint of the entire value chain in the calculation, rather than just the emissions of the engine. Specifically I am wondering if all the costs of collecting, pressurizing, cooling, transporting and storing liquid Nitrogen are so severe that they undermine the zero-emission engine.

Happy to discuss more on twitter — find me @jzaslav 🙂

Thanks for sharing information on this technology N. Food wastage is definitely a huge cost in countries like India with very limited cold storage facilities and in fact is currently an area where lot of investment interest is being generated. I could see how cold storage units can perhaps directly use liquid nitrogen energy but I am not very sure why cold storage would be of particular interest as use of cold nitrogen ENGINE technology.

And related to cold nitrogen engine, I share the same concern on net carbon footprint of this technology and the scalability of the same. It will be great if you could share some insight on this. Thanks.