Walmart: Using machine learning to reduce food waste

Food waste is a major problem across the globe. Grocery retailers incur significant costs from this wastage, particularly in the produce category. Walmart is taking this problem head-on with analytics using ‘Eden’: a machine learning algorithm that screens produce for quality and freshness. This post explores Walmart's attempts to improve their food waste process with Eden.

You may find it surprising that 30% of global food production is wasted annually. This is a serious problem – if food waste were a country, it would be the third-largest greenhouse gas emitter.[1] Grocery retailers (“grocers”) are in a unique position to address this issue. It’s estimated that food waste reduction represents an $18.2B opportunity for US grocers.[2]

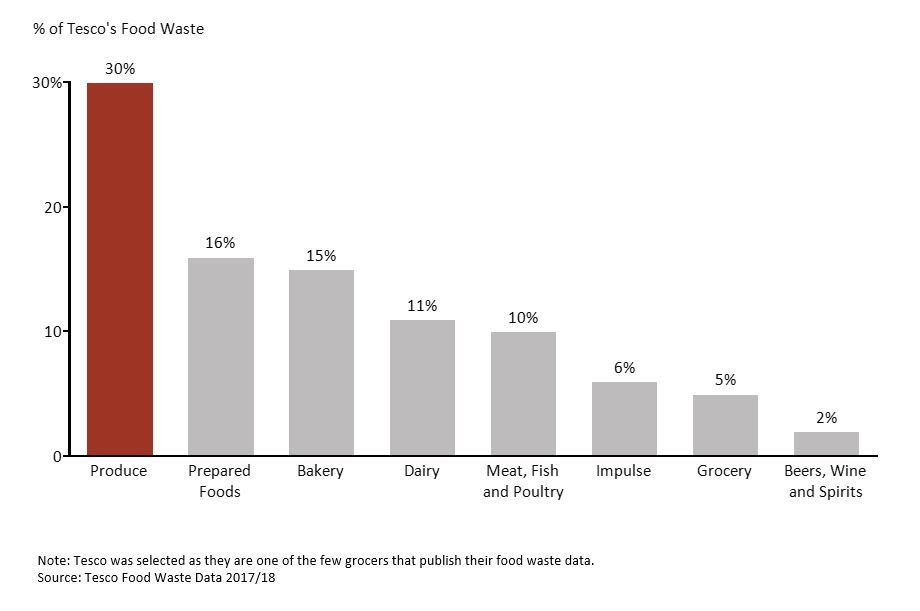

Fresh produce makes up a significant proportion of this wastage. For Tesco, the UK’s market leader, 30% of its food wastage comes from produce (see Figure #1). But changing behavior is difficult – produce is a ‘halo category’, which attracts customers into store and converts them into other categories. Grocers have an incentive to only display aesthetically-pleasing produce and discard the remainder.

Figure #1-Wastage by Category[3]

Walmart: Addressing Produce Waste

In the past, Walmart used manual inspections to assess the quality of produce shipments based on in-person review and photos. After these inspections, produce would be accepted/rejected, per USDA guidelines.

Recognizing this inefficiency, Walmart held an internal hackathon event in 2017 – the result was ‘Eden’, a machine learning algorithm that scans produce to assess quality and freshness. With Eden, Walmart digitized the USDA quality standards and trained its algorithms on the 1 million old produce photos they had stored. The availability of this data allowed Walmart to launch Eden 6 months after conception.[4]

Eden saved Walmart $86M, through reduced food waste, in the 6 months after launch. It projects additional savings of $2B over the next 5 years.[5]

How Does it Work?

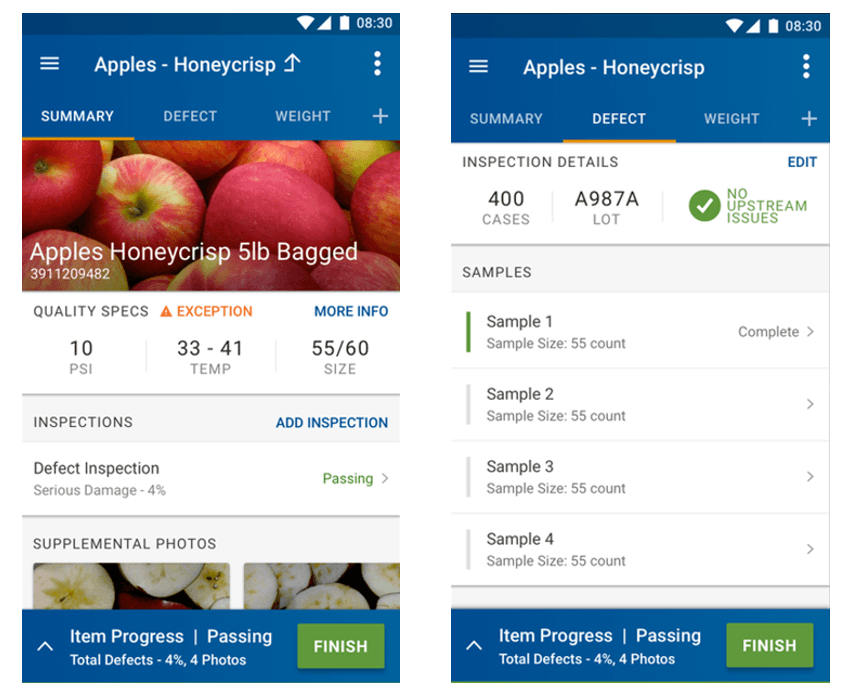

Eden has a suite of apps that allow workers and suppliers to take photos of shipments – which are assessed using Eden’s algorithms, providing real-time analytics on the defect rate, freshness level etc. (see Figure #2). This reduces screening time, resources wasted transporting defect produce and allows for in-store prioritization.[6] Walmart has also begun to add sensor data to Eden – generated by monitoring temperature/light conditions for each shipment.

Figure #2-Eden Interface

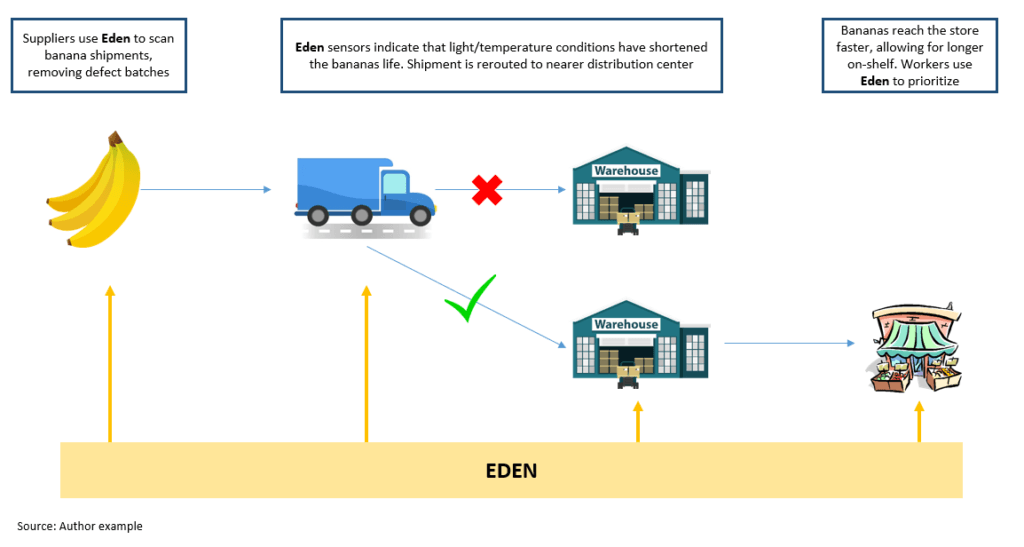

Take an example: per Figure #3, suppliers use Eden to detect defects before shipment. While en-route, sensors indicate conditions have altered the produce’s useful life – so the shipment is rerouted to a nearer distribution center. The produce then reaches the shelf faster – where workers can prioritize it as required (e.g., with price markdowns).[7]

Figure #3-Eden Use Case

Value Creation/Capture

Eden undoubtedly creates value by enhancing the experience of customers. It allows Walmart to closely monitor shipment quality and the freshness of produce – ensuring quality is maintained on-shelf for customers. It’s interesting to consider if customers’ advocacy increases because of the environmental benefits from reduced food waste. I believe this is the case for younger generations – in a recent survey, 45% of those below 44 said they consider food waste when grocery shopping vs. 27% for 45-64 year olds [8].

It’s clear that Eden provides significant economic benefit to Walmart – which is value that didn’t exist before. Walmart is jointly growing the ‘pie’ with its suppliers – i.e., creating value by helping them screen shipments. This assumes that the supplier cost saving from not shipping defective produce offsets the increased cost of disposal. However, it’s likely that Walmart will use its bargaining power to pressure suppliers to give up this created value (i.e., value capture).

Challenges

Walmart has not released any data on Eden’s screening effectiveness vs. humans – so we have to assume it’s superior. Walmart’s challenge will be to continuously improve Eden over time. However, it’s in a fortunate data position – it should leverage data from its international operations, making Eden more difficult to replicate.

Walmart may also face near-term controversy with Eden. Startup Zest Labs sued Walmart for $2B in 2018, alleging that it worked with Walmart on a similar product for many years before Eden. They claim their proprietary information was stolen to create Eden.[9] Walmart will likely settle and continue to operate Eden.

Conclusion/Opportunities

It’s clear that waste reduction analytics is highly valuable to Walmart. It has allowed them to utilize an under tapped resource: their produce data. It increases customer advocacy and allows Walmart to ‘grow the pie’ with suppliers.

What’s next? I would encourage Walmart to use Eden to refine grocery delivery – given inconsistent produce freshness is a major current barrier to adoption. They could pass-on Eden information to customers in advance– i.e., the expected life of their produce.

Finally, Eden undoubtedly results in an environmental benefit. Given this, should Walmart open-source the technology, making it widely available to other grocers? It would be in the best interests of the environment, but I doubt Walmart will.

(749 Words)

References

[1] Yale Climate Connections. May 2019. “Food waste starts long before food gets to your plate”. Retrieved from: https://www.yaleclimateconnections.org/2019/05/food-waste-has-crucial-climate-impacts/

[2] ReFed. Jan 2018. “ReFed analysis reveals food waste represents $18.2B profit opportunity for grocery retailers”. Retrieved from: https://www.refed.com/content-hub/refed-analysis-reveals-food-waste-represents-18-2-billion-profit-opportunity-for-grocery-retailers

[3] Statista. 2018. “Share of Tesco store food waste in the United Kingdom (UK) in 2017/18, by category breakdown”. Retrieved from: https://www.statista.com/statistics/490863/tesco-group-united-kingdom-uk-food-waste-by-category/

[4] Phil Lempert. Forbes. Mar 2018. “Walmart Wants To Sell The Freshest Produce, And It’s Using iPhones To Do It”. Retrieved from: https://www.forbes.com/sites/phillempert/2018/03/01/walmart-wants-to-sell-the-freshest-produce-and-are-using-iphones-to-do-it/#beb563593e4d

[5] Dan Alaimo. March 2018. “Walmart develops produce inspection technology to track freshness”. Retrieved from: https://www.grocerydive.com/news/grocery–walmart-develops-produce-inspection-technology-to-track-freshness/534221/

[6] Walmart. Mar 2018. “Eden: The Tech That’s Bringing Fresher Groceries to You”. Retrieved from: https://corporate.walmart.com/newsroom/innovation/20180301/eden-the-tech-thats-bringing-fresher-groceries-to-you

[7] ibid.

[8] New Hope Network. Sep 2019. “Survey finds younger consumers most concerned about wasting food”. Retrieved from: https://www.newhope.com/news/survey-finds-younger-consumers-most-concerned-about-wasting-food

[9] Ashley Nickle. Oct 2018. “Zest Labs lawsuit against Walmart set for trial in 2020”. Retrieved from: https://www.produceretailer.com/article/news-article/zest-labs-lawsuit-against-walmart-set-trial-2020

Colm, thank you for writing about this. Eden is truly fascinating. This is a great way of reducing food waste.

Does Eden individually screen grocery deliveries for freshness and longevity? I remember reading an article a while back about several customers falsely complaining to online grocers claiming their produce was damaged/rotten upon delivery to claim a refund. Perhaps your recommendation to pass on Eden information to customers could also serve as insurance against fraudulent claims

Also, does Eden falsely identify produce that is fresh but not aesthetically pleasing as “bad”? If this is the case, I wonder if this inadvertently leads to a waste of produce that is actually fresh, but no pleasing to the eye. There is a rise in companies selling ugly produce. One that comes to mind is “The Wonky Food Company”.

On your first point: I don’t believe Walmart is using Eden for anything related to direct-to-consumer grocery deliveries yet. Interesting point around the fraud reduction – I would how big a problem that is for grocers with a significant online presence?

Great second point! I wondered the same, but wasn’t able to find an answer (it seems Walmart is being relatively secretive with Eden). I would imagine that if the algorithm uses the USDA standards as parameters, then the model shouldn’t assess aesthetics (see below for link to example standards for an apple). Thanks for suggesting the Wonky Food Company, it actually reminds me of Tesco’s “Perfectly Imperfect” range in the UK, which is another great waste reduction initiative.

Links:

https://www.ams.usda.gov/grades-standards/apple-grades-standards

This sounds like a really cool initiative on Walmart’s part. What I’m a little concerned about was whether this was the best use of Walmart’s resources – and if partnering with someone who could focus on this full time, such as the startup Zest Labs, who was developing a similar product already, would have been a better use of their resources. Walmart tries to do a lot and especially given their recent huge organizational overhaul (combining the in-store and e-commerce teams), I think there will be a lot of things that slip through the cracks in terms of data and systems.

What a great technology! It’s wonderful to see examples of technology that benefit a company economically while providing a social and/or environmental benefit to society.

I hope the economics are compelling enough for grocery stores to continually utilizing and investing in these types of technologies. If the resulting savings is too little, grocery stores might scrap the programs altogether and continue on with “business as usual”. It would be great to see more grocery stores sell their “ugly” produce that doesn’t make it to any store to firms like Imperfect Produce, who create a new market for ugly food.

There is a lot of room for improvement in the grocery sector, but I believe this to be a great step forward in reducing inefficiencies and waste!

I’m so glad to see that Walmart is addressing food waste problem head on! A few things come to mind on this technology –

1) it sounds like they are screening this on a box/group basis regarding produce given that they are using photos of shipments. I wonder it would make more sense for this technology to be able to scan for individual items within a box or shipment. I know that’s one step further, but think it would further reduce food waste

2) In the same vein, perhaps they could go one step further in helping farmers to sort the produce prior to sending it to Walmart. I did my blog post on TOMRA (a company in the Norway) that is sorting produce at the ag step. Sounds like they could partner with Walmart’s suppliers or with Walmart to improve food waste in the step right before in the overall value chain

Glad to see there are so many companies trying to tackle this issue!