ThyssenKrup – Steelmaker Transforms Elevators using AI

ThyssenKrupp uses Artificial Intelligence to improve reliability and usage of elevators around the world.

“It was a hard commute, and you are late to the office. Maybe it was car troubles or a cancelled train, but you are happy to finally be in the building. You speed-walk past reception, trying not to look like a lunatic. As beads of sweat rise on your forehead, you look forward to a brief respite in a quiet elevator. But then you see it: one working elevator, one “out of order”. Should you join the already long line and prepare your apologies for an embarrassingly late arrival? Or should you take the stairs and show up to the meeting disheveled and out of breath?”2. One always remembers times when technology that we depend on fails us.

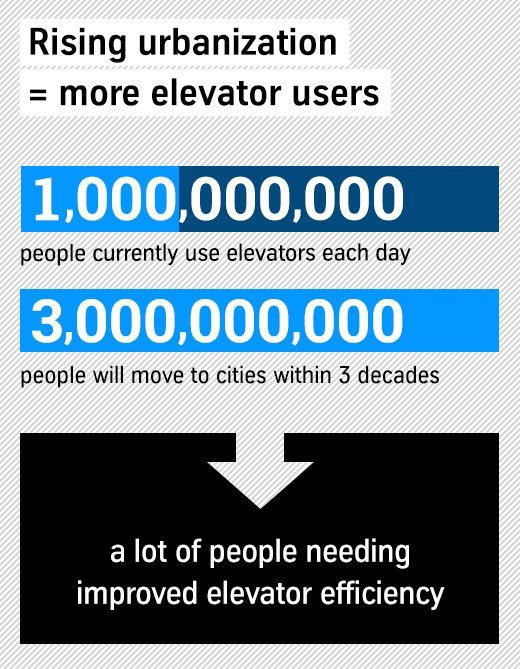

“More than 12 million elevators move one billion people every day. Worldwide, more than 12 million elevators make seven billion trips and move over one billion people every day. Yet every year, maintenance needs render elevators unavailable for a total of 190 million hours (216 centuries).”2 And these numbers are bound to grow with urbanization rapidly increasing. Fortunately, using internet of things and machine learning, the uptime of elevators is already on the rise.

ThyssenKrupp is a German conglomerate and one of the world’s largest steel producers. Apart from steel, they make high speed trains, elevators, submarines just to name a few other products. In fiscal year 2018/2019 ThyssenKrupp generated sales of €42.0 billion1.ThyssenKrupp’s subsidiary, ThyssenKrupp Elevator brings together the Group’s global activities in passenger transportation systems. With sales of €8.0 billion in fiscal 2018/2019 and customers in over 100 countries, ThyssenKrupp Elevator built its position as one of the world’s leading elevator companies from scratch in a mere 40 years’ time applying ThyssenKrupp unique engineering capabilities1.

The company launched the elevator industry’s first real-time, cloud-based, predictive maintenance solution. MAX, uses artificial intelligence and machine learning to predict issues before they occur, increases reliability, and flags replacement of components. MAX dramatically improves elevator availability and overall system efficiency.

The company deploys this data and machine learning to build a service and generate revenue. The solution is offered in three variants:

- MAX Plus

- MAX Pro

- MAX Premium

The variants offer varying levels of real-time predictive maintenance service protection. “MAX Plus provides property managers with real-time elevator status updates and traffic patterns; MAX Pro allows technicians to take immediate action when an equipment failure has been detected to reduce equipment downtime; and MAX Premium includes equipment health monitoring and predictive action to recommend preemptive action if a potential failure is detected”1.

The premium package includes a MAX team offering. To enable this, the company had to overcome several challenges. They had to establish a dedicated set of resources that included a team of experts performing a regular review of a building’s elevator usage, predictive analytics, and other relevant data. The team then provides recommendations to maximize uptime and keep building traffic moving at maximum efficiency. If the team predicts an upcoming elevator failure, they will pre-emptively send a technician to investigate and address this issue.

The company has now launched a series of products and services building on the MAX platform. They launched a robotics interface platform by incorporating the elevator interface that now provides building owners and managers improved inhouse logistics, increased productivity, and an optimized tenant experience. “In addition to robotics, ThyssenKrupp also recently launched the AGILE elevator enhancement package, which uses advanced algorithms to dynamically adjust elevator dispatching to improve people flow by up to 30 percent. The AGILE package also enables property managers to control and manage their building in new ways, including the capability to personalize elevator touchscreens and kiosks with unique messages, colors, images, or fonts. AGILE bridges the gap between traditional elevator systems and the elevators of the future by providing a smart environment of unprecedented speed, connectivity and personalization”1.

For example, with COVID-19, we learned to stand 6 feet away from each other. ThyssenKrupp immediately started working with customers to help manage social distancing in an elevator. With the easy configurability of the AGILE kiosks, they could control and dispatch the elevator to limit riders to 4 or less so they have space in the car to socially distance. However, when you limit passenger counts on elevators, you also restrict the traffic and handling capacity of the elevator system, so the company leveraged MAX to monitor traffic and alert customers when MAX sees an increase in traffic over time. This helps customers keep an eye on the elevator usage and stay ahead of any capacity constraints too.

There are several more innovations lined up for the elevator industry and the new wave of machine learning and AI. For example, video and text messaging inside the elevator cabin for emergencies, destination-based dispatching, infotainment etc. Touchscreen car operating panels (COP) and digital Position Indicators (PIs) can also be combined in various ways to solve problems for different customer personas in different building applications, and that means more value for customers. The challenge that the company will face is the potential market size of the elevator industry. However, the learnings from this industry can be applied to neighboring ones and thus this could be the next opportunity for ThyssenKrupp and AI.

Sources:

Super interesting. Not an industry vertical I would’ve predicted to be using AI in core operations but the use case makes sense. I wonder if there’s an opportunity to gradually pivot to being a software company by using their elevator distribution as toe hold to building a broader “crowd management” software

Thanks Merrill. It is interesting you mention crowd management as the company has recently used their software and applied it to manage the movement of goods in factories ensuring that they arrive on time and in the most effective manner possible!

Great post Pranav Gups! Wondering how the company deploys IoT to complement its software services. Is it built in-house? A new business line for them would be to build IoT components that could be used in adjacent use cases leveraging similar software, like Merrill’s suggestion on crowd management.

I thought this was really interesting. I understand that elevators have a long shelf life and buildings do not upgrade or change elevators that frequently. I think a cloud-based maintenance solution like this allows them to up-sell their services to clients and increase stickiness to their brand. I also like how they’ve extended its application to traffic control. I wonder if this is a solution that could be applied to traffic control in emerging markets.