Smarter, healthier, more productive: how Uptake is revolutionizing heavy industries with AI+IoT

“WE KNOW WHAT FAILURE LOOKS LIKE. Our technology has seen millions of machine failures so you don’t have to. Machines don’t have to break.”

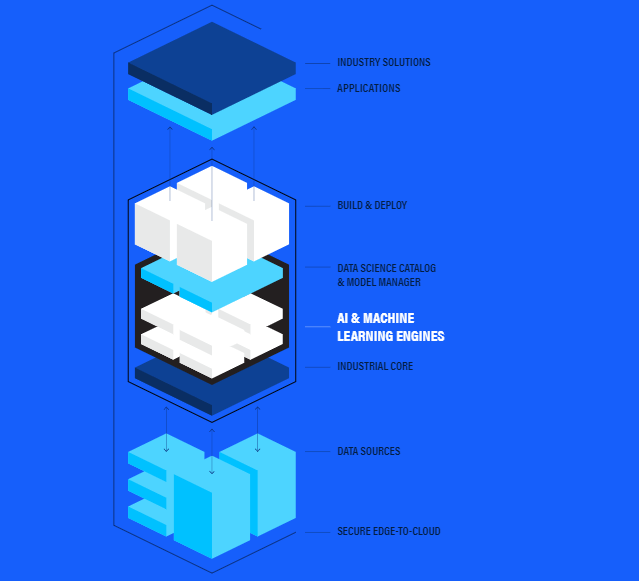

Uptake is leading the way for equipment and factories to transform into the digital era, with applications across multiple industrial sectors such as automobile, logistics, manufacturing, defense, energy, mining, agriculture, to name a few. Uptake’s Industrial AI and Machine Learning Platform leverages data science to turn large amounts of untapped IoT raw data across enterprises into actionable insight, creating higher levels of manufacturing quality, vehicle efficiency, dealer service and customer experience. [1]

Brad Keywell founded five other companies before Uptake, including Groupon. With a visionary, serial-entrepreneur CEO Uptake was launched in 2014 and quickly reached the stars. Four years after, the predictive analytics software provider grew from 50 employees to 450, and it has become the fastest startup to reach a US$2b valuation. [2]

Initially focused on the construction and mining sectors, Uptake attracted heavy equipment OEM Caterpillar as one of its first and strongest backers. However, as the company realized of the massive potential throughout multiple other industrial settings, the partnership fell apart and Caterpillar exited its investment in 2017. “To align with the updated business arrangement and to enable Uptake to pursue additional opportunities, Uptake will redeem Caterpillar’s minority investment in Uptake.” [3]

The company now serves dozens industrial clients around the world helping them determine when a piece of equipment is not performing well or about to break down. With IoT sensors Uptake collects data from industrial machinery which it then analyzes using data-science models to predict problems before they occur. [4]

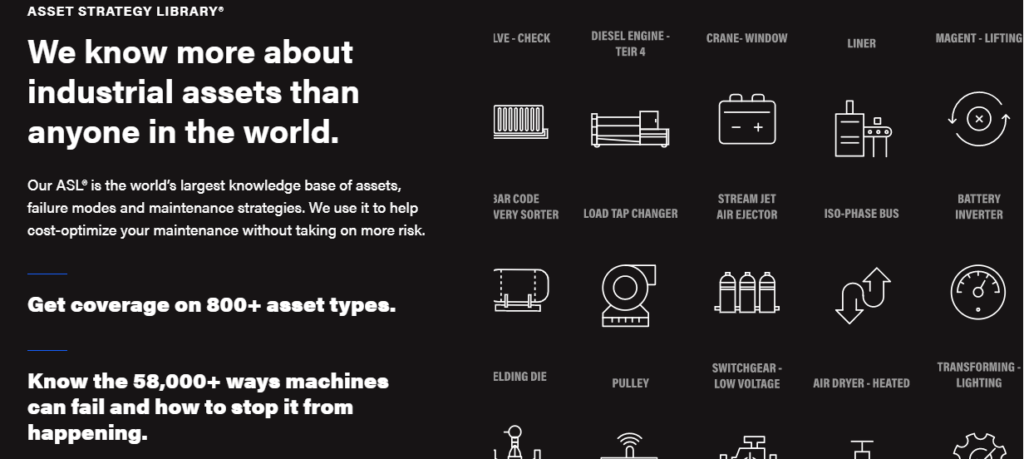

“We know more about industrial assets than anyone in the world.”

Uptake counts with a huge database of machine failures at its disposal: they claim to cover 800+asset types and to know the 58,000+ ways machines can fail and how to stop it from happening. [5] “There is no more guesswork or operating blindly involved,” says Keywell. [6] Its platform’s core functionality is the recognition of patterns that can be organized by machine type, subsystem, and failure mode. “For example, a library of known failure modes for diesel engines can be referenced and mapped to a signature of identified machine fault codes or alarms. Furthermore, because this pattern recognition is automated, it is consistently replicated across an entire fleet and an ever-expanding library of failure modes”, says Zack Novak, Uptake’s VP of Construction, Agriculture and Mining. [7]

Three concrete examples of Uptake teaching industrials how to mine data, not just dirt

Fleet management: Uptake is helping fleets reduce unplanned downtime and maintenance. “Trucks do not have to break down. Downtime should be rare and predictable” says Braden Pastalaniec, head of fleet AI at Uptake. “The true cost of downtime is somewhere between $450 to $800 per day per vehicle not including the impact on customer satisfaction.” Uptake’s platform goes beyond simply monitoring fault codes; it can monitor simultaneous streams of data in real time such as engine speed, engine oil temperature, and engine coolant temperature and identify abnormal patterns. “Fuel is the second biggest expense for most fleets, and we know that well maintained trucks save fuel.” [8]

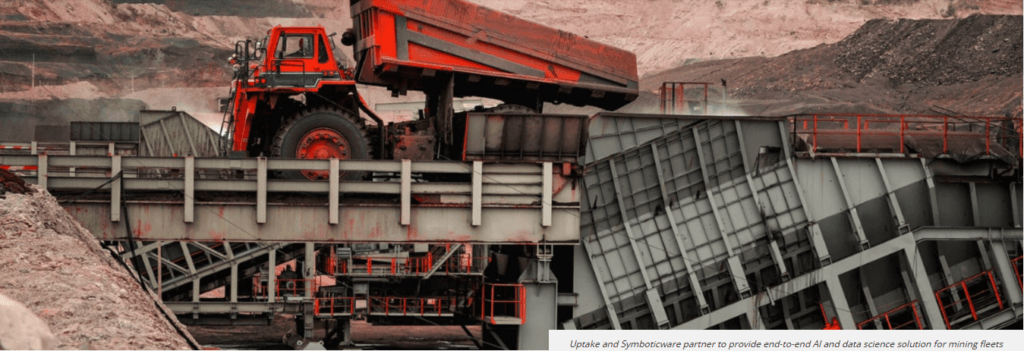

Mining: Chile’s state-owned Codelco is working with Uptake to deploy an AI-based system that will manage and predict the condition of much of its equipment and infrastructure. [9] Under the partnership, Uptake’s platform will interact with mining and processing equipment the Ministro Hales mine in the arid Atacama desert in northern Chile, covering anything from grinding mills, roasters, crushers, pumps to haul trucks and electric shovels. [10] Through a partnership with Symboticware, Uptake leverages the SymBot device to capture and analyze valuable data at many of these non-IoT-enabled dirty machines. This hardware-software combination is set to boost the productivity of mobile mining equipment through data collection from sensors, benchmarking and pre-trained AI models. [11] According to Ash Agarwal, Director of Mining at Uptake, “for an average medium-sized mining site, Uptake’s Asset IO can save as much as $2.5 million/y in haul truck maintenance, fuel and tyre costs alone.” [12]

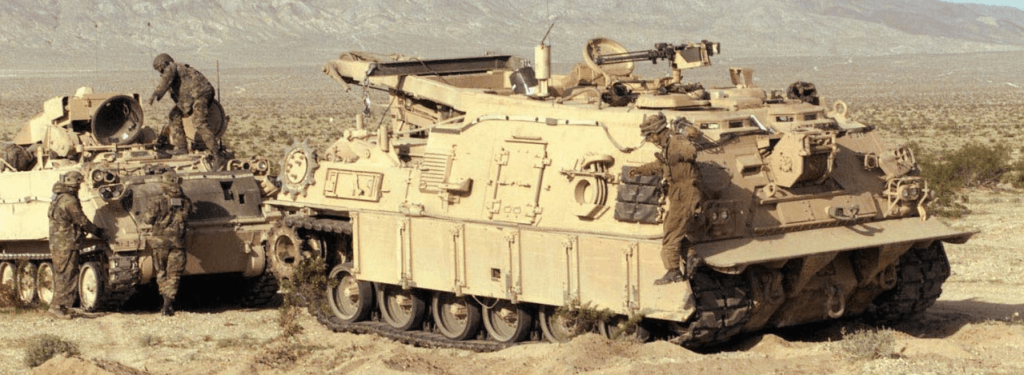

Defense: U.S. Marines are using Uptake’s Asset IO application to provide predictive maintenance and other insights into the health of its M88 vehicles. During its work with the Army, Uptake was able to identify problems on the Army’s Bradley Fighting Vehicles weeks before a maintenance failure actually occurred, and as a result was able to reduce maintenance costs and improve safety. [13] “With these actionable insights, the Army has increased operational availability, improved logistics, reduced maintenance costs, and improved safety for the men and women who serve America,” the company said. [14]

References:

[1] https://www.arcweb.com/blog/jd-power-uptake-developing-analytics-products-automotive-industry

[2] https://www.ey.com/en_gl/weoy/ey-world-entrepreneur-of-the-year-2019-brad-keywell-us

[4] https://www.ey.com/en_gl/weoy/ey-world-entrepreneur-of-the-year-2019-brad-keywell-us

[5] https://www.uptake.com/applications/asset-io

[7] https://www.curt.org/how-ai-solves-the-data-overload-problem-in-the-construction-industry/

[8] https://www.truckinginfo.com/334027/four-ways-ai-can-improve-fleet-maintenance

[9] https://www.mining-technology.com/features/copper-mining-tech/

[10] https://www.mining-journal.com/innovation/news/1359598/codelco-to-deploy-ai-solution

[12] https://im-mining.com/2019/10/18/uptake-symboticware-provide-miners-predictive-maintenance-solution/

[14] https://www.defenseone.com/business/2019/11/global-business-brief-november-07-2019/161160/

Great article, especially well researched on the examples! I believe the performance bottleneck of fleet management in industrial/military applications is indeed the ability to capture data. As such, Uptake is in a fantastic position to deliver value to its users. I would be curious to know if the startup intends to continue to develop its own suite of software products to complement the hardware. Perhaps its expertise lies in designing and making sensors, and could be better served if large customers such as the DoD used their own research budgets to develop their own machine learning models.

Cool application! Even though I worked briefly (1 year) at Shell, I learned first hand that the data available to them is sometimes “lost in translation” because the right IoT devices are not there to capture and/or “clean” the data available on-site. Aside from the huge opportunity of capturing that data, I think that the AI analysis would come in handy, especially because mechanical processes produce a lot of big data that needs to be analyzed on the spot (otherwise it gets stale), such as precision drilling/pressure testing/surface testing etc. Would be interesting if Uptake is working on “computing at the edge” applications to rapidly analyze such amounts of data. If not, that would be a great opportunity for a startup to take over!

Great article and to follow on Leonardo comment, I wonder how Uptake is positioning itself compared to in-house solutions. Shell is using a lot of data to improve its operational efficiency (cf. my last blog post) and the company is developing new predictive models powered by AI to basically get access the same visibility offered by uptake.

Any idea how Uptake manages to remain “sticky” once the sensors are put in place and the data collected? I would picture companies avoiding subscription costs by developing in-house competency in parallel.

Helpful information here. Predictive analytics for asset management is a large need and Uptake has certainly become a model effort in the application of ai to a big problem. I wonder what other applications they will expand to as time goes on!