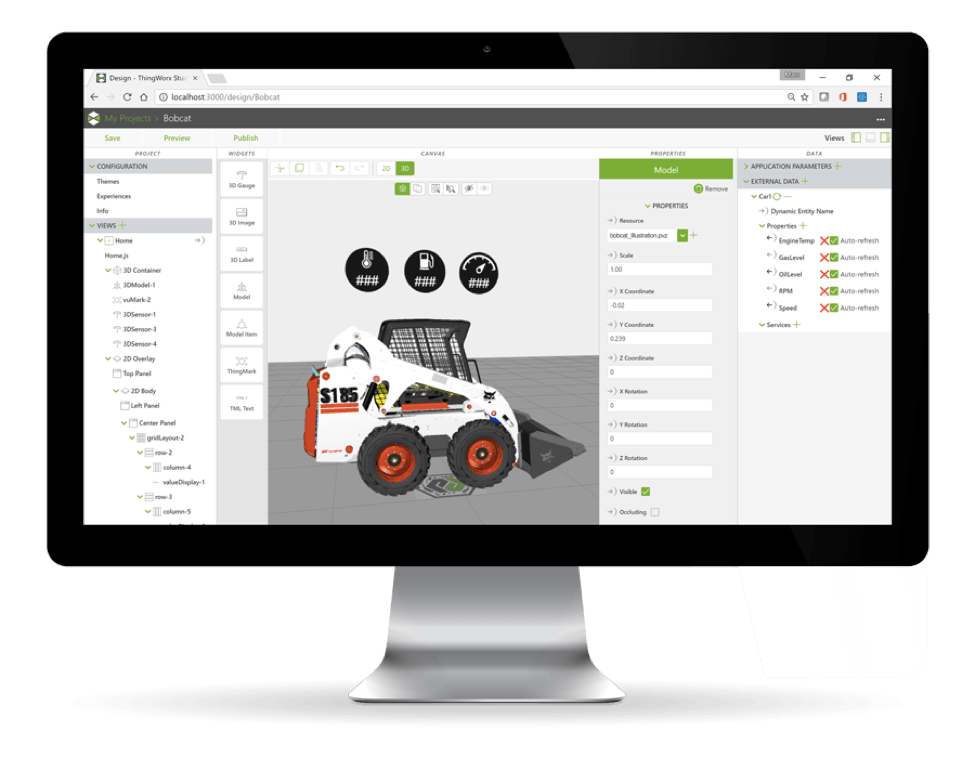

PTC’s ThingWorx Studio: AR to Reduce Maintenance Time and Cost

How an early mover can use network effects to beat competitors

Unlike most players in the Augmented Reality space, PTC has been around since 1985. PTC began by offering solid modeling software in 1986. In the late nineties, PTC offered customers product lifecycle management services, and continued to grow through the 2000s with performance tracking tools for products and parts. Starting in 2014, PTC made a series of acquisitions in Internet-of-Things (IoT) and AR companies including ThingWorx.[i] In 2017, PTC released a new product called ThingWorx Studio, a platform to help industrial customers create and publish AR tutorials/walk-throughs for their own systems and equipment.

ThingWorx Studios does not require any programming skills and is designed specifically to quickly integrate the client’s existing CAD data. Once the tutorial or walkthrough is created and published, a user can point the camera on their iPhone, iPad, or HoloLens to the product they need to operate and see the procedure unfold before their eyes.

Value Creation

ThingWorx Studio has much to offer PTC’s traditional customers, which include industrial and consumer equipment manufacturers. With ThingWorx Studio, content creators from Caterpillar, Nespresso, or Embraer can create AR instruction manuals that can be used by consumers or by maintenance technicians.

For example, a lab technician using a blood analyzer might initiate an automatic cleaning cycle. Today, if the cleaning sequence fails, the technician must call the manufacturer and wait for a service specialist to arrive. Thanks to PTC, the lab technician can now simply point their iPad camera to the blood analyzer through the ThingWorx View app, and receive a visual walkthrough of how to manual clean the equipment after scanning a ThingMark – PTC’s version of a QR code.

The time saved through the access of this AR experience can be multiplied for innumerable other servicing scenarios. Not only can users perform repairs on the spot, but general technicians can more easily attempt procedures they don’t often do. The value is therefore created for both the end user and for the industrial or consumer equipment manufacturer.

Value Capture

ThingWorx Studio is still only available for free trial, but has many possible future models to monetize their tool. PTC could license the Studio software to clients through a SaaS model. Given that the Studio tool is specifically designed to not require programming, then PTC does not need to train anyone within client companies. PTC could also capture the value created by the View app with enterprise fees based on number of users.

How they can further grow in the future

An exciting opportunity for PTC exists in capturing the value of network effects. The value capture methods mentioned above work well when selling the PTC AR platform to manufacturers of service suppliers like Caterpillar or Embraer. However, PTC can create value in a different way for companies that use the industrial equipment from multiple manufacturers. An example of this might be an airline like Qantas – an existing PTC customer. Qantas needs to service and maintain aircraft from both Boeing and Airbus but not Embraer, Gulfstream, or Bombardier. They also need to service ground equipment and other vehicles from a few different manufacturers. If PTC can ensure that they can provide the AR experience for all the equipment of a Qantas, then Qantas will be less likely to switch to another VR provider. For this reason, PTC should focus early sales on securing the entire array of manufacturers for a specific set of clients rather than try to capture the entire category of competing manufacturers. In other words, PTC should secure all the manufacturers that supply Qantas, rather than get all aircraft manufacturers on board. By doing so, PTC will begin to leverage network effects through first mover advantage.

[i] http://www.ptc.com/about