Li & Fung Digital Platform: Transforming Global Supply Chain

Li & Fung, the Hong Kong-based supply chain and logistics giant, is aiming to digitalize every step of the retail supply chain. The objective is to make data flow seamlessly, providing better visibility to both customers and suppliers around the world, and enabling them to come up with faster and smarter business decisions.

An innovative approach to SCM

During the last few years, supply chain management and logistics companies have been increasingly adding technology elements to their value propositions in order to improve the service level and to offer more efficient ways to create value for its customer either to source raw materials, to operate their warehouses or to manage and track the transport of goods.

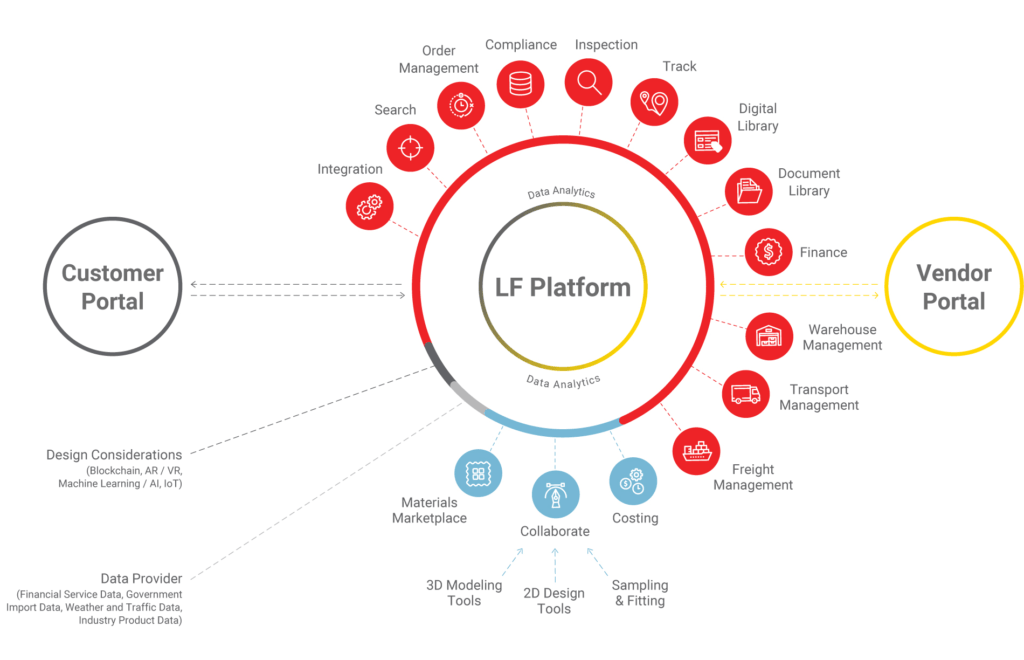

Since 2017, Li & Fung (LF) has been trying to bring that same technologization process to the next level, especially in the apparel business. Through their proprietary LF Digital Platform, LF goal is “to create the supply chain of the future to help our customers navigate the digital economy and to improve the lives of one billion people in the supply chain”[1]. The Digital Platform’s main objective is to integrate both the customer and the vendor portals into a unified platform that allow both parties to improve SCM operations from collaborative designing to digital sampling, through online costing and fitting reviews, transforming analog, manual work into digital solutions, all powered by data analytics. LF considers its size and scale as a unique advantage to position its platform as the pioneer to transform the global supply chain with integrated end-to-end data flow[2].

How the Platform Creates Value?

– Easier material sourcing: LF has developed a digital marketplace for raw materials to manufacture apparel, seamlessly connecting thousands of retailers and suppliers, in a reliable manner, anywhere and everywhere. This element of the platform eliminates the need for visiting trade shows abroad and meet physically with suppliers, reducing the procurement search-and-connect cycle time from two weeks to just a few hours[3].

– Quicker design iterations: By leveraging 3D virtual design capabilities and standardized processes, the Digital Platform is allowing customers to have a direct impact on the operational level. For instance, case studies show that designer productivity has tripled; sampling and fitting costs have been reduced by half, and speed-to-market has increased as much as 40%[4].

– Working closely with production plants: LF team also has also developed a Production Platform, making it easier to track the WIP inventories and giving both suppliers and customers better visibility to capture production defects earlier. The same tool helps streamline quality-assurance activities and improves decision-making processes and communications.

– Becoming a better touchpoint for partners: Having a single, central point of touch for vendors and customers, with access to value-added tools and all the related information, make SCM operations easier to manage and benchmark.

Value Capture Strategy

The development of the Digital Platform means a huge business opportunity for LF to capture more commercial volume and to integrate its operations vertically along the supply chain. Besides attracting more retailers and suppliers with the easy-to-use platform, the fact that the tool helps them to reduce time-to-market gives LF higher turnover, which should lead to higher revenue. Moreover, offering new value-added services (e.g. 3D design) to their users means new revenue streams at higher margins, too.

Sources

[1] Spencer Fung, Li & Fung CEO. Analyst Day Presentation, March 2017, page 4.

[2] “LF Digital Platform” – https://www.lifung.com/supply-chain-innovation/lf-digital-platform/#content-area

[3] Sean Coxall, Li & Fung President for Supply Chain Solutions. Digitalization Update Presentation, 2018, page 4.

[4] Sean Coxall, Li & Fung President for Supply Chain Solutions. Digitalization Update Presentation, 2018, pages 8-19.

Interesting post, Gregorio! One thing that struck me about the innovations you highlight above is that they all help strengthen Li & Fung’s platform against potential disintermediation between customers and vendors (a constant threat for platforms). For example, the virtual design capabilities and WIP visibility features you mention both offer great value to customers that they would lose if they chose to move their transaction off platform.

I did some research into the history of Li & Fung and it looks like all the way back since 1999 there have been disintermediation concerns (see attached note from their Chairman) but the company has continued to stress that they will use technology to offer more integration services across the supply chain to their customers. It seems their early focus on features that protect them from disintermediation may be one of the key reasons that they have been able to grow successfully for so long.

https://www.lifung.com/wp-content/uploads/2018/02/ar1999_07.pdf

The most amazing thing to me about platforms is their ability to aggregate supply and demand so that it’s a win for every party. It’s like diversification – a magical, essentially free benefit to both sides. Scale seems to be absolutely critical to Li & Fung’s success here: by aggregating thousands of manufacturers (suppliers) and thousands of retailers (buyers) on the same platform, LF is able to lower search costs as well as substantially lower transaction costs by, for example, providing volume discounts, enabling more efficient production runs, optimally allocating production across multiple factories, and providing access to technology and digital infrastructure too expensive for a single player, all savings and benefits smaller players would have little access to without a platform like LF. Your comment about LF eliminating the need for retailers and manufacturers to visit tradeshows and physically meet reminds me of how Alibaba dramatically lowers search (and transaction) costs by solving the online purchase trust void. The efficiency gains here are sort of amazing to think about: oversimplifying in this case, instead of each supplier meeting each retailer (100 suppliers x 100 retailers = 10,000 meetings), i.e., what would be required to recreate the network without LF in the middle, just LF meets each supplier and retailer (100 suppliers + 100 retailers = 200 LF meetings), a dramatically smaller number! Plus, from your description, it seems LF has taken advantage of the amount of data on production it’s seen over the years to optimize allocation and planning algorithms, an efficiency gain over and above what the full network of retailers and suppliers could achieve even if those 10,000 meetings did take place. That sort of accumulated expertise benefit extends beyond the planning element to the entire supply chain (e.g., virtual design, as you noted). Truly amazing platform with immense value creation opportunities.