Invisalign – 9/10 dentists recommend additive manufacturing

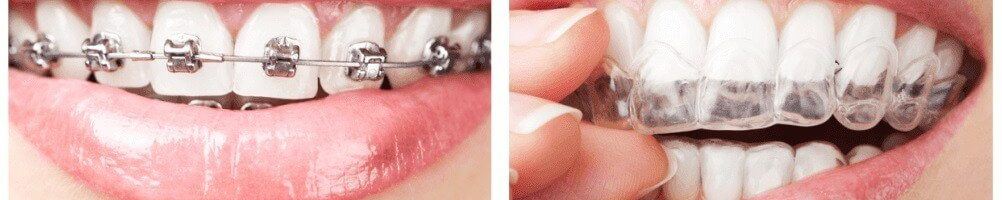

Digital transformation, in the form of additive manufacturing enabled by computer-aided design and optical scanning hardware, has led to the creation of a new treatment modality for misaligned teeth – clear aligners. Invisalign has been the forerunner in commercializing this new type of treatment and has been wrestling market share away from conventional metal braces manufacturers such as American Orthodontics.

Winner: Invisalign

Wholly owned and operated by San Jose-based Align Technology, Invisalign is a clear aligner system that was designed to straighten moderately misaligned teeth due to crowding or over-spacing on the jaw. The system consists of multiple sets of clear plastic “invisible” aligners that fits over both the top and bottom row of teeth. The production of the aligners relies on the use of 3D printing to accurately replicate the form of the user’s teeth. Users will typically use 12 to 20 sets of aligners to progressively adjust the position of their teeth over a period of 6 months to a year.

Loser: American Orthodontics

American Orthodontics is a manufacturer of orthodontic supplies and equipment. Its best-selling product portfolio mainly consists metal orthodontic braces systems such as the Master Series brackets and Empower self-ligating brackets [1]. Users typically require an orthodontist, dentist or oral health therapist (depending on local regulation) to install and periodically adjust the braces.

Why and how is Invisalign winning?

Invisalign is winning because it placed strategic bets on the use of additive manufacturing and digital intraoral scanning to create a dental treatment modality that allows for low cost and high throughput mass customization.

The following steps outline how Invisalign clear aligners are made:

- A dentist uses a handheld intraoral scanner to take a digital impression of the patient’s teeth. The result is a Standard Tessellation Language (STL) file that can be used by Computer-Aided Design (CAD) software.

- With the digital impression, the prescribing dentist uses proprietary software to automatically generate a series of digital models of aligners. The model parameters of each set (eg. spacing, torsion, angle) is calculated in a way that the gradually straightens the patient’s teeth as he/she progresses through the treatment plan.

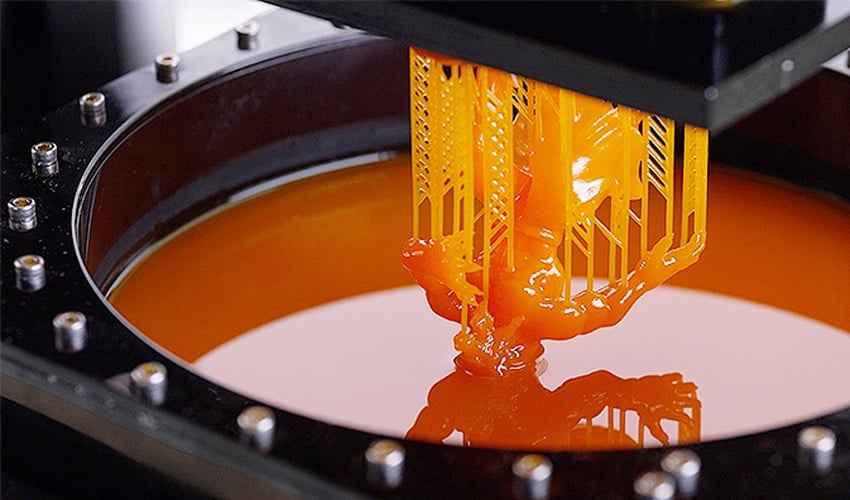

- Using the digital models, Invisalign uses stereolithography (SLA) [2] printing to create a plastic mold for each set to be produced. SLA printing is a form of 3D printing that uses high-powered lasers to solidify liquid plastic resin into a specified shape. Invisalign is not able to 3D print the aligners itself because the liquid resin used must be photo-sensitive.

- In the thermoforming step, transparent medical-grade plastic is heated and pressed against the customized SLA-printed molds, thereby creating the clear aligners.

As a result, Invisalign can produce a series of transparent teeth aligners that is customized to each patient’s teeth and treatment plan requirements. In so doing, it creates value for its customers, the patients, in the following ways:

- Visual aesthetics. The aligners are made of transparent plastic that are roughly 0.3 mm – 0.7 mm thick. As such, they are not very visible on the wearer, much less so than traditional metal dental braces.

- Easy installation. With the customized aligners precisely modelled after the customer’s teeth, no painful molar hooks or enamel adhesives are needed to affix the straightening device to the patient’s teeth.

- Cheaper than metal braces. As the sequential steps of alignments are created algorithmically in CAD software, patients do not require a dentist to check and tighten the straightening device periodically. This significantly reduces the treatment cost for the customers.

Why and how is American Orthodontics losing?

In contrast, American Orthodontics has been on a sustaining innovation path by making incremental improvements to its metal dental braces products. The company uses electrical discharge machining (EDM) [3], to create precise metal parts such as brackets, hooks, coils and archwires that make up bulk of conventional metal braces. Invented in 1943, EDM is a subtractive manufacturing technique that does not provide the level of manufacturing accuracy and customization that SLA does.

American Orthodontics sells standardized metal parts, leaving it to the dentist to customize the shape of the braces to the treatment plan requirements. As a result, the company is ceding market share to Invisalign as its product is loses out to clear aligners in the following ways:

- Aesthetically displeasing. Metal braces are highly visible and for some adult users, embarrassing to wear

- Lengthy and painful installation. Hooks, wires and dental cement must be used to put on the braces.

- A highly trained dental practitioner has to manually check and tighten the braces periodically, which adds to the total cost of treatment significantly.

In conclusion, the novel combination of additive manufacturing, computer-aided design and optical scanning capabilities has allowed Invisalign to develop and market a product that creates jaw-dropping value for its customers, vis-à-vis the conventional alternatives.

Sources:

[1] Americanortho.com. (2019). .:: American Orthodontics | Products ::.. [online] Available at: http://www.americanortho.com/products.html [Accessed 24 Sep. 2019].

[2] All3DP. (2019). Stereolithography (SLA 3D printing) – Simply Explained | All3DP. [online] Available at: https://all3dp.com/2/stereolithography-3d-printing-simply-explained/ [Accessed 24 Sep. 2019].

[3] Xactedm.com. (2019). What Is EDM? – How Does Electrical Discharge Machining Work? : XACT. [online] Available at: https://www.xactedm.com/edm-capabilities/how-edm-works/ [Accessed 24 Sep. 2019].

Invisalign provides a great example of how business innovation is closely tied to technological innovation. Advancements in manufacturing techniques and digital scanning provide key support for the company’s existence. Invisalign was the first disruptive investor, however, increasingly new wave of competitors appears. Concretely, players like Smile Direct Club learn form Invisalign and use their second mover advantage and lower costs to capture customers.

I’m curious what will be the reaction of professional orthodontists – I’d be stressed if I spend my youth studying the subject and investing a lot in this to realize that market for my services decreased twice fold. Or instead, it will drop the pricepoint and new customers inflow will balance the drop in bracket maintenance revenue?

What are the other similar options? Flat feet? Pillows? Seats?

As a current user of braces, I can attest to the difference in customer experiences between using a 3D printed Invisalign(current) and my former traditional metal braces. Not only is Invisalign more discreet and light-weight, but I love the fact that I get a new prescription every few months. The main reason, as alluded here, is that teeth are not fixed, but rather they are allowed to move with a higher degree of freedom to their desired location. This allows the patient to provide constant feedback during the process, and raise any irregularities in teeth direction, whereas traditional braces are less flexible to adaptable to sudden requests. At the same time, as someone mentioned earlier, I am concerned that competitor companies like Smile Direct Club might cling on to Invisalign’s success by offering a lower quality product that mimics the benefits of Invisalign without providing the assurance that the final result of the procedure will be the desired result. I know some people that have “messed up” their teeth by using these products, as they are not provided by trained orthodontists, but rather are cheaply mailed to end-user. Beauty is pain, and its expensive too, so watch out for lower quality products!

This was a really interesting read! It is great to see the shift from metal braces to Invisalign.

As mentioned earlier, there are a few big entrants with similar business models from SmileDirectClub, Candid Co. It will be interesting to see how these firms use innovation in being able to capture even the more complex, and lucrative, cases and ensure they do not mess up sets of teeth?