Hyundai Heavy Industries – a winner in navigating the course of shipbuilding through digitization

How the largest shipbuilding company is revolutionizing the world’s oldest and most traditional manufacturing industry through integrated design and engineering.

With 90% of the world trade managed through maritime transport, the shipbuilding industry continues to be at the mercy of global economic fluctuations. While the shipbuilding industry has for many years managed to survive economic peaks and slumps, the high capital-intensive nature and increasingly competitive landscape have made it difficult for many shipyards to stay afloat.

Hyundai Heavy Industries (HHI), the largest shipbuilder and global market leader (10% market share)[1], is helping change the course of one of the world’s oldest and most traditional manufacturing/heavy industries. With many of today’s shipyards shutting down due to over-capacity, HHI has successfully managed to remain competitive by re-evaluating and revolutionizing its shipbuilding operations through the adoption of digital technologies.

While many original equipment manufacturers (OEMs) continue to incrementally improve their individual component performance (increasing efficiency and reducing operating costs for ship owners), HHI has extended lifecycle management to the shores of its shipyard. By integrating engineering and design software solutions into its manufacturing process, HHI is optimizing its workflows – resulting in reduced costs while maximizing revenue streams.

As ship owners’ specifications increase with technological advancements, so do complexities in shipbuilding – making it harder for shipbuilders like HHI to manage the mass-manufacturing process manually with the accuracy and efficiency required. The ultimate goal for HHI is to deliver a product (typically averaging $120 million) on time, on budget and to the correct specifications.

As changes occur during the building cycle of the product, the shipbuilding process becomes less linear and modifications need to be made. Many inputs across various disciplines are required (structural, piping, electrical etc.) at different times. As the design evolves, information lags are created causing errors that become costly to fix. These errors are further multiplied as teams work off different assumptions, ultimately increasing the cost of production.

This digital technology (integrated design and engineering) adopted by HHI centralizes and takes control of all the ship’s inputs. By managing the shipbuilding process through a robust and flexible solution that communicates critical design changes (to the right individuals at the right time) it allows for cost savings of upwards of 15%[2].

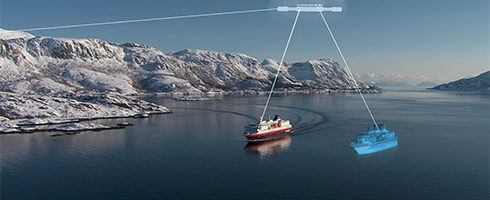

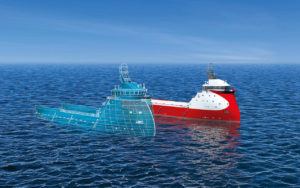

Through the creation of a “digital twin” the design is captured along the product’s manufacturing lifecycle, allowing for full visualization of the product (via augmented reality) and making adjustments as required. The benefits of having a digital twin are extended throughout the ship’s operation, helping technicians anticipate and address malfunctions at sea and/or identify and alert shipowners regarding required/upcoming maintenance activities (reducing a ship’s ideal time and extending the useful life).

Moreover, by feeding the centralized/integrated system with data HHI is also able to leverage advancements in predictive analytics to simulate different scenarios that help improve ship designs all while modernizing the shipbuilding process – making it more affordable and efficient across the entire value chain.

[1]Welcome to Hyundai Heavy Industries. (2018). English.hhi.co.kr. Retrieved 1 February 2018, from http://english.hhi.co.kr/biz/ship_over

[2] Eckstein, Megan, and View →. 2018. “Newport News Creating ‘Smart Shipyard'”. USNI News. https://news.usni.org/2016/05/23/newport-news-smart-shipyard.

Fascinating post. This is a great illustration of how powerful digital technology can be in transforming a less “sexy” industry, with a much larger impact than the more trendy digital technology that gets most of the press. Shipping is such an importunate aspect of the global economy, so having a digital innovation that optimizes the ship building process is incredibly cool. Also, I love that this incumbent took the initiative and didn’t let themselves be disrupted by an outside tech firm.