Applied Materials- When machines talk to each other

Applied Materials is using machine learning and advanced statistical algorithms to improve semiconductor yields

Applied Materials- when machines talk to each other

Applied Materials (AMAT), the global leader in Semiconductor manufacturing equipment has started on a path for the smart fab, a manufacturing facility where the machines talk to each other and transmit data from tool to tool to improve quality and efficiency. One of the most interesting components of the Smart Fab is the Automatic Defect Classification (ADC) server.

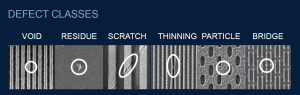

The ADC is a server that automatically classifies images of defects from Defect Review (DR) tools. As seen below, defects in Semiconductor manufacturing process can be a scratch on the surface, a particle or an uneven critical dimension. To understand how tiny these defects are it is worth mentioning that the latest generation DR tools are capable of detecting defects the size of 10 nano meters, which is almost on the atomic level (to be precise 10 nanometers are equivalent to 20 silicon atoms).

So how do does the ADC work and uses data?

The ADC server is connected to several DR tools that constantly send the server pictures of defects. The ADC server is essentially a rack of hundreds of image processing (IP) computers that analyze the images and compare them to a database of known defects. Since each customer has its own process with unique defects, Application Engineers use machine learning tools to teach the server how the customer’s unique defects look. In production once an image is sent to the server for classification, the IP computers use advanced statistical algorithms to compare the image to the image database, to complete the classification.

Value Creation

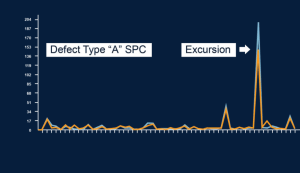

Before the invention of the ADC server, semiconductor manufacturers had to employ a team of engineers who would sit all day and classify images manually. Therefore having an ADC server directly contributes to cost reduction by eliminating manual classification. More importantly, the ADC server speeds up and improves data integrity of classification. This faster and improved classification contributes to a tighter statistical process control (SPC) in the fab which improves semiconductor yields, which is a significant value driver.

Value Capture

The ADC server comes with a hefty price tag of several million dollars. however its price tag pales in comparison to the bigger sales it enables. Since the ADC works only with Applied Materials Defect Review tools, it encourages customers to award a higher share of DR tools to Applied Materials. Many customers tend to split their Defect Review Capex between AMAT and its competitor, typically 75/25 or 50/50. The ADC server has led to customers awarding 100% or 80% share to AMAT, which can mean 10-15 tools at a $3M per tool.

Thanks for a great post about a fascinating industry, Oded! Your analysis of AMAT’s value capture made me think about the competitive reaction to ADC – if the ADC server has such a huge impact on the share of DR tools which goes to AMAT then I wonder how competitors are responding to this shift, are they working on their own algorithms? Are they reducing the price of their own defect review service? It would be interesting to see how this industry evolves in the face of this innovative machine learning development.

Following Noam’s comment, how expensive would it be to build your own algorithm? With data-science being the trend right now, I don’t think it would be very hard to either build your own team or outsource to a data-focused software company to build such a algorithm that detects differences in images. If this is the case, how could Applied Materials leverage its first-mover advantage? Through network effects of its existing customer base?