WAIT A MINUTE, I WILL PRINT… YOUR EAR

Fast pace of digitization is having a tremendous impact on the opportunities for the medical industry, specifically, enabling technology to react faster and more efficiently to the current health needs. Bioprinting is one of such digitalization outcomes, shifting the need for physical human organ to the need for fast 3-D printer.

You would say: people live longer today. Indeed, medicine has improved dramatically over the last 100 years or so. On the flip side, however, this means that as we live longer, our organs tend to fail more, which leads to demand for organs transplants exceeding supply. To be precise, in the last 10 years, the number of patients requiring an organ has doubled, while the number of transplants hasn’t changed much. Each year, around 30,000 lives are saved thanks to organ donors in US, according to the United Network for Organ Sharing. While this figure seems big, every 10 minutes one more person is wait-listed for transplant, and on average, 21 people die each day because they don’t get the organs in time.

Such health crisis has boosted development of regenerative medicine and, in particular, bioprinting (3-D printing of human tissues and organs). Imagine: next time you just order yourself a new ear, and it is printed in 30 minutes instead of being awaited for year!

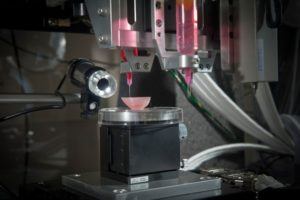

Put simply, bioprinters look like large industrial printers, that instead of usual ink use a biological ink: a mixture consisting of human cells from biopsies or stem cells. 3-D printer is programmed to print different cell types into required prcise three-dimensional shapes. The idea behind it is that when placed in the body these will be able to blend with existing tissues or even substitute a deceased organ.

There are several bioprinting companies in US now, but the most prominent one is Organovo – startup, based in California, that has started getting attention to its work since 2011 and is now enjoying advantage of the first mover to address the critical unmet need.

Organovo’s long-term goal is to produce tissues from cells on demand for the doctors and, hence, remove the necessity to wait for a limited supply of donor transplants. Organovo has also built models of human kidneys, bone, cartilage, muscle, blood vessels and lung tissue. Organovo covers the U.S, Europe, and Asia markets, and works with 10 of the Top 25 global pharmaceutical companies, such as Merck, Roche, Janssen, Astellas and Bristol-Myers Squibb, alongside with partnering with Harvard and Yale universities. For now, its core value proposition remains recreating liver and kidney cells for the drug testing needs of large pharmaceutical companies. This innovation would help pharmaceutical companies to address gaps in 2D and animal models, but also significantly reduce the cost, predictability and speed of drug discovery. For example, while traditionally drug tests for toxicity can take months and cost $1 billion, Organovo liver cells tests can provide results within 7 days with considerable budget savings.

FUTURE: opportunities and challenges

Some sources claim that implementation of 3D-printed replacement tissue for the most important body organs might be available already as soon as in 10 years. And Organovo has a strong ambition (and potential) to be the first company to lead this breakthrough. Per the company’s estimates this new market could offer a huge opportunity of over $1 billion.

Another big opportunity for Organovo is expanding its operations into skin reproduction and partnering with cosmetics industry. First seeds in this direction have already been sown in 2013 when Organovo signed contract with l’Oreal. This partnership aims to turn current 3D printed skin prototype into actual 3D printed human skin, which could be used for commercial purposes. In fact, if successful, such partnership can open the door to other industries, reliant on the skin tissues (for example, targeting dermatology or skin cancer researchers).

Said that, there are still many obstacles ahead of the company right now. First is the adoption level. Organovo’s key competitors are traditional 2D cell cultures and animal models. Pharmaceutical companies are keen on using what they are familiar with and what they are trained for. Vast work needs to be done on education, explaining why 3D bioprinted tissues are better than any other currently available options. Given that safety is one of the top decision-making factors in this industry, Organovo needs to ensure relevant research support. Second restriction is regulations. To make its products available for the market, Organovo needs to get U S Food and Drug Administration approval for any new products, which sometimes can take decades. Since this area is so new, it is also difficult to predict whether some products could be banned in the future once more research is done in this area and any serious concerns are discovered.

Word Count: 734

http://www.cnn.com/2014/04/03/tech/innovation/3-d-printing-human-organs/

https://www.ted.com/talks/anthony_atala_printing_a_human_kidney/transcript?language=en#t-34000

http://www.cbsnews.com/news/tech-trends-that-will-make-waves-in-2016/

https://pharmaceuticalintelligence.com/2016/04/05/update-on-fda-policy-regarding-3d-bioprinted-material/

This is a really interesting post, outstanding from all the big data / internet topics. I was really amazed by the advanced 3D printing biotechnology nowadays could achieve this great job! I once also did some analysis on 3D printing industry, and learned that its best usage would be in healthcare and industry goods, esp. auto and aviation. 3D printing an ear would be just a starting point. In the future, we could expect large bunch of 3D printed spare parts of cars, airplanes and even spacecrafts. Please allow me to return to the big data topic – once we achieve the mass production of 3D printed spare parts, can we also put chips into the parts and track the operation of each product. From analyzing the operation condition of all products, we could estimate any potential breakdown and prevent it beforehand. 3D printing provides us with huge room of imagination!

This is a great example of the digital revolution, more specifically how much societal good can come out of it. Often we only hear of privacy/security concerns, but this underscores the potential to leverage digital technology to change lives. To your point, I think there are some substantial hurdles to overcome before printed organs can become the standard. I have no idea how we get potential patients even comfortable with the idea of a printed organ, but I guess when its life or death the barrier to trial is low. Given the existing need for organs, I wonder what can be done now to push different stakeholders in order to accelerate the technological development, regulatory approval and general adoption.

Thanks for sharing! This technology reminds me of the advances in stem cell research as well where they’re trying to recreate organs based on a person’s own cells to lower the risk of the patient’s body rejecting the organ (https://www.bostonglobe.com/business/2013/11/18/stem-cells-from-patient-may-stop-immune-system-from-attacking-transplanted-organs/HjhSGLT1bNTnO2XBsjjIZN/story.html)

On the ear in particular, your post also reminds me of the mouse that was used to grow human ears: http://www.dailymail.co.uk/news/article-3414756/Scientists-grown-human-EAR-rat-say-able-use-humans-five-years.html

I imagine that the most beneficial application for these ears in reconstructive surgery are for people who are born with microtia. The options have thus far been taking rib cartilage from the patient to reconstruct an ear or to use a styrofoam-like material (http://www.drjohnreinisch.com/microtia-treatment).

I love that you chose this topic, Iryna, because I am so so so excited about 3D printing!! It will completely revolutionize healthcare delivery. I actually think patients will not be resistant to receiving 3D printed organs since human cells are used to create them – the composition is essentially the same. Not only could these organs potentially save the 21 lives a day you quoted, they would also drive down the healthcare costs associated with patients receiving bridge therapy while awaiting surgery – such as tri-weekly dialysis treatments while waiting on a kidney transplant. As for the skin printing, it would be phenomenal for burn or acid victims, as well as for patients with disfiguring birthmarks. The possibilities are truly endless!

Thanks Iryna. I’ll really be interested to see how this plays out — I think that adoption and regulation are two big hurdles, as you mentioned, but I think once this technology becomes more mainstream the next challenge will be scaling it so the average person has access. I wonder if this technology will be, at least at first, only accessible to the wealthy and therefore beneficial to only a few people with the need. Additionally, I also wonder what ethical issues the public at large will take with “machine creation” of organs. I could see this potentially getting some pushback from special interests like religious groups, who have already voiced significant opposition to stem-cell technology in several cases. Very interesting post!

I find this post really interesting Iryna. As Nelly-Ange mentions in her comment, the possible uses are really diverse and have a positive impact on the healthcare industry overall. Having said this, I am curious as to how this could affect the normal procedure and operations of hospitals that would use this technology. Assuming that the process gets FDA approval and is easily adopted by customers, it would be interesting to see how the supply and demand develop and how production responds to the demand. My guess would be that it would have to be an on-demand production process, but maybe there would be ways to have “stocks” of organs for urgent use? Would people be able to order “security organs” just to be safe? And hence, how would this affect the traditional transplant procedures? I really hope we see this technology develop further, so it can be applied in a way that saves as many lives as possible.