Thinking Outside the Box

Reducing the carbon footprint of cardboard packaging

Every Tuesday—garbage day—I feel a twinge of guilt as I take this week’s pile of Amazon boxes to the curb. “But, don’t worry, they’ll be recycled”, I reassure myself. I might not be the only millennial with an online shopping problem, but our collective e-commerce habit is contributing to humanity’s much more troubling climate change problem.

The United States containerboard industry produced 35.4 million tons of product in 2014.[1] While overall production growth of containerboard (the type of bulk paperboard used to make corrugated cardboard boxes) has recently been just 1-2%[2], the gains from companies optimizing the design of packaging they use, thus reducing material and freight costs, have been offset by increases in demand from e-commerce companies.[3]

Even though 90% of cardboard is eventually recovered and recycled, greenhouse gases are emitted across the life of a cardboard box.[4] The industry recognizes this and took steps reducing its greenhouse gas emissions by 32% from 2006-2010.[5]

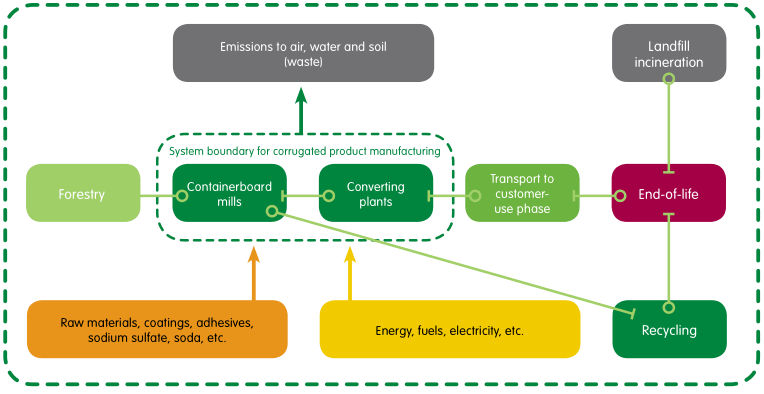

Cardboard is made from raw wood fiber, sourced from a combination of trees and post-consumer recycled material. While certain pulp and paper products can be made from 100% post-consumer recyclables, the durability requirements of the high-quality corrugated cardboard products used for packaging requires the addition of new fiber in all new product. Newly produced cardboard contains an average of 46% recycled fiber.[6] The rest comes from newly harvested trees – trees that absorb carbon dioxide, helping to abate the impact of greenhouse gases on the earth’s climate. Compounding these effects of deforestation is the industry’s enormous electricity and fuel consumption in the processes of milling, manufacturing, and transporting finished goods to the customer. At the end of its life, the 90% of cardboard that is recycled uses additional energy through this process, while the 10% that ends up in landfills decomposes or is incinerated, emitting methane and carbon dioxide.[7]

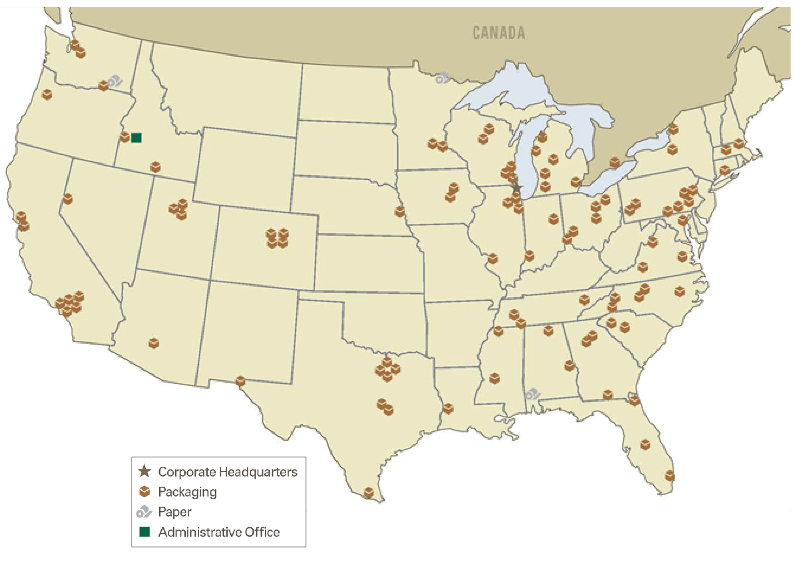

- PCA is one of the most vertically integrated players in the industry, with its leased forests, mills and manufacturing plants geographically dispersed across the country. PCA is able to save significantly on transportation costs (primarily from using less fuel) across its supply chain because it sources its fiber from forests near its facilities and customers are typically located no more than 150 miles from a facility.[12]

- PCA products include no more material than necessary and are shipped in containers that are the most effective size to optimize transportation costs.[13]

- PCA uses recycled material consistent with the industry mix and sources 95% percent of its new fiber from sustainably managed forests certified by the Sustainable Forestry Initiative. Contrary to popular perception, managed forests use land productively and industry-wide have contributed to net replanting with an increase of 14 million acres of total forest area in the U.S. between 2007 and 2012.[14]

- PCA sources as much energy as it can from its self-generated byproducts (which produce steam, and thus electricity), and the rest from purchased fuels. In 2015, their mix was 59% from by-products, and 41% purchased fuels (of which 54% was natural gas, 32% wood waste, and 14% coal).[15]

While PCA and the containerboard industry as a whole have made concerted efforts to reduce their environmental impact, more could be done. PCA should fully commit to its sustainability initiative, sourcing 100% of its new fiber from SFI managed forestry, and through new technology, push the envelope on the mix of recycled fiber used in new product. And while the reuse of their by-products as fuel sets a commendable standard, it is disappointing not to see a higher mix of low-carbon or renewable sources in their purchased fuels. As the industry moves increasingly towards rightsized packaging, reducing overall production levels, PCA and all of its competitors will need to think through how their revenue models, which have historically been driven solely by volume, will need to evolve into more solutions-based revenue streams such as working with clients to design innovative types of packaging.

(781 words)

References:

[1] Matt Richtel, “E-Commerce: Convenience Built on a Mountain of Cardboard,” New York Times, February 16, 2016. http://www.nytimes.com/2016/02/16/science/recycling-cardboard-online-shopping-environment.html

[2] Packaging Corporation of America, “Form 10-K,” United States Securities and Exchange Commissions, February 26, 2016. https://www.sec.gov/Archives/edgar/data/75677/000007567716000030/pkg1231201510k.htm

[3] Matt Richtel, “E-Commerce: Convenience Built on a Mountain of Cardboard,” New York Times, February 16, 2016. http://www.nytimes.com/2016/02/16/science/recycling-cardboard-online-shopping-environment.html

[4] “Continuous Recycling | PCA,” Packaging Corporation of America. http://www.packagingcorp.com/continuous-recycling

[5] Corrugated Packaging Alliance, “Corrugated Packaging Life Cycle Assessment Summary Report,” June 2014. http://corrugated.org/upload/2014_Life_Cycle_Assessment_Summary_Report_Final.pdf

[6] “Continuous Recycling | PCA,” Packaging Corporation of America. http://www.packagingcorp.com/continuous-recycling

[7] Corrugated Packaging Alliance, “Corrugated Packaging Life Cycle Assessment Summary Report,” June 2014. http://corrugated.org/upload/2014_Life_Cycle_Assessment_Summary_Report_Final.pdf

[8] Ibid

[9] Packaging Corporation of America, “Form 10-K,” United States Securities and Exchange Commissions, February 26, 2016. https://www.sec.gov/Archives/edgar/data/75677/000007567716000030/pkg1231201510k.htm

[10] Packaging Corporation of America, “Jefferies 2016 Industrials Conference,” August 9, 2016. http://phx.corporate-ir.net/External.File?item=UGFyZW50SUQ9NjQyNzM0fENoaWxkSUQ9MzQ4NDYwfFR5cGU9MQ==&t=1

[11] Ibid

[12] Packaging Corporation of America, “Form 10-K,” United States Securities and Exchange Commissions, February 26, 2016. https://www.sec.gov/Archives/edgar/data/75677/000007567716000030/pkg1231201510k.htm

[13] “Responsible Business Practices | PCA,” Packaging Corporation of America. http://www.packagingcorp.com/continuous-recycling

[14] “Managed Forestry | PCA,” Packaging Corporation of America. http://www.packagingcorp.com/managed-forestry

[15] Packaging Corporation of America, “Form 10-K,” United States Securities and Exchange Commissions, February 26, 2016. https://www.sec.gov/Archives/edgar/data/75677/000007567716000030/pkg1231201510k.htm

Hi – I enjoyed reading your article on the climate change challenges presented by cardboard packaging. As you allude in your article, I feel that people sometimes view 100% cardboard recycling rates as a zero sum game. However, as you point out, there are vast energies expended during the full life cycle of a cardboard box, including carbon emitting reprocessing, burning, and reverse logistics.

Unfortunately, I’m not expecting material changes to come from a company like Packaging Corporation of America (“PCA”). While your list of environmental actions taken by PCA is quite impressive, I feel that the real change has to happen with runaway consumerism. Therefore, I see a greater role being played by fulfillment centers, such as Amazon or Walmart. As these companies increasingly focus on “last mile” delivery, hopefully they will find ways to ship products with less cardboard packaging–or even eliminate it altogether. Would PCA get on “board” with such a no-packaging future, or a future where they swap volume for innovative packaging design (as you promote in your article)? Time will tell…

Hi ijkijk, thanks for the informative read on the cardboard packaging industry. As I look at the two packages delivered to me today, I suddenly feel very guilty.

While I don’t imagine that PCA has the financial incentives to do so, I do think investing in R&D to create alternative packaging is an obvious step the company can take to stay ahead of the industry. As consumers and companies increasingly shift towards a “greener” mindset, it can present huge benefits to the company if their competitive edge is being eco-friendly and cheap. For instance, they could easily look into the many research projects looking into creating packaging materials from agricultural waste that can also compost very quickly.

Additionally, retailers should create awareness about packaging and maybe even incentivize customers to make purchases in a manner that reduces packaging material.

Hi, ijkijk – This is a really interesting and well-researched article – thanks for sharing!

As I read the article, like “DF”, I glanced over at my personal pile of opened packages from this week’s round of deliveries and my heart sank a bit. I like the idea of somehow shifting the burden of sustainable packaging from distributors to consumers. Similar to how various state legislations have mandated the increased use of reusable bags in supermarkets and other local retailers, perhaps a system could be put in place to encourage the use of reusable packaging materials, direct from the consumer.

Yikes! I opened my storage closet only to see a pile of cardboard boxes lying around!

Great article, by the way. With more and more shoppers making purchases online I worry that the situation will only get worse (heck, even some mattresses are being delivered in cardboard boxes). While companies such as Amazon are right-sizing their packaging, it probably is not enough to offset the growing number of cardboard boxes consumed. Nevertheless, the efforts taken by PCA are very commendable.

I look forward to greater R&D effort undertaken in the industry to find innovative solutions in terms of packaging materials and design, that would either replace the materials used to make boxes, or alter the design of boxes to be more efficient and green. It would be great to have a packaging that is made of a by-product (e.g. corn husk, leftovers from cotton) of another industry, as it will reduce its greenhouse warming potential (GWP) substantially.

Marvelously researched and well-written article. I find this type of ‘enlightened capitalism’ to be truly inspiring – with this particular example proving very analogous to IKEA utilizing their massive size, influence and supply chain to support industry trends that not only benefit themselves but also the environment/our planet.

I’m curious to why, in conclusion, you’ve written that PCA should fully commit its sustainability initiative, sourcing 100% of its new fiber through managed forestry et al. Do you believe that this is in the best interest of the firm, the environment, or a mix of both? If only the environment, are there other thoughts you have of how to push the mix more towards the latter (a mix of both) to make this economically and morally responsible?

Hi ijkijk; thanks for the article. To HCL’s comment above, I am one of those that feels very proud when I drop my boxes off in the recycling bin but you raise a good point – that is actually not making a very significant impact on reducing the negative environmental impact of the entire cardboard production process. Thinking back to our IKEA case the other day, which also ultimately included a combination of sustainable forestry and supply chain management, I am quite impressed by the holistic approach PCA has taken across the initiatives you’ve outlined. I’m left wondering what PCA’s version of IKEA’s particle board would be though – a more efficient cardboard alternative could be the next step in their path to sustainability.