Save the planet, drink more beer.

Climate change is brewing problems for crop yields and quality of water, so beer companies are taking matters into their own hands.

Background

Warmer temperatures have caused a reduction in yield of key crops like hop and barley and negatively impacted water, which makes up 90-95% of beer[i]. Researchers suggest that extreme shifts in precipitation patterns have caused droughts, flooding, and reduced snow melts[ii]. Additionally, rising average temperature increases the likelihood of rain over snow and melts snow sooner, changing the streamflow to rivers in regions such as Colorado[iii]. The dependency of quality, quantity, and pricing of ingredients on climate change has led to many Colorado-based brewers taking matters into their own hands.

Company overview

New Belgium is a brewing company that first opened in Fort Collins, Colorado in 1988. From the start, they recognized the significant role climate change would have on their core business of brewing beers. Thankfully, they’ve designed and aligned both their business and operating model accordingly to mitigate these risks. Environmental stewardship is a core value for the company, backed by initiatives within the company and in the greater community. For example, New Belgium created a fund to implement energy efficiency efforts and renewable energy projects based on internally taxing itself on energy consumption. They have also integrated this into their operating model by developing goals tied to quantifiable environmental metrics for water usage, emissions, energy, and waste.

Company initiatives

The good news is climate change also represents an opportunity for New Belgium to benefit from their sustainability efforts. While large capital expenditures may be required upfront, there are both long-term financial and intangible benefits. A few past initiatives include:

- Built an 225,000-gallon on-site water treatment plant for $12M in order to capture the methane produced to generate renewable electricity and heat in a combined heat and power system. As of 2015, about 20% of annual electricity is generated onsite resulting in annual savings of around $130,000[iv]. Additional solar-panels have been installed as well.

- Reduced total waste sent to landfills by having over 500 waste collection points available throughout the brewery and enforcing waste auditing. In 2015, New Belgium decreased waste to landfill down to 54g per hectoliter packaged, which was their 2018 goal.

- On-going support for philanthropy and advocacy partnerships. New Belgium has donated over $8M to charitable organizations and is active in 10 advocacy groups to promote environmentally and socially responsible policies. As a result, New Belgium is able to garner good will and support from communities, including participation in events only selling New Belgium beers. (Value of brand loyalty: priceless?)

Aligning incentives

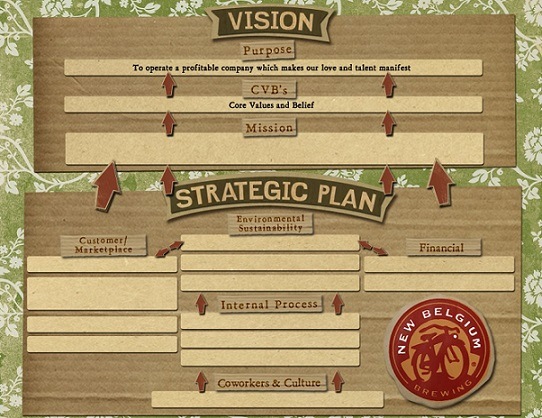

Sustainability is used as a key factor in decision-making processes for strategic alignment[v]. Each decision is made to have policies aligned with their mission of creating environmental stability, which is interdependent with financials and customers. As a result, New Belgium is able to match the incentives for advocating environmental sustainability and selling more beer. For instance, due to the increase in demand and decrease in yield, hops have increased in price over 250% in the past decade[vi]. It is in New Belgium’s best interest to make hop production sustainable and increase the yield to decrease cost of goods sold.

Given climate change pressures, New Belgium acknowledged the need to diversify dependence on natural resources from one region. This past summer, a second brewery opened in Asheville, North Carolina. Instead of cutting upfront costs for PP&E, New Belgium stayed true to their sustainability values and built it as a LEED-certified brewery. Having this second brewery in a distinct location provided New Belgium access to another clean water source, which helps ensure the taste and quality of their beer is driving top line sales.

Looking ahead

Moving forward, they should continue to innovate and invest in R&D to promote sustainability efforts internally. This should not only identify new equipment that is more energy efficient but also more eco-friendly process (e.g., develop a new process for dry hopping that requires less water). It’s in New Belgium’s best interest to remove their dependency on externally energy and resources as much as possible. This would help shield them from future fluctuations in input costs and quality so that they can have as much control as possible over the output. New Belgium should also take partnerships one step further and actually work with other beer companies to reduce industry impact on climate change. They could collectively sponsor or subsidize energy-efficient equipment for other breweries to adopt environmentally friendly operations. The entire brewing industry benefits when there impacts of climate change are reduced to minimize variability for production.

With a double bottom line that aligns their operating model with their community values, New Belgium has in essence turned being environmentally sustainable into a competitive advantage.

Word count: 766

Sources:

[i] USGCRP (2014). Georgakakos, A., P. Fleming, M. Dettinger, C. Peters-Lidard, Terese (T.C.) Richmond, K. Reckhow, K. White, and D. Yates. Ch. 3: Water Resources. Climate Change Impacts in the United States: The Third National Climate Assessment, J. M. Melillo, Terese (T.C.) Richmond, and G. W. Yohe, Eds., U.S. Global Change Research Program, 69-112.

[ii] National Centers for Environmental Information, “Climate and historical weather data and information,” http://www.ncdc.noaa.gov/, accessed November 2016.

[iii] EPA, “Climate Impacts Water Resources,” https://www.epa.gov/climate-impacts/climate-impacts-water-resources#ref1, accessed November 2016.

[iv] Southwest CHP Technical Assistance Partnership, “New Belgium Project Profile,” http://www.southwestchptap.org/data/sites/1/documents/profiles/New_Belgium-Project_Profile.pdf, accessed November 2016.

[v] New Belgium, “Strategic alignment,” http://www.newbelgium.com/Sustainability/Environmental-Metrics/strategic-alignment, accessed November 2016.

[vi] United States Department of Agriculture, “Hop Stocks,” http://usda.mannlib.cornell.edu/MannUsda, accessed November 2016.

I think New Belgium represents a great example of business that has reached a certain threshold of scale where they can actually work to improve energy efficient, best practices for the broader industry. The primary question this raises for me is what the increased price of raw materials will have on the fast growth of micro-brewing and whether this trend will be massively curbed by a higher entry cost for the market. In turn, will we see a greater degree of consolidation in the industry when building high efficiency breweries and distribution methods comes at a much higher upfront cost.

It will be interesting to see how the major players in the beer industry adapt to climate change – in particular Anheuser Busch and Miller Coors. These companies operate massive facilities and use incredible amounts of water and energy (not only for production but for worldwide distribution as well). I hope these companies are learning from the willingness of smaller companies like New Belgium to make capital investments and engage in other initiatives that promote sustainable business practices, as I think that the bigger companies have the potential to drive industry technology down more sustainable paths.

You had me with the title. I recently visited the Lagunitas brewery in Northern California and they had sustainability and emissions reduction initiatives similar to New Belgium ones described in your article.

What strikes me is how, in the craft beer industry, there is a convenient alignment of sustainability and cost savings. The water recycling and methane recycling projects mentioned in your article do good for the environment, appeal to consumers, and lead to cost savings. If there’s any lessons here, it’s that good businesses explore the overlap between social/environmental good and supply chain cost reductions.

I love New Belgium! It’s interesting to see that New Belgium is 100% employee owned. If the company was owned by private equity or public investors, I wonder if it would still be able to commit to such large capital expenditures with extremely long payback periods for the purpose of sustainability.

I hope that major players in the beer industry can work together to figure out lower cost ways to replace existing machinery with more energy-efficient technology. I think there is also potential for the government to create subsidized debt instruments targeted towards helping companies investing in more energy-efficient technology that require large capital expenditures. Government subsidies for consumers buying electric vehicles has been extremely successful, and they should consider similar concepts for B2B capital expenditures.

It’s awesome to see New Belgium taking a leading role in sustainable growing/brewing practices. With all of the micro-brews in Asheville, it’s another great opportunity for New Belgium to influence others at a grass roots level.

I wonder if the beer industry as a whole should be making an even stronger shift to canning its beers. I feel like it’s a more efficient way to package beer and results in less beer lost during the shipping process.

Great post! I am New Belgium fan. Not only because its great beers, also because how they have positioned their brand. I found very interesting the fact that they have donated $8M to charitable organizations. Even though I imagine the recipients of those funds have been able to fund interesting projects, I am worried that this $8M are a mere PR stunt. In my professional experience, I have seen how in most cases it is better to use funds in fewer bigger projects than in more of smaller ones. I would recommend New Belgium to keep investing in on-site water treatment plants and/or landfill collection points. In the long run, these type of investments, if advertised properly, will be rewarded by end-consumers.

Thanks for this post – I had no idea that New Belgium took its commitment to environmental conservatism so seriously! Even more so than what we debated about Ikea’s “green” practices in class, New Belgium really does seem to be walking the talk. This might be difficult to do given its size as a microbrewery, but I wonder if the company can take an even bigger, more mainstream role in advocating for sustainability in the beer-making industry. At brewing competitions or tradeshows – attended by beer companies of various sizes – they could host (or sponsor) a panel on sustainability and discuss the reasons and benefits behind their new LEED-certified building. Additionally, given that they already make great beer (love Fat Tire!), New Belgium could create a competition for “best tasting environmentally-friendly beer” to be held each year; perhaps more of their competitors would be incentivized to adopt green brewing practices if there is a prestigious (even just reputationally) prize to compete for.

Thanks for the post – I am a huge New Belgium fan so found this to be very relevant. It sounds like New Belgium has taken the opportunity to actually invest real dollars into becoming a more environmentally friendly company. I really enjoyed learning about all the new initiatives they have undertaken. I have to wonder though if New Belguim is able to undertake these because of the fact that they are private. If they were publicly traded or private equity backed, would they have been able to have the same flexibility or lead way in pursuing these types of investments. Is that the reason why larger companies like AB InBev have not really undertaken similar measures yet?

I think New Belgium should consider increasing their advertising spending in order to better educate the consumer on these types of projects. I buy New Belgium because of the taste and had no idea they were on the forefront of tackling climate change in the beer industry. I am particularly impressed as I am sure countless other consumers would be as well.