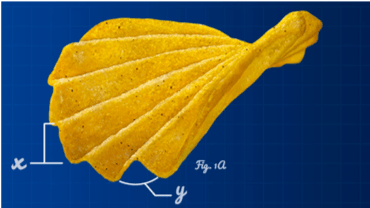

RIDGES Run Deep: How PepsiCo Delivered on Crunch through 3D Printing

PepsiCo employed 3D printing to create the RUFFLES Deep Ridged masterpiece. Under Nooyi's leadership, the corporation greatly expanded its innovation capabilities; however, other innovation programs may be superseding additive manufacturing at PepsiCo.

In 2012, the PepsiCo R&D team aimed to deliver on a consumer insight: RUFFLES’ target demographic, men ages 18-34,[i] wanted a “heartier”[ii] chip.[1], [iii] Director of PepsiCo Frito-Lay North America R&D, Keith Barber, articulated the challenge: “‘…how do we design a heartier chip, while keeping it thin?’”[iv]

Prototyping with 3D printing enabled the team to get quick focus group feedback on the concept and determine whether to invest more time and resources into the design. 3D printing facilitated the development of the chip and the introduction of a new source of revenue: “‘patents on the design, the cutter, the mouth experience.’”[viii]

Today, consumer goods companies need 3D printing in order to rapidly prototype to meet evolving consumer tastes, capture trends, compete against established rivals, and protect against startups (who innovate in small batches, incurring minimal costs and turnaround times).

As for how PepsiCo will address 3D printing in the future, longtime (and recently departed) CEO Indra Nooyi doubled the R&D budget.[ix] She also hired 3M’s head of design, Mauro Porcini as Chief Design Officer[x] and he now oversees the SoHo Design & Innovation Center.[xi] While this could be a hopeful sign for PepsiCo’s future additive manufacturing capabilities, it is unclear what mediums the design team uses.[xii]

Regardless, PepsiCo could improve the adoption of additive manufacturing by training their packaging and brand design experts in 3D printing. 3D prototypes should be used in consumer research as a better form of stimuli (vs. 2D printouts). And, while in the RUFFLES case they printed plastic, PepsiCo should consider how new technologies in 3D printing may enable them to produce edible prototypes.

PepsiCo’s organizational design raises questions. In addition to Porcini’s SoHo office, innovation teams are split across function (marketing, design, e-commerce, digital) and category (hydration, fruit & veg, e.g.).[xviii] Is this division of innovation across units hindering adoption of additive manufacturing?

And, with regards to manufacturing, can PepsiCo create and/or ascertain flexibility in its production line to accommodate special edition packaging? For example, can a batch of 250 3D printed cans fit into the production line without incurring switchover costs?

(Word Count: 798)

FOOTNOTES

[1] While women liked the “light and airy” nature of Lay’s chips, men were looking for a chip with “thick ridges, [that] is filling and offers a harder bite.’” Functionally, research showed that men were also looking for a chip that could “‘absorb the alcohol’” but not dampen “‘their buzz.’” [iii]

[2] PepsiCo Packaging Engineer Andrew Phinney spoke about the Brisk/Black Panther partnership at TCT Show 2018, but did not speak on any internal additive manufacturing efforts. [xix]

ENDNOTES/WORKS CITED

[i] PepsiCo, “Ruffles launches Ultimate Chips and Dips, offers first taste at MAXIM’s ‘ultimate party,’” May 17, 2012, http://www.pepsico.com/live/story/ruffles-launches-ultimate-chips-and-dips-offers-first-taste-at-maxims-ultimate-p05172012524, accessed November 2018.

[ii] Daily Beast, “The Innovation Behind the Crunch Enjoyed Around the World,” https://www.thedailybeast.com/the-innovation-behind-the-crunch-enjoyed-around-the-world, accessed November 2018.

[iii, iv, v, vi] E. J. Schultz, “How the Women Running RUFFLES Unscrambled the ‘Bro Code,’” AdAge, June 2, 2013, https://adage.com/article/news/women-running-ruffles-unscrambled-bro-code/241821/, access November 2018.

[vii] PepsiCo, “The Making of RUFFLES® Deep Ridged Potato Chips in 6 GIFs,” May 12, 2015, http://www.pepsico.com/live/story/the-making-of-ruffles-deep-ridged-potato-chips-in-6-gifs, accessed November 2018.

[viii, x, xiv] Jennifer Reingold, “PepsiCo’s CEO Was Right. Now What?” Fortune, June 5, 2015, http://fortune.com/2015/06/05/pepsico-ceo-indra-nooyi/, accessed November 2018.

[ix] Benjamin Snyder, “This potato chip has a surprisingly futuristic backstory,” Fortune, June 6, 2015, http://fortune.com/2015/06/06/pepsi-chip-3d/, accessed November 2018.

[xi] PepsiCo, “Headquarters,” http://design.pepsico.com/contacts.php?v=73, accessed November 2018.

[xii] PepsiCo, http://design.pepsico.com/stories.php?v=73, accessed November 2018.

[xiii, xvii] Protolabs, “PepsiCo R&D Team Elevates Packaging Design with 3D Printing,” https://www.protolabs.com/resources/case-studies/pepsico/, accessed November 2018.

[xiv] Jennifer Reingold, “PepsiCo’s CEO Was Right. Now What?” Fortune, June 5, 2015, http://fortune.com/2015/06/05/pepsico-ceo-indra-nooyi/, accessed November 2018.

[xv] Brett Dworski, “New PepsiCo Platform to Develop Emerging Brands,” CSP Daily News, August 22, 2018, https://www.cspdailynews.com/snacks-candy/new-pepsico-platform-develop-emerging-brands, accessed November 2018.

[xvi] LinkedIn, Jim Watson, https://www.linkedin.com/in/jim-watson-b6ba9078/, accessed November 2018.

[xviii] LinkedIn, accessed November 2018.

[xix] Laura Griffiths, “TCT Show 2018: Airbus, PepsiCo and BMW to deliver additive manufacturing insights,” TCT Magazine, September 17, 2018, https://www.tctmagazine.com/tct-events/tct-show-uk/tct-show-2018-airbus-pepsi-bmw-additive-manufacturing-conference/, accessed November 2018.

[xx] (Cover Photo) Dan Souza, “We Try the New Ruffles Ultimate Chips ‘For Men,'” Serious Eats, https://www.seriouseats.com/2012/11/ruffles-ultimate-chips-new-for-men-flavors.html, accessed November 2018.

Very surprising to learn that 3-D printing was used to improve potato chips! I admit that this seems to me to be a strange use of R&D spend for Pepsi. There is so much happening in the food system – protein alternatives like clean meat/plant-based meat, more effective sugar – that I would have thought that Pepsi would be more focused on larger breakthrough ideas. But this convinced me that new technologies could still be used to improve core “boring” products.

This is a strange application of 3D printing, and the cynical part of me wants to argue that it’s more of a PR stunt than a process improvement. For a product like potato chips, so much of the value comes from taste, texture, and packaging, none of which can be reproduced with a 3D printed prototype. The prototype chip only serves as a proxy for the final product’s shape, so I’m skeptical of the marginal benefit this achieves over a 2D rendering. Other industries like manufacturing or technology rely on 3D printing because their product development cycles need to be short in order to stay ahead of the competition and because the finished product is much more costly to produce than the prototype. Neither of these ring true for potato chips. I wonder if the investment in 3D printing is more of a strategic move for PepsiCo to jump on the bandwagon of buzz-worthy trends.

I loved the quote about what men were looking for — I didn’t realize a different potato chip design could help absorb more alcohol!

While I agree that 3D printing allows PepsiCo to test out new product designs in a more efficient manner, I can’t help but wonder if it’s a cost effective investment. It could also appear to be a distraction, since plastic ridge chips can’t be eaten and physical potato chips cannot be printed (yet). I think utilizing 3D printing for new packaging designs is a great application of additive manufacturing, but I am skeptical on the benefits of food designs at this stage.

This is a fun use-case of 3D printing! It’s exciting that PepsiCo is looking to challenge their own status quo through the creation of their SoHo Design & Innovation Center and through The Hive incubator and the Shark Tank style program, however it seems that there may be a need to tie this “innovation mindset” more deeply into the established product development processes. As you raise above, their organization seems to be a bit disjointed and nascent in its use of the technology, and it seems that there is a huge opportunity that still exists to leverage the technology to (hopefully) create a sustainable advantage in this hyper-competitive space. I would be interested to see how (and if) PepsiCo can take this one step further – from rapid prototyping, to more permanent integration into production and design processes.

Great read!!! Your article raised a lot of questions.

I wonder how 3D-printing can impact the consumer value proposition of products beyond the shape. Could it provide a benefit in the ways the ingredients are combined/layered?

I also wonder how quickly consumers will become comfortable with 3D-printing. I would expect the barrier to be low, so should some agriculture producers be thinking about their processes in light of the trend? This hinges a bit on the scale 3D-printed food can achieve, which as someone aptly mentions above is likely limited given the costs.

This was a very interesting use of 3D printing. I never would have thought 3D printing would be applied to potato chips.

I think this application is interesting because it enables Pepsico to print a potato chip in the exact shape they want. Maybe they can do a consumer study to create the “perfect potato chip shape” that maximizes the consumer delight. However, one thing that comes to mind would the perceived notion from the consumers if all of the potato chips look identical. I think the consumers would perceive identical chips as not natural and synthetic.

Very unique application of 3D printing towards food! In light of Pepsi’s new mission to cater more towards healthier alternatives (Good for You, Better for You, Fun for You), this is an opportunity for the company to produce healthier versions of products that would otherwise not be possible with traditional manufacturing. I’m slightly wary of 3D printing towards food given the move towards farm to table and organic, as it goes down the route similar to Genetically Modified Food.

Really fascinating article. It was interesting to read how using 3D printing, Pepsico could design the shape of the chip. This is an important design feature as it helps to reduce the weight and ultimately the cost of product (production, packaging and transportation) while delivering the taste benefits as per the consumers demand. However, I am skeptical of the scale that this can be used on beyond just designing the “perfect chip shape” and think there may be more interesting ways in which pepsi could have used 3Dprinting.

Very interesting! I think your question on organizational design is extremely relevant and it applies across organizations who are beginning to use new technologies (machine learning included). As new processes develop to change how we prototype, how we produce, or how we analyze data across functionalities, organizations need to be rethinking how their organizational design needs to shift to adapt to new needs. It is likely that, as mentioned, organizations are beginning to build divisions of innovation across units. However, as these processes become more entrenched in day to day processes there will likely be a need to have 3D printing experts imbedded within units as opposed to having an ad-hoc team.