McMaster-Carr & 3D Printing: What Happens When Your Product is Digitized

How should McMaster-Carr, a beloved fastener manufacturer and distributor, react as their core product can be easily printed by their consumers within 5 years time?

3D printing threatens to disrupt current supply chains through the digitalization of the product. Companies that manufacture and deliver small and simple products will find their customers printing their products instead of traveling to the stores or holding large amounts of inventory. McMaster-Carr, a beloved brand in engineering and maintenance, may be one of the first victims.

3D Printing

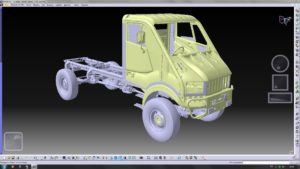

For an introduction to 3D printing, check this video. [1] Simply, a user builds or downloads an STL (stereolighography) file, makes minor adjustments if necessary, uploads the file to their personal 3D printer, and waits for the printer to print the object [1]. 3D printers can work with multiple types of plastic, wood and metal filaments [2]. This process can take 15 minutes for small parts, or 24 hours for large complicated objects. Currently, 3D printing is mostly confined to hobbyists and prototyping as the technology is not quite cheap and reliable enough to make production-grade materials. However, 3D printing is expected to be a $32.78 Billion industry within five years as the technology improves and companies begin adopting the tool for rapid prototyping, production and maintenance [3].

McMaster-Carr and the Current Supply Chain

McMaster-Carr is an MRO (Maintenance, Repair and Operations) company that specializes in selling fasteners (screws, nuts, bolts) [4]. Their no-nonsense website design and fantastic service have made them the go-to order location for a company, factory or hobbyist needing parts from McMaster-Carr’s 550,000 SKUs. By focusing on key services like CAD models, custom-part creation and same day delivery, McMaster-Carr has been able to set themselves apart from the competition [5].

Factories and engineering firms will normally keep a safety stock of key fasteners. Even though each fastener takes up little space, there can be thousands of different fasteners that are needed in a company or project. [4] This means the safety stock held by the end customer can be quite large, taking up key space in the factory or office. In industries with major space constraints, this inventory space can prove to be costly [4].

How 3D Printing Effects McMaster-Carr

3D Printing has the potential to disrupt McMaster-Carr’s core business model by promising lower inventory cost and shorter lead times. When 3D printing becomes reliable enough, businesses will begin simply printing the fasteners they need rather than holding a safety stock or paying for shipping. By switching to a Just-In-Time model, companies will lower their inventory holding cost and effectively increase the workable area of the company. The digitalization of the product will eliminate the need for a manufacturer or a deliverer, as businesses can manufacture their own parts just-in-time. While there may be a need for more durable fasteners for high-end goods, the total revenue for McMaster-Carr will fall.

McMaster-Carr is already responding to this incoming threat to their business model [4]. Currently, McMaster-Carr offers STL files for certain parts for free to be downloaded from their website. In addition, the CAD models McMaster-Carr provides with each order can be converted into an STL file. The idea is to allow the user to test out a part before ordering a durable and reliable version. McMaster-Carr is already training consumers that their website can be a location for high-quality STL files [6].

The Path Forward

As McMaster-Carr is a private company, their plans are not public. Based on their current actions and offerings [4], however, I believe their plan is to begin selling high-profile STL files directly from their website within the next 3 years. However, I would guess that within 10 years McMaster-Carr will double-down on the high-profile part business and let the lower-margin business fall to 3D printing [4].

McMaster-Carr’s brand equity does allow them to react in a more profitable manner. In the short term, they should keep offering the STL files online and eventually the more complicated ones for individual purchase. For longer term, McMaster-Carr should partner with a 3D printing company and set up the ability to remotely upload STL files. In addition, they should set up an STL file database with the infrastructure to become the “Netflix of Fasteners”. By offering a subscription model to their STL file database, a consumer can choose the product they want and have it start printing immediately. McMaster-Carr can then offer high-quality services such as file customization and 3D printing consulting. This plan leverages McMaster-Carr’s fantastic brand equity and allows them to pivot to the next generation.

My primary fear with this approach are open-source STL files. While McMaster-Carr may be able to have service and higher-quality files, the STL files online will be free. Hobbyists will probably switch over to open-source files, but will prototyping engineering firms? How does McMaster-Carr avoid losing too much market share to the open source world?

In addition, is there a way for McMaster-Carr to embrace 3D printing on their personal manufacturing side and lower costs there? Thus far I’ve focused on the end customer, but can McMaster-Carr leverage 3D printing to a better effect?

(799 words)

[1] 3D Now, “The Ultimate Beginner’s Guide to 3D Printing,” YouTube, published March 10, 2017. [https://www.youtube.com/watch?v=3LBTkLsjHGQ], accessed November 2017

[2] David Bak, “Rapid prototyping or rapid production? 3D printing processes move industry towards the latter.” Assembly Automation Vol 23 Issue 4 (2003): 340-345

[3] marketsandmarkets.com, “3D Printing Market by Offering (Printer, Material, Software, Service), Process (Blinder Jetting, Direct Energy Deposition, Material Extrusion, Material Jetting, Powder Bed Fusion), Application, Vertical and Geography – Global Forecast to 2023,” Top Market Reports (July 2017), Market and Markets.com. http://www.marketsandmarkets.com/Market-Reports/3d-printing-market-1276.html, accessed November 2017

[4] Interview with Joseph McKenna, former McMaster-Carr operations employee, November 11, 2017.

[5] Hackaday, “A Noob’s Guide to McMaster-Carr,” https://hackaday.com/2017/09/13/noobs-guide-to-mcmaster-carr/, accessed November 2017

[6] Make:, “Pro Tip: You Can 3D Print Parts from McMaster-Carr,” https://makezine.com/2015/02/06/pro-tip-you-can-3d-print-parts-from-mcmaster-carr/, accessed November 2017

How is McMaster-Carr thinking about 3D printing with metal (not plastic)? The technology is still too expensive for much scale.

Dan – this is a great article! you do a great job of summarizing the effects and potential future implications of 3D printing. While it seems like McMaster-Carr is being proactive in incorporating STL files onto their website, I am skeptical that they will be able to survive in the long run once companies in the future print their own parts (as the cost and need for expertise declines), bypassing suppliers completely. One article suggests that “47% of companies that buy spare parts have been looking into using 3D printing to create their own parts” because their needs are not currently adequately being met by suppliers [1]. The current lack of widespread expertise in 3D printing and technical maturity suggests McMaster-Carr will still remain relevant/competitive for at least the short-term. I am interested to see how McMaster-Carr continues to evolve its core competencies in reaction to 3D printing. I wonder whether 3D printing will actually take hold or whether it will remain relegated to the small, spare parts.

[1] https://www.strategyand.pwc.com/media/file/The-future-of-spare-parts-is-3D.pdf

Thanks for an interesting post!

Reading this, I believe that 3D printing offers an exciting technological alternative. However, I wonder about the potential for 3D printing to scale up in a cost effective way when McMaster-Carr provides so many value-added services. There are a few areas that I think will decide who wins in the debate between old and new technology:

1) Footprint: One rationale for 3D printing is that it saves space that would otherwise be taken up by inventory. Given the small size of fasteners, I wonder how this inventory space compares to the space required for the number of 3D printers that would be needed to support large and continuously operating manufacturing plants.

2) Speed: Your post stated that 3D printers currently take 15 minutes at a minimum to produce one small part. When McMaster-Carr offers same-day delivery, I wonder which of the two options really provides more of a “just-in-time” solution. It seems that unless speeds improve, manufacturing companies would be better off sourcing the exact types of fasteners they need each day from McMaster-Carr rather than timing their entire operation to the cycle time of the 3D printer.

Both of these points also make me question whether the right segment for McMaster-Carr to focus on is highly customized fasteners as suggested by the post. If 3D printing remains costly and slow, it may be better for in-house production of highly customized but rarely ordered parts that are inefficient to keep in inventory. Meanwhile, McMaster-Carr could continue its daily delivery of mass parts that require low labor content and can be produced quickly.