L.L. Bean: It Pays to be a Contrarian

What happens when IDEO Design Thinking meets a Vertically Integrated Supply Chain meets a No-Holds-Barred Customer Satisfaction Policy? Simple. Meet L.L. Bean.

Business Model

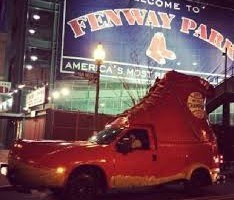

L.L. Bean is an outdoor gear and apparel merchant whose mission is to inspire youth and families to engage in outdoor recreational activities. With $1.6B in net revenue split among catalog, e-commerce, and brick-and-mortar sales channels all experiencing year-over-year growth, one might say they’ve succeeded. From its modest beginnings in 1912 when founder Leon Leonwood Bean sold his signature, hand-crafted boots out of one room, until present day, L.L. Bean has always stood behind the same value principles: a focus on the customer, continuous product improvement and innovation, and a 100% satisfaction guarantee. L.L. Bean has delivered on its customer promise through operations that involve Design Thinking, Supply Chain Management, and exemplary Customer Service.

Operating Model

Design Thinking

https://www.youtube.com/watch?v=mHiltxEmi3k

When it comes to innovation, IDEO has demonstrated that it pays to interact with the heaviest users of products for idea generation purposes. L.L. Bean has taken that concept a step further by partnering with elite athletes like Seth Wescott who not only ideate innovative concepts but also test prototypes in extreme situations that will guarantee functionality and durability for the mass market. L.L. Bean complements this experiential testing with scientific analysis of materials, construction, and design in its own independent lab.

As many brick-and-mortar retailers have scrambled in recent years to build out e-commerce platforms, L.L. Bean’s established e-commerce presence has allowed it to go the other way. Sometimes it pays to be a contrarian. The “Outdoor Discovery Schools” in the above video are run out of every retail store and are more than just a prime opportunity to increase brand visibility and demonstrate the quality of L.L. Bean products. From a design thinking perspective, the Schools are an ingenious way to organically create customer focus groups. School attendees are more than happy to unwittingly serve as sources of feedback on products while snowshoeing, kayaking, and paddleboarding.

Supply Chain Management

L.L. Bean has a history of leveraging data analytics to streamline its supply chain. In 2007, its distribution network was approaching capacity. Excess seasonal inventory had been crowding shelves. Instead of investing in a new distribution center, they invested in inventory management systems to increase throughput. Aligning inventory policy to customer demand meant separating SKUs into “core” and “non-core” items. Core items experienced consistent demand regardless of the time of year while non-core items experienced seasonal demand. L.L. Bean responded by developing product-specific inventory lifecycles for its seasonal items.

Inventory characteristics also differed by sales channel. As a result, L.L. Bean split its two distribution centers, both in Freeport, Maine, into a retail distribution center and a catalog/online sales distribution center, optimizing for both. Doing so has empowered the retail channel to own its inventory management through improved forecasting and sourcing product to stores.

Completing the vertical integration of its supply chain, L.L. Bean tightly couples its distribution centers with its manufacturers and suppliers. The company-owned manufacturing facilities are located a stone’s throw from Freeport in Brunswick and Lewiston, Maine. Core items, such as boots and tote bags, are still made in those facilities. Non-core items are received in small, frequent batches from suppliers. Sales transparency with suppliers has obviated the need to engage in the guesswork involved in ordering large quantities of non-core items for an entire season.

A better understanding of product lifecycles, the channel-specific distribution centers, and the just-in-time relationship with suppliers has led to less overstock of seasonal inventory, more of the products customers buy all year long, and a reduction in warehousing costs.

Customer Service

https://www.youtube.com/watch?v=6buiEQQ27XA

L.L. Bean’s Customer Satisfaction department operates out of 3 customer service centers in Maine, 24 hours a day, 365 days a year. Problem? Customer representatives are practically on the site of operations to fix it, not in an international call center.

In their words, “our guarantee is based on something as simple as a handshake – the deal that you’ll be satisfied with your purchase, and if you’re not, we’ll make it right.” If a customer does not have a receipt, L.L. Bean will do its best to locate a record of the purchase. If unsuccessful, L.L. Bean reimburses the customer with a gift card. Even if a product was customized, embroidered, or monogrammed, a customer can still return it at any time. Customers and employees alike know they are in safe hands with L.L. Bean. The company regularly wins awards for customer loyalty and customer service.

—

This past year, L.L. Bean made a $78.5M investment to both fully fund its defined benefit pension plan and pay 8% bonuses to its 5,000 permanent employees. Though the financial information for this private company is unavailable, these actions speak volumes to L.L. Bean’s profitability and what can be accomplished when business and operating models are aligned.

Sources:

http://www.llbean.com/customerService/aboutLLBean/company_information.html

http://www.supplychainquarterly.com/topics/Strategy/201104llbean/

http://www.llbean.com/llb/shop/510624?bvCategory=510624&nav=ftlink

https://www.llbean.com/customerService/aboutLLBean/images/FactSheet_2015.pdf

I’ve always found LL Bean to have such an interesting story. They seem to have survived the rush of new companies into the outdoors / fitness market with a steady business model that has stayed true to its core tenants. I haven’t seen their product change much over the years, in fact, not at all among their best sellers. This is pretty impressive considering the market has evolved so much, but I guess that is what happens when you have such a superior product quality. People will always come. Also something to note, their customer service is incredible – almost too forgiving (I know someone who returned boots 3 years after wearing them ~100 days every winter season because they were falling apart, and without hesitation, LL Bean sent a new pair!). It does make for loyal customers, but at what point is “too much” customer service that puts a strain on bottom line?

My favorite neighbor! I can definitely appreciate the point about superior quality. The other side of the coin to quality is price. Consumers make purchases when the perceived quality more than justifies the asking price. This is certainly true of L.L. Bean products and touches on the first of five standard objections in every sales process (from The Personal MBA by Josh Kaufman):

1) Loss Aversion: It costs too much. Makes spending feel like a loss.

2) It won’t work.

3) It won’t work for me.

4) I can wait.

5) It’s too difficult.

—

L.L. Bean overcomes each of these objections through its pricing strategy, quality, and/or customer service.

– Objection (1) is dealt with because perceived quality > price.

– Objections (2) and (3) are usually addressed via Social Proof. L.L. Bean’s exploding popularity on social networking sites like Pinterest in the last 3 years checks that box.

– Objection (4) is best dealt with by educating the customer on why they need what you’re selling, and L.L. Bean’s Outdoor Discovery Schools are an opportune forum during which to do so.

– Objection (5) is best dealt with via “Risk Reversal” – transferring the risk of purchase from the buyer to the seller – thereby reducing the final “Barrier to Purchase.” This is where L.L. Bean’s customer service and highly accommodating return policy comes into play. Your final question about when does customer service essentially become “too” accommodating to the point where the bottom line is adversely affected is a logical one. However, I think in an age where everyone is hypervigilant for the asterisk at the end of company guarantees, L.L. Bean is wise to maintain its customer service policy to perpetuate trust in the Risk Reversal they offer to consumers.

I’m fascinated by the return of Bean Boots – these iconic boots are in such high demand lately, and I’m not convinced that L.L. Bean is handling its spike in popularity all that well. A few years ago, I made the mistake of waiting until November to order my boots in preparation for New England winter and ended up getting them in April. It seems like the company has yet to solve this problem – 100,000 Bean Boots were backordered last winter according to the article below. Manufacturing hand-sewn boots is a labor-intensive process, and this has helped the company develop a reputation for high-quality. I wonder whether L.L. Bean will be able to scale its manufacturing to keep up with its demand, and I question the company’s ability to forecast demand and manage inventory levels.

http://www.bloomberg.com/news/articles/2015-09-29/why-can-t-l-l-bean-keep-the-darn-duck-boots-in-stock-

Forecasting demand is inherently inexact, but L.L. Bean did alleviate its 2007 seasonal inventory overstock problem after their investment in inventory management. Supply had been outstripping demand for those seasonal items, and that is no longer the case. The question becomes has the pendulum swung back too far the other way. As you point out, demand has outweighed supply for its iconic boots over recent years. It is interesting to note that, after existing for decades with predictable purchase patterns, its boots experienced an uncharacteristic spike in demand (>57% in 1 year’s time) after exploding in popularity on social networking websites like Pinterest. That “spike” has yet to subside. The company has responded by flexing its labor policies during the holiday months when they essentially double their manufacturing employee base. Point being, no company will ever forecast demand perfectly, and it would have been impossible to predict the boots’ surging popularity in advance. The company will need to look into how they can scale manufacturing this labor-intensive product if demand continues to outweigh supply, which as you say, will not be easy. However, at least their separation of inventory into “core” and “non-core” pools isolates the problem.

REI and LLBean had similar customer service “return anything anytime” policies, but REI recently shifted toward a one-year (vs lifetime) guarantee. I think the customer service piece is definitely key to LLBean’s operating model, as you write, and their Marketing VP also explains that it serves as some pretty great free advertising. What I’d like to understand is if and how they attempt to capture the value their customer service policies create, and how that compares to what competitors might be spending on traditional advertising.

http://www.npr.org/sections/money/2013/09/25/223787129/what-happens-when-a-store-lets-customers-return-whatever-they-want