Is Child Labour the Only Way Forward for Tesla?

What options are left for Tesla in the ethical sourcing for its rechargeable batteries?

Can Tesla continue its mission to accelerate the world’s transition to sustainable energy[1] without relying on child labour? It’s a question that concerns the supply chain of a raw material that underpins Tesla’s plans to scale renewable energy and electric vehicles (EVs)[2], and one that doesn’t have an immediately obvious answer.

To limit the effects of climate change, governments around the world are introducing policies to shift the world’s supply of energy to renewable sources[3]. Right now, solar and wind are the cheapest sources of renewable energy[4]. To fully replace fossil fuels, though, their energy needs to be stored so that households and industry can still consume power whilst there isn’t much sunshine or wind[5]. As the technology of lithium-ion batteries improves, large-scale storage is becoming more economically feasible[6]. Energy utility companies are responding to policies such as the US’s production tax credits[7] by building increasingly more lithium-ion batteries on an increasingly large scale. The battery that Tesla is constructing in South Australia, for example, is three times larger than the world’s biggest current storage facility[8].

As Tesla’s product mix shifts towards lithium-ion batteries, so too does its reliance on one of lithium-ion batteries’ key ingredients: cobalt. This is of major concern to Elon Musk and his executive team for a number of reasons:

- Cobalt prices will sky rocket as batteries become even more economical and government policies further promote the installation of renewable energy and storage solutions – the price of cobalt has more than doubled in just the last year.[9]

- There isn’t enough cobalt being mined to meet the projected increase in demand of EV and utility-scale batteries, period.[10]

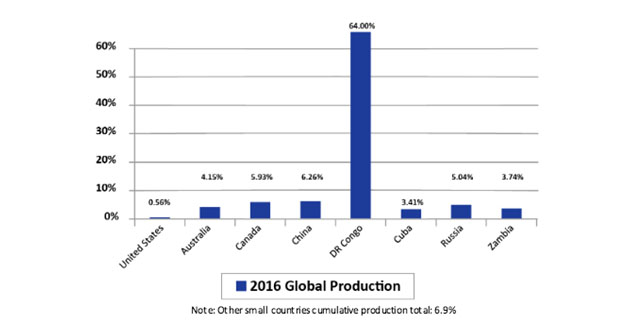

- With more than 60% of the world’s cobalt being supplied by the politically unstable Democratic Republic of Congo[11], current supply of cobalt is also perilously unstable[12].

- An estimated 40,000 children are working in the DRC’s cobalt mines, in hazardous conditions.[14]

Tesla has already taken actions to address some of the issues surrounding its supply of cobalt.

In the short term, Tesla and its suppliers have bought up reserves of cobalt in response to recent surges in its price (largely due to stockpiling by hedge funds)[15]. This is not a durable solution to what is a long-term problem, however, and Tesla will need to find a way of ensuring a long-term supply of cobalt at prices that don’t make their EVs or utility-scale batteries uneconomical to the consumer.

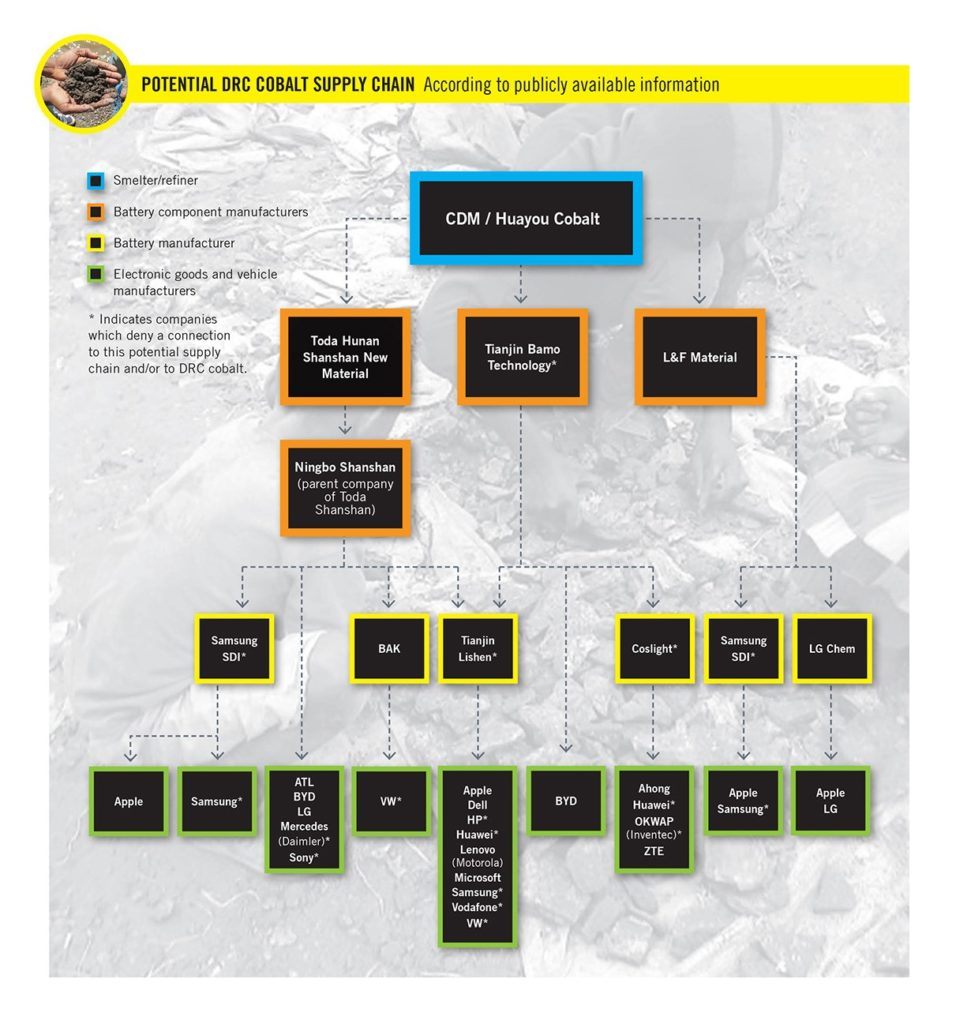

In the medium term, Tesla has committed to using only cobalt sourced from North America[16]. It has so far been successful, and avoided being named in a report by Amnesty International linking EV manufacturers such as Volkswagen, Mercedes and GM to human rights abuses in the DRC regarding the global trade in cobalt[17].

Whilst Tesla’s success in this regard to date is admirable, it may, however, be short-lived. In 2018, more than 40% of the world’s cobalt production is forecasted to be used to make rechargeable batteries[19], and it is estimated that in 2018 Tesla will produce more than half the world’s rechargeable batteries[20]. It is difficult to see how Tesla will fulfil its commitment on cobalt, when just 6.5% of the world’s production of cobalt currently comes from North America[21].

To fulfil this commitment in the medium-to-long term, I recommend that Tesla takes the supply of cobalt into its own hands. By buying and developing cobalt mines in Canada and China, Tesla can ensure a steady supply of cobalt within seven years (the time it takes to develop a mine[22]) that is produced at both a cost and ethical standard that is acceptable to Tesla’s customers.

This action may seem radical, but it is the only way for Tesla to overcome its issues surrounding cobalt. There is no sign of the cobalt crisis going away; Macquarie Bank forecasts a global deficit growth from 885 tonnes in 2018 to 7,194 tonnes in 2021[23]. If Tesla is serious about its mission to accelerate the world’s transition to sustainable energy, it has to think big, consider how much energy storage it plans to produce in 2025, and take action now to support its growth plans.

But none of that will solve the question hanging over Tesla right now. In the latest filing of its Conflict Minerals Report, Tesla announced that it will follow Apple’s lead[24] in carrying out independent third-party audits of smelters in its supply chain of another critical material for its batteries, 3TG[25]. Will Tesla have any alternative but to extend this practice to include cobalt, to ensure that the supply of this essential mineral does not become a constraint on the production of its batteries next year? If it doesn’t, it had better have another equally drastic plan up its sleeve if it wants to continue accelerating the world’s transition to sustainable energy, without employing child labour to do so.

(800 words)

[1] https://www.tesla.com/about/

[2] Tesla, 2016 Annual Report, The Gigafactory outside of Reno, Nevada, p. 9, http://ir.tesla.com/secfiling.cfm?filingid=1564590-16-13195#TSLA-10K_20151231_HTM_ITEM_1, accessed November 2017

[3] United Nations Framework Convention on Climate Change, Paris Agreement, Article 2, p. 3, http://unfccc.int/files/essential_background/convention/application/pdf/english_paris_agreement.pdf, accessed November 2017

[4] US Energy Information Administration, Levelized Cost and Levelized Avoided Cost of New Generation Resources in the Annual Energy Outlook 2017, Table 1b. Estimated LCOE (simple average of regional values) for new generation resources, for plants entering service in 2022, p. 8, https://www.eia.gov/outlooks/aeo/pdf/electricity_generation.pdf, accessed November 2017

[5] Union of Concerned Scientists, “How Energy Storage Works”, http://www.ucsusa.org/clean-energy/how-energy-storage-works#.Wgy9z7Q-eHo, accessed November 2017

[6] Lazard, Lazard’s Levelized Cost of Storage Analysis – Version 2.0, December 2016, Capital Cost Outlook by Technology, p. 20, https://www.lazard.com/media/438042/lazard-levelized-cost-of-storage-v20.pdf, accessed November 2017

[7] US Energy Department, “Renewable Electricity Production Tax Credit (PTC)”, https://energy.gov/savings/renewable-electricity-production-tax-credit-ptc, accessed November 2017

[8] news.com.au, “Everything you need to know about Tesla’s battery in South Australia”, July 11, 2017, http://www.news.com.au/technology/innovation/inventions/everything-you-need-to-know-about-teslas-battery-in-south-australia/news-story/a989f74cfccb8a1211de83f5becc60ed, accessed November 2017

[9] Financial Times, “Lack of ethical cobalt undermines Tesla debt issue”, August 11, 2017, https://www.ft.com/content/16436eea-7dcd-11e7-9108-edda0bcbc928, accessed November 2017

[10] Ibid

[11] MINING.com, “Elon Musk’s worst nightmare: child labor and cobalt supply”, http://www.mining.com/web/elon-musks-worst-nightmare-child-labor-cobalt-supply/, accessed November 2017

[12] Reuters, “Electric car boom spurs investor scramble for cobalt”, February 14, 2017, http://www.reuters.com/article/us-cobalt-demand-investors/electric-car-boom-spurs-investor-scramble-for-cobalt-idUSKBN15T1VR, accessed November 2017

[13] MINING.com, “Elon Musk’s worst nightmare: child labor and cobalt supply”

[14] Amnesty International, “Is My Phone Powered By Child Labour?”, https://www.amnesty.org/en/latest/campaigns/2016/06/drc-cobalt-child-labour/, accessed November 2017, accessed November 2017

[15] Financial Times, “Electric carmakers on battery alert after funds stockpile cobalt”, February 23, 2017, https://www.ft.com/content/4f88cb60-f8f7-11e6-bd4e-68d53499ed71, accessed November 2017

[16] Energy and Capital, “One Small Company Is Going to Make Elon Musk Regret His Words”, August 17, 2017, https://www.energyandcapital.com/articles/one-small-company-is-going-to-make-elon-musk-regret-his-words/6019, accessed November 2017

[17] Amnesty International, “This Is What We Die For”: Human Rights Abuses in The Democratic Republic of Congo Power the Global Trade in Cobalt, January 2016, Tiers of the Cobalt Supply Chain, p. 55, https://www.amnesty.org/en/documents/afr62/3183/2016/en/, accessed November 2017

[18] Ibid

[19] electrek, “Breakdown of raw materials in Tesla’s batteries and possible bottlenecks”, November 1, 2016, https://electrek.co/2016/11/01/breakdown-raw-materials-tesla-batteries-possible-bottleneck/, accessed November 2017

[20] PR Newswire, “Cobalt Prices to Rocket as Tesla and Apple Scramble for Supplies”, April 25, 2017, https://www.prnewswire.com/news-releases/cobalt-prices-to-rocket-as-tesla-and-apple-scramble-for-supplies-620374383.html, accessed November 2017

[21] MINING.com, “Elon Musk’s worst nightmare: child labor and cobalt supply”

[22] Financial Times, “Lack of ethical cobalt undermines Tesla debt issue”, August 11, 2017, https://www.ft.com/content/16436eea-7dcd-11e7-9108-edda0bcbc928, accessed November 2017

[23] Macquarie Wealth Management, “The 2017 battery metal story might well be cobalt”, February 7, 2017, p. 6, http://www.barraresources.com.au/wp-content/uploads/2017/02/MacquarieCommodities-Cobalt-070217e.pdf, accessed November 2017

[24] Apple, Supplier Responsibility 2017 Progress Report, Responsible Sourcing, p. 23, https://images.apple.com/uk/supplier-responsibility/pdf/GBEN_Apple_Supplier_Responsibility_2017.pdf, accessed November 2017

[25] Tesla Conflict Minerals Report, Description of Due Diligence Performed on the Source and Chain of Custody of those Conflict Minerals, https://www.tesla.com/about/legal, accessed November 2017

[26] Amnesty International, “This is what we die for: Child labour in the DRC cobalt mines”, YouTube, published January 19, 2016, https://www.youtube.com/watch?v=7x4ASxHIrEA

I found this article to be a very interesting read as I had no clue that Telsa is such a larger driver behind the demand for child labor in Democratic Republic of Congo.

In terms of the potential solutions, while I do agree that ultimately, the only long-term solution would be going up chain in terms of owning / controlling clean supply in North America, I believe in the short to median term, there might be other alternatives that Telsa can consider. The rationale for this is evident in the fact that 60% of the current supply is sufficed by Congo and that it would take years to develop new sites in North America. Therefore, it is unlikely that Tesla would be able to completely avoid sourcing from Congo at least in the short to median term.

Therefore, I believe more practical near-term approach might be to work closely with suppliers from Congo to ensure that child labor in minimized. Also to mitigate cost increases from potential price shock, Telsa might wish to consider hedging, effectively buying insurance against potential increases in the price of cobalt. I believe these maneuvers will allow Telsa to navigate its tricky supply chain dynamics in the short term and provide it the time needed to move up the supply chain in the longer term.

Really enjoyed reading Alex!

While I understand that part of the challenge here is that DRC holds so much of the global cobalt supply, I do think we can draw parallels with the textile industry in South / South East Asia given the competitive advantage that these countries have due to lower labor costs and proximity to raw materials. In order to combat child labor, apparel brands pulled two main levers:

– Many brands put pressure on suppliers through regular audits. Since many suppliers weren’t motivated by penalties, brands started offering incentives and higher prices to suppliers that were able to adhere to their standards [1]. While most of the cobalt in the world is produced in the DRC, it does look like the industry in the DRC is quite fragmented. [2] Creating competition within the local cobalt industry may result certain mining companies moving away from the use of child labor. It is important to note, however, that the incentives that Tesla offers will have to be sufficient enough to offset the increased cost of regular labor.

– In order to create long term sustainable change, however, Tesla will have to work with local governments to create regulation around child labor. This will help Tesla gain significant goodwill from the public, in addition to achieving their goal of suppliers without child labor. Researches that studied the Bangladeshi textile industry found that most other levers were short-term in nature and that putting kids in school was the most effective way to transition from child labor.

I believe that Tesla should work with suppliers in the short term, and with local government in the medium term to ensure continuity of child-labor free cobalt.

[1] Bain, Mark, “Researchers have identified a very simple, universal solution to child labor’s vicious cycle of poverty,” https://qz.com/858374/child-labor-is-a-global-epidemic-but-researchers-in-bangladesh-have-one-blueprint-for-a-solution/.

[2] Yager, Thomas, “2013 Minerals Yearbook: Congo,” https://minerals.usgs.gov/minerals/pubs/country/2013/myb3-2013-cg.pdf.