Future of Footwear? Additive Manufacturing at Adidas

Sportswear manufacturer Adidas is incorporating 3D-printing in its new sneaker line

Introduction: Adidas Futurecraft 4D

Until recent years, the concept of additive manufacturing has largely been associated with prototyping and low-volume production. Rapid advances in research and development have moved forward the technology, and as additive manufacturing methods become cheaper and faster, 3D-printed parts are becoming more ingrained in retail and consumer goods.

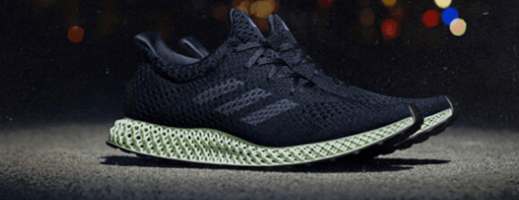

In footwear, Adidas is one such organization at the forefront of this evolution. Last year, Adidas announced the introduction of its Futurecraft 4D shoe[1] – a sneaker that uses a midsole formed with 3D-printed material. The Futurecraft midsole is a lattice structure created from liquid resins hardened by “digital light synthesis” technology[2]. The sneakers are currently priced at $300, placing the shoes as a more premium product among Adidas offerings.

Adidas’s Additive Manufacturing Strategy

For Adidas, a shift towards additive manufacturing translates to reduced production costs throughout the supply chain. In manufacturing, reduced costs come from eliminating expensive steel-molds used in traditional sneaker production. On the distribution side, additive manufacturing allows for a more localized approach to delivery – Adidas currently manufactures most of its shoes in Asia, whereas its Futurecraft 4D line can be produced closer to point of use due to the comparatively lower fixed costs of production for 3D-printing. Bringing production closer to point of use means that Adidas can cut down delivery times and shipping costs for its consumers.

Additive manufacturing also shortens up the production development cycle of Adidas products. Compared to the 15-18 months it takes from ideation to store sales in normal factory production of sneakers, it took just 11 months for the Futurecraft 4D release earlier this year[3]. Product introduction cycles can further be shortened to 2 months as capabilities continue to develop[4]. In a highly diversified market, shorter product lifecycles allow Adidas to maintain lower inventory levels, rapidly iterate, and effectively stay ahead of consumer trends.

In the short term, Adidas plans to scale up its bandwidth to produce Futurecraft 4D sneakers at higher volumes. Demand has vastly outpaced production[5], and the limited release versions of the sneakers have appeared on resale markets at almost $3,000 per pair[6]. To meet demand requirements, Adidas has secured enough 3D-printing capacity to produce one million sneakers per year[3], a drastic increase over the most recent annual production release of 5,000 shoes. In the meantime, Adidas is continuing to offer multiple small-scale product releases each year.

For the long term, Adidas plans to use 3D-printing solutions to generate customized Futurecraft sneakers based on individual physiological and performance needs [4]. The shoe will have a different geometry and lattice structure based on each athlete’s build, foot structure, and use of the shoe. The personalized shoe would then be manufactured at local “micro-factories” to allow for shorter delivery times [7].

Recommendations

With recent investments into manufacturing capacity, Adidas should hold off on introducing Futurecraft shoes to the mass market until due diligence in testing the product is fully completed. As mass customization creates room for error, producing a high-quality product and maintaining credibility is especially essential when competitors like Nike are developing their own 3D-printed offerings [9]. Updates to the software used in the additive manufacturing process can be rolled out without compromising investments on the hardware side. In other words, Adidas can continue building up the capacity to produce while tweaking the design and formula of the lattice structure. Adidas already has an early-mover advantage by building brand awareness through limited releases of the product – the company just needs to make sure to prove out large-scale manufacturing capabilities, especially regarding customization, before a larger release.

Moving forward, Adidas should also consider creating the “upper” (or top) part of the sneakers through additive manufacturing. As the shoe is currently designed with only the midsole part of the shoe being 3D-printed, the product is still somewhat constrained since manufacturing the rest of the shoe occurs via a different production process. Having a consolidated manufacturing platform would allow for more customization and localized production. Customizing the “upper” would allow Adidas to catch up with Nike, who already produces a shoe with a 3D-printed upper portion[8].

Questions

With rivals like Nike developing their own customizable 3D-printed offerings, how will Adidas keep a competitive edge? With lower costs of production, the development of additive manufacturing technology arguably creates a more crowded competitive landscape in footwear. How will established retailers compete with emerging players?

Word Count: 761

[1] “Adidas Futurecraft.” Adidas United States, www.adidas.com/us/futurecraft.

[2] “Adidas Announces Release Of FUTURECRAFT 4D, Officially Ushering In The Future Of Sport Performance Footwear.” Adidas NEWS STREAM, 12 Jan. 2018, news.adidas.com/us/Latest-News/adidas-announces-release-of-futurecraft-4d–officially-ushering-in-the-future-of-sport-performance-f/s/cab3cf86-0f80-4a8d-93c2-e7388f6a908b.

[3] Cheng, Andria. “How Adidas Plans To Bring 3D Printing To The Masses.” Forbes, Forbes Magazine, 23 May 2018, www.forbes.com/sites/andriacheng/2018/05/22/with-adidas-3d-printing-may-finally-see-its-mass-retail-potential/#46fe16904a60.

[4] Petch, Michael. “Adidas and Carbon Announce Futurecraft 4D and Plans for Industrial Scale Mass Customization with 3D Printing.” 3D Printing Industry, 7 Apr. 2017, 3dprintingindustry.com/news/adidas-carbon-announce-futurecraft-4d-plans-industrial-scale-mass-customization-3d-printing-110274/.

[5] Dillet, Romain. “How Adidas and Carbon Are Changing the Sneaker Supply Chain.” TechCrunch, TechCrunch, 7 Sept. 2018, techcrunch.com/2018/09/07/how-adidas-and-carbon-are-changing-the-sneaker-supply-chain/.

[6]Welty, Matt. “The Most Expensive Sneakers of 2017.” Complex, Complex, 14 Dec. 2017, www.complex.com/sneakers/most-expensive-sneakers-2017/adidas-futurecraft-4d.

[7] “Adidas and Carbon Step into New Supply Chain Processes.” Supply & Demand Chain Executive, 10 Sept. 2018, www.sdcexec.com/software-technology/news/21021571/adidas-and-carbon-step-into-new-supply-chain-processes.

[8] Lai, Eric. “Breaking World-Records with Nike’s 3D Printed ‘Flyprint’ Shoes.” 3D Printing Industry, 17 Apr. 2018, 3dprintingindustry.com/news/breaking-world-records-nikes-3d-printed-flyprint-shoes-132265/.

[9] “Nike’s 3D Printed Elite Shoe Preparing for a Wider Release.” 3D Printing Industry, 1 Nov. 2018, 3dprintingindustry.com/news/nikes-3d-printed-elite-shoe-preparing-for-a-wider-release-142527/.

This is a great essay. It’s interesting that you think Adidas should hold off on releasing Futurecraft to the mass market. My inclination would be for them to advertise this shoe as widely as possible in an effort to become known as the pioneer in 3D printed sneakers. This would be accretive to Adidas’ brand, and make Nike look like a laggard in the category. Regardless of their marketing strategy, I agree with you that highly customized 3D printed sneakers will become very common in the future and will revolutionize the way we shop for shoes.

When thinking about how new players may enter the market, I think about how easily they could replicate the process. Some factors that I would consider when examining barriers to entry would include startup and variable costs. For startup costs, I would look at how expensive the printers are, compared to the shipping savings from producing locally. For variable costs, I would look at how much the rubber composite would cost to develop or procure. If this price is too high, 3D printed shoes may remain a premium consumer good.

I am interested whether Adidas could use the 3D printing to customize the shoes to an invidual’s foot. You could come in, have a foot scan, and get a perfect size and width made-to-order with the design of your choice (customized designs for an added fee of course). As mentioned in the article, new players in the market will be easily able to jump in as the cost of printers drops, thereby dropping the fixed costs (which before could only be dealt with economically by scaling up to spread the fixed costs) and shifting most of the costs to variable costs (a great model for newcomers). I think Adidas (and Nike) will have a competitive advantage because of their brand recognition and will become even more fashion companies, rather than innovation companies.

I like how the article shows quantitative and qualitative benefits of the innovative production system both in the short and the long term. It was particularly interesting to see the recommendation of delaying the formal launch of the Futurecraft until the company has confidence that the product actually has the expected quality. In this line, I think that this recommendation should be more or less applicable depending on what the company is looking for with the Futurecraft shoes. Is Adidas mainly aiming to be the first mover with the “3D printed” sneakers? Or is Adidas using the technology mainly to become more efficient in terms of costs and development, production, and distribution times? If the latter is the main objective, I agree with the recommendation of delaying launch and mass production until the due diligence is fully completed, compromising time for quality. If the objective is the former, I think that Adidas should further expand what is currently doing, continuing launching the limited releases of the product in all the markets, heavily investing in quality control for this initial phase (compromising profitability for time and quality), and continue taking advantage of the first move in all its geographies.

I love this post. As I read it, there are two points I would like to comment on:

1. On your point about customising shoes: I found very interesting that they will be able to do this. Even though most of the costs for 3D printing are variable costs, I assume that there are substantial additional costs for designing and developing a new shoe for a specific person (measuring, testing, etc.). Would the costs for this not be too high? What would be the price for such a shoe?

2. On your question about having a competitive edge: I dont think 3D printing will take any competitive edge away from Adidas. For Adidas, as well as for other sports brands, the main competitive edges that they have are design and brand recognition. None of this will change with the introduction of 3D printing. The operational costs might change, but I dont see that as a big differentiating factor.

This article is really interesting – footwear is a space where 3D printing can have huge impact and completely overhaul the current manufacturing process. I tend to agree that Adidas should hold off releasing the shoe until they are sure that there are no errors. I agree with Eric that widely advertising the shoe makes sense, but acknowledge that the risk of errors is too great to release the product until due diligence is performed. Since Nike is also moving in this space, reputational loss would be extremely damaging to market share and association of Adidas with quality going forward.

Adidas needs to maintain a competitive edge through an engaging and far-reaching marketing campaign. The most important thing is that customers see Adidas as being at the forefront of 3D innovation in footwear; Adidas should move quickly to cement its position in this market. As part of the marketing campaign, Adidas could use scientists with expertise in 3D printing and footwear specialists to endorse the shoes, in addition to the traditional approach of having athletes do so. This would ensure that customers associate the design with reliability and excellence, and would help to remove mistrust.

The most important advantage established retailers have over new entrants to this market is strong reputation and brands associated with excellence. Adidas should make use of marketing as discussed above, and endorsement by famous athletes. It should also ensure that the design and functionality of the shoes are perfect before release, to cement a strong brand association in 3D printed shoes. This will ensure Adidas remains relevant as the market becomes more competitive.

Enjoyed reading the article! I agree that additive manufacturing not only provides flexibility in production but can also reduces costs through enabling closer production proximity to demand, lowering fixed costs and shortening product development cycles. Nevertheless, I believe traditional mass production would still be a significant portion of the mix, especially in the geographies where supply and demand are closely consolidated, at least until cost of additive manufacturing can leverage economies of scale. Moreover, Adidas needs to think about addressing certain risks that come with a new way of producing high quality products. Lower entry barriers increasing competition, complexity in choosing the right material used in production, and ensuring comfort and durability are some of the risks I see going forward.

I loved this article. It is so cool to see 3D printing in products used every day. I am not sure if I have come across someone wearing a 3D printed shoe but I will definitely now be on the look out.

I appreciated how the author eloquently elucidated how 3D printing impacts the whole supply chain, not just the manufacturing process (including distribution costs, cost of resources, etc.). Certainly, 3D printing can change the whole cost structure of the industry. As such, is this just a race to the bottom with Nike, New Balance, and others? Will 3D printing drive down costs and thus prices for sneakers, reducing margins for the whole industry? It is interesting to think that such an innovation can actually reduce profitability in the long run as it becomes more commoditized. I like how the author recognized that Adidas needs to figure out how to create a sustainable competitive advantage.

My last thought is: how does a 3D printed shoe perform? Is it comparable to a shoe that is manufactured normally? Ultimately, performance is key and I wonder whether there is a discernible difference (or advantage) to 3D printed shoes.