Don’t Cry Over Sour Milk, Fix It

Chobani's hockeystick growth came to a screeching halt as a result of supply chain mismanagement – then an integrated digital supply chain came to the rescue

Chobani revolutionized the way we think about yogurt, raising our standards from the traditional sugar-laden, watery stuff to thick, creamy, full of protein, and elevating the term “Greek” to be synonymous with high quality. It grew to $1 billion in revenues from 2005 to 2010 in an area historically dominated by two or three big companies for decades (4). Critics could describe this as a blind sprint to growth – aggressively pursuing revenue at the expense of critically looking at its supply chain and distribution, and completely overlooking the need to digitize and adapt to using data to communicate and develop an extended, fast, and agile supply chain process.

Old fashioned supply chains caused Chobani’s major headaches

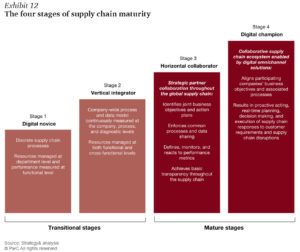

Supply chain digitization needed to have been at the forefront of Chobani management’s concerns, and I argue that a lack of movement towards digitization caused many of Chobani’s problems post-2010. For software products managing each part of the supply chain to communicate would have made production much more cost efficient, and improved quality control – both critical issues that Chobani encountered (3).

- Inefficient procurement in one-off purchasing led to millions of wasted dollars and general unused capacity in an expectation of more aggressive growth than was reality (10)

- Disjointed supply chains interfered with Chobani’s ability to procure and deliver products in increasingly volatile weather conditions (5)

- This came to a head in August 2013 when customers started reporting incidences of mold in containers and resulting illnesses, leaving Chobani facing intense public backlash, and issuing a a recall in September (6)

IT/OT convergence has brought Chobani back on track

Chobani went on to reevaluate and make changes, hiring a new SVP of supply chain and operations, Andreas Sokollek who immediately expressed a commitment to modern distribution (2). Sokollek’s team went on to save $10 million from negotiating better prices for raw materials and reducing waste (10). Critically, he recognized the need to evolve to a connected digital supply chain.

While the old systems were a hybrid model of digital, physical, and entirely siloed discrete pieces, the company has undergone a project for information technology / operational technology convergence (IT / OT) – that is, they have now integrated IT systems that use data-centric computing with OT systems that are used to monitor events, processes, and make adjustments in operations (7). Historically, OT has not been networked technology, and many devices for monitoring have been closed individual systems. To avoid the inefficiencies and quality problems that had stunted its previous hockey stick growth, Chobani focused on:

- Key areas of infrastructure like process automation hardware and programing are now integrated

- Constant online communications to be paramount in daily functionality of the plant, expanding into startup, testing, expansion into new locations, and general support up and down the supply chain

The goals of the IT/OT convergence project were to “increase productivity, reduce downtime, execute faster changeovers, meet and exceed regulatory demands, be dynamic and flexible for growth, maintain product diversity, and support business demands” (7). As a result of this project, Chobani can realize 99% uptime on communications and controls, such that everyone on the line can be aware of the needs of the entire chain.

Innovating and modernizing further is the key to Chobani’s continued relevance and success

Chobani should further address this trend towards digitization by directly responding to the pressure that companies face to bring products to market faster while maintaining quality control. Consumers increasingly want to know where their food ingredients come from, especially with the rise of allergies and demand for organic food (8), and to keep up with the trends that allowed Chobani to rocket to success, it must adapt to future trends, and adapt its manufacturing along with it (9).

- Chobani’s infrastructure must be overhauled to be capable of sharing data in order to be fully transparent and flexible.

- There must be more visibility up and down the supply chain to optimize flexibility and quality control – Chobani needs to understand the timing and quality of raw materials coming in to create the conditions within the factory to minimize waste and avoid contamination. Enterprise resource planning (ERP) can help optimize scheduling on top of existing software, while integration models have the capability to leverage existing software to automate data and tie information together.

- Advanced analytics systems must be implemented in order to fully understand all plant data available, but also externally to understand feedback coming directly from the consumer

- The extreme end of this flexibility is to be able to respond to consumer feedback in real time. The goal of a completely digitized and integrated supply chain is ambitious, to build a chain both resilient and responsive.

Remaining questions about the future of digitization and Chobani:

- How will security in a completely connected plant be affected in the age of hackers and electronic terrorism?

- How large are the downsides to being predictive? Do controls need to be put in place to avoid overindexing on flexibility?

[794 words]

(1) Berttram, Philipp, and Stefan Schrauf. 2017. “Industry 4.0: How Digitization Makes The Supply Chain More Efficient, Agile, And Customer-Focused”. Strategyand.Pwc.Com. https://www.strategyand.pwc.com/reports/industry4.0.

(2) “Chobani Builds On Strong Commitment To Quality And Distribution, Names New SVP Of Supply Chain And Operations”. 2013. Prnewswire.Com. https://www.prnewswire.com/news-releases/chobani-builds-on-strong-commitment-to-quality-and-distribution-names-new-svp-of-supply-chain-and-operations-230980011.html.

(3) “Digitizing The Value Chain”. 2017. Mckinsey & Company. https://www.mckinsey.com/business-functions/operations/our-insights/digitizing-the-value-chain.

(4) Durisin, Megan. 2017. “Chobani CEO: Our Success Has Nothing To Do With Yogurt”. Business Insider. http://www.businessinsider.com/the-success-story-of-chobani-yogurt-2013-5.

(5) Gasparro, Annie. 2015. “At Chobani, Rocky Road From Startup Status”. WSJ. https://www.wsj.com/articles/at-chobani-rocky-road-from-startup-status-1431909152.

(6) Jaslow, Ryan. 2013. “Chobani Recalls Some Yogurt Lots For Mold, Illness Reports”. Cbsnews.Com. https://www.cbsnews.com/news/chobani-recalls-some-yogurt-lots-for-mold-illness-reports/.

(7) “Integrating Process & Business Systems For Manufacturing Chobani Yogurt | ARC Advisory Group”. 2017. Arcweb.Com. https://www.arcweb.com/blog/integrating-process-business-systems-manufacturing-chobani-yogurt.

(8)”PMMI”. 2017. Pmmi.Org. https://www.pmmi.org/gateway?dest=/business-intelligence/webinars/2017-trends-food-processing-webinar.

(9)”Paving A Way To The Digital Plant | Profood World”. 2017. Profoodworld.Com. https://www.profoodworld.com/articles/paving-way-digital-plant.

(10) SCDigest Editorial Staff. 2015. “Greek Yogurt Pioneer Nearly Loses It All Due To Supply Chain Woes”. Scdigest.Com. http://www.scdigest.com/ontarget/15-05-26-2.php?cid=9340.

kaizen, this is such an illuminating piece – thank goodness Chobani got its act together! I love Chobani, but I’ve also never confronted moldy Chobani – ick. Your piece reinforces that supply chain digitization has allowed Chobani to transform from a disjointed mess into a more unified operation with less waste, fewer bottlenecks, and better communication with suppliers, all of which resulted in a more competitive (and less moldy, phew) product. Our supply chain classes notwithstanding, it was still eye-opening for me to learn that at the end of the day, even a yogurt with a winning recipe is only as good as its supply chain is efficient.

Reading about Chobani’s ups and downs, though, I can’t help but wonder if there is an inflection point at which digitizing becomes more effective than old-school/classic supply chain practices, and whether there is an argument to be made for starting out with an old-school model. Chobani seems to have performed exceedingly well from 2005 through 2010, when it hit $1 billion in sales. It seems that digitization wasn’t necessary for that initial stage of rapid growth. It wasn’t until after 2010 that supply chain woes undermined Chobani’s performance. Was there something about the company’s expansion or operations at that point that merited digitization? I wonder if digitization was necessary to expand geographic reach. Or perhaps to manage a tipping point with respect to the number of suppliers Chobani worked with. In sum, reading this piece leaves me wondering if moving to digital sooner rather than later is simply the golden rule, or if there is a scenario where it’s in a company’s best interest to start out with a traditional model, and only make investments in digital once operations hit a certain point. Thanks for a great and thought-provoking piece!

Wow, great piece kaizen! I think you specifically called out a crucial aspect of digital supply chains with respect to system integration. Although many companies have supply chains with digital systems in place, if their are walls in between the systems, any connection point offers the opportunity for a digital break down, and communication to fail. I agree though that relying too heavily on predictive data to drive product mix could be detrimental to their operations as well as their consumer perception. I’m most concerned with where their gathering the inputs for the predictions.

If it’s just based on historical purchasing patterns, the predictions may not accurately describe future behavior. Predictions could be improved if Chobani is using a mix of historical data, along with considering what flavor profiles are selling in tangent consumer markets, such as the popular flavors of coffee or even cake. However, this runs the risk of flavors not translating to yogurt well, leaving Chobani with excess unwanted inventory, or even alienating long time customers who prefer seeing traditional flavors on the shelf. I believe Chobani has to find the right balance of catering to their traditional customers while acting swiftly on more adventurous flavor profiles to stay ahead of competition. However, I believe this balance with be difficult to find with limited shelf space and pressure to reduce inventory throughout their supply chain.

Kaizen, thanks for sharing your research and thoughts on the supply chain issues of my favorite yogurt brand! I really enjoyed learning about the IT infrastructure Chobani put in place in respond to the trend of digitalization. In Food and Beverage industry, food safety and quality is consumers’ primary concerns. I can’t agree more that digitalizing and enforcing transparency along the supply chain serves not only as a operational leverage but also establishes brand reputation that can have a long-term impact.

As Chobani continues its growth, procurement and supplier sourcing will be much more complicated given its larger scale. I love the idea of E-procuring and integrating upstream suppliers and downstream distributers into their supply chain system. Taking a step further, I wonder if it would be a good idea to incorporate just-in-time distribution strategy, as we read in the pasta manufacturer Barilla case. As a dairy product with relatively short shelf-life, managing the time from production to consumers can be particularly important and challenging given Chobani’s customer promise of fresh and good quality yogurt. For example, If distributors choose to hold safety stocks more than necessary, or if there’s some logistics problems that will delay delivery, it can potentially lengthen the time to consumers and put Chobani’s customer promise at risk. With digitalized supply chain management, information visibility and data-sharing will enable JIT distribution to be more accurate and manageable.

Interesting article underscoring why it is important for fast growing consumer businesses to focus on their supply chain once they get to sufficient scale. While management is undoubtedly focused on top-line initiatives at new businesses, it is clear they must also have one eye on the supply chain lest operational issues undo all the good work to achieve exponential revenue growth.

However, while focusing on supply chain is important; my gut reaction is that companies like Chobani should not go overboard on supply chain initiatives such as predictive analytics and flexibility. Yogurt is relatively simple and cost-effective to make and while flexibility in the supply chain is important, it is nowhere near as critical as ensuring the quality of the product – both in terms of taste and hygiene. From a manufacturing perspective, there is minimal variation in the types of products Chobani produces and thus even if demand of one particular flavor spikes, it should be fairly easy to satisfy. Even if Chobani misses out on some revenue, it is likely to be a drop in the ocean given Chobani business model is to sell a high volume of low priced goods. In contrast, another public relations fallout from customers falling ill or from a perceived decline in the quality of the yogurt could have much more significant and longer-term ramifications.

As a former Greek yogurt fan turned Skyr fan, I have a deep appreciation for this product. I didn’t realize the challenges Chobani underwent but had I heard about them my money wouldn’t have been on supply chain issues. The move to digital seems intuitive in this ever connected, digital, competitive world we operate in yet it took Chobani a few years to figure out the solution.

To you your question on the tension between predictive analytics and flexibility, I think there is definitely an optimal solution which will vary depending on the market. For mature saturated markets, predictability becomes key as consumer habits become well known and easier to project and fulfill. In new markets, I don’t believe predictive analytics will have much impact initially as the market is being developed but it will be a tool which can be deployed in the future. Furthermore, once the digital capabilities are in place coming into a new market and deploying predictive analytics shouldn’t be difficult. Therefore, I believe the tension between flexibility and prediction is a small one with the impact of analytics far outweighing any restrictions on flexibility.

Your first question is much harder to answer (hence saving it for last) since many firms across all industries are grappling with this same issue. What gives me hope is new technologies such as Blockchain, can help combat the issue of security due to the transparent nature of its system. Additionally, private industry and government are both investing large amounts of resources and human capital in combating counterterrorism, which will ultimately benefit all organizations (1). Chobani should invest measures in ensuring their information remains secure; however, they should actively partner with other organizations which are dealing with the same issues to combat this problem together (2).

(1) https://www.fbi.gov/news/testimony/keeping-america-secure-in-the-new-age-of-terror

(2) http://www.adweek.com/digital/four-internet-giants-formed-the-global-internet-forum-to-counter-terrorism/#/