DHL: Cracking Logistics with the help of Machine Learning

DHL is using Machine Learning and AI to augment its vast logistics platform.

DHL and applications of Machine Learning in the logistics industry

Innovations born out of machine learning and artificial intelligence have significant implications and uses for logistics companies and supply chain companies. A clear example of this is leading logistics provider, DHL, and it plans to augment its logistics platform through the use of Artificial Intelligence and Machine Learning.

Issues facing the Logistics Industry

Logistics and supply chain management have significant implications for every industry. A large-scale logistics company such as DHL therefore, has, in some form, a hand in every industry possible. Such companies need to be able to forecast and manage spikes and drops in demand for key clients and multiple routes, process, weather and other transport delays and process orders as they come in to reduce wait time.

Logistics companies also face significant potential supplier failures such as unpredicted quality issues, failure to produce adequate product, ect. Due to the fact that logistics companies such as DHL only handle the transport of goods and services, they are usually hamstrung to handling such issues reactively resulting in both financial losses and reputational damage.[1] In addition, there are a number of functions which could benefit from automation. These include short term examples as customer service interactions to longer term plays such as fleet automation.

Steps Taken

DHL recently published a report in partnership with IBM Watson outlining the key applications of Machine Learning in the logistics space.[2] The report included steps to address supply chain issues and augment its current capabilities in the short term and long term. Key amongst these has been the introduction of DHL Supply Watch to the company’s Resilience 360 risk management system.

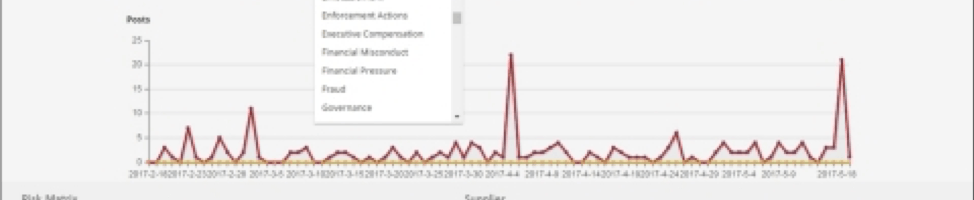

Supply Watch uses a combination of machine learning and natural language processing for early identification of any potential disruptions to DHLs supply chain. The system monitors over “140 different risk categories including financial, environmental and social factors among risks resulting from crime, labor breaches, quality defects and supply chain perils such as shortages, capacity constraints and delays”[3] to help the company proactively inform customers and suppliers of such issues rather than informing customers retroactively after the issue has arisen.

Such enhancements should also allow the company to provide a more personalized experience for its customers through tracking of past orders current activity potentially giving them an edge on competitors. DHL has also suggested it will begin to use chat bots to automate some of the easier customer service engagements.[4] In its joint report, DHL goes so far as to suggest that its predictive models could one day enable them to deliver packages to customers before they have even ordered them.

DHL has taken steps both in the medium and short term to improve its physical fleet management as well. In the short term it is using machine learning to track customer demands improve its route optimization. In the medium term it’s begun to implement automation testing for its ground services. In 2019 it plans to begin testing “truck platooning” or the intelligent caravanning of semi-trucks on a highway- enabling groups of two to five trucks (led by a human driven truck in the front) to follow each other on highways.[5] They are also looking into Autonomous fleets as a more long-term solution. [6]

Further Recommendations

Moving forward, DHL can expect to see machine learning become more a part of its day to day operations from automation of its fleet to the providing risk management information. DHL and other logistics companies in general should then focus their efforts on other parts of the value chain that could benefit from machine learning applications. Two such instances include their suppliers and clearing customs. Even with additional forecasting provided by AI and machine learning, supplier interruptions will remain an issue for any logistics company. By extending its machine learning capabilities on the supply chain management side to its suppliers, DLH may be able to prevent further interruptions from suppliers and develop a competitive advantage beyond its own logistics platform.

In addition, using machine learning to better predict delays in customs clearances will also benefit the company. Customs clearance can often impose significant delays on even the most simple packages. Utilizing machine learning capabilities to predict such delays may allow DHL to further inform customers proactively of wait times, or better help prevent such delays by giving customers the chance to proactively engage customs authorities before a package arrives.

Remaining Questions

Two more important questions regarding DHL’s efforts in machine learning include:

- What besides the areas listed above should DHL seek to improve via machine learning and artificial intelligence?

- How should DHL transparently communicate to customers and suppliers the sources from which it pulls data to improve its operations?

Word Count: 802

Bibliography

Business Wire. “DHL Supply Watch: Machine Learning to Mitigate Supplier Risks.” May 24, 2017. https://www.businesswire.com/news/home/20170524005934/en/DHL-Supply-Watch-Machine-Learning-Mitigate-Supplier/?feedref=JjAwJuNHiystnCoBq_hl-Q-tiwWZwkcswR1UZtV7eGe24xL9TZOyQUMS3J72mJlQ7fxFuNFTHSunhvli30RlBNXya2izy9YOgHlBiZQk2LOzmn6JePCpHPCiYGaEx4DL1Rq8pNwkf3AarimpDzQGuQ==

Business Wire. “Artificial Intelligence to Thrive in Logistics According to DHL and IBM.” April 16, 2018. https://www.businesswire.com/news/home/20180416006323/en/Artificial-Intelligence-Thrive-Logistics-DHL-IBM

Columbus, Louis. “Ten Ways Machine Learning Is Revolutionizing Supply Chain Management”. Forbes, June 11, 2018. https://www.forbes.com/sites/louiscolumbus/2018/06/11/10-ways-machine-learning-is-revolutionizing-supply-chain-management/#36d00c4e3e37

DHL Trend Research. Artificial Intelligence in Logistics. April, 2018. https://www.logistics.dhl/content/dam/dhl/global/core/documents/pdf/glo-artificial-intelligence-in-logistics-trend-report.pdf

Woodie, Alex. How DHL Aims to Remake Logistics with AI. Datanami, April 17, 2018. https://www.datanami.com/2018/04/17/how-dhl-aims-to-remake-logistics-with-ai/

[1] Business Wire. May 2017

[2] Business Wire. April 2018

[3] Business Wire, May 2017

[4] Woodie, Alex, April, 2018

[5] DHL Trend Research. April 2018

[6] Columbus, Louis. June 2018

Fascinating application of ML! Always when I see this applications related to risk monitoring, management and mitigation I ask myself how to meaningfully analyze the data in a way that managers can make decisions. At the same time, there are system design implication to take into account: is data analyzed and then some heuristics are determined to make automated decisions (e.g. delivery truck routing) or are humans analyzing the data and making judgement calls? I think the latter is most effective at this point when ML potential is not fully realized yet

This is a great solution for a company facing very complex and multi-faceted challenges. DHL’s exposure to many different industries and players makes machine learning highly relevant, given its ability to process high volumes of data.

It is interesting that one of the key benefits of Supply Watch is in proactively managing communications to customers and facilitating delivery tracking, rather than in preventing issues from arising. This is an important acknowledgement of the significant negative impact caused by poor expectation management in delivery services. I liked that the article addressed the use of machine learning in customer service, through potential chatbot introduction, and shared DHL’s future ambitious aspirations for machine learning.

I agree that better predictions for suppliers and customs clearance would be helpful. It would be interesting to understand how this capability could be developed, for example whether DHL could work with suppliers to develop capabilities that would benefit both parties for better coordination. For customs coordination, would it be possible to access data to the extent needed for this to work?

In response to the questions in the article, DHL could seek to apply machine learning to support functions to improve their effectiveness. Support functions are often overlooked in process improvement leading to high inefficiencies. DHL should be fully transparent with customers and suppliers about the sources and use of data in its machine learning applications. Since there is a tendency to mistrust machine learning and AI, full transparency helps to build trust and gain cooperation from key stakeholders.

Interesting use cases for ML in logistics! In terms of your suggestion about using ML to better predict delays in customs clearance, I would be asking two follow-up questions to assess the viability of ML as an application before deciding whether or not to pursue it.

1) Given customs clearance involves a government agency as the counterparty (vs. private market actor such as suppliers when analyzing supply interruptions), will there be any confidentiality issues that would inhibit the gathering of a large data set, that includes data for more logistics providers than just DHL. If there isn’t reasonable confidence in the ability to a aggregate a sufficiently large data set, efforts should potentially be directed to use cases where data is more readily accessible.

2) ML relies on the notion that historical patterns can be used to build predictive models of future outcomes. Again, since customs clearance involves government agencies as the counterparties, I wonder if there will be less of a discernible relationship between observable driver variables and clearance time. Private market actors typically have motivations that are more easily unpacked and monitored, but I wonder if the same will be true with government agencies.

I find the shift from big data to small data to further precision data fascinating. Understanding how to best utilize the different types of machine learning that is applicable at different life stages is an important issue to analyze, and something I’m looking forward to learning more about as the technology progresses.

Your questions are spot on! Machine learning and transparency around this new technology are certainly both front of mind for DHL and other logistics companies. Regarding machine learning, an opportunity that stands out to me is DHL’s role in just-in-time-distribution. Could DHL, through machine learning and other artificial intelligence, possibly be the just-in-time-shipping coordinator? All data points to a global supply chain that must adapt to demand for increased customization in physical products. As such, without restructuring the current system, increased variability surely risks toppling the entire network. If DHL were to figure out how to offer just-in-time-distribution for high demand products, reducing the negative side effects of order variability and customization (bull whip effect), this could turn out to be their next major business.

Leaving aside the prophetic capabilities of Watson for a moment, I think there are a few things that DHL needs to seriously consider with this use case. It can attempt to use machine learning all it wants to optimize flow of goods, but this system will be for naught without a centralized asset management system with a form of authentication that is capable of teeing off automated processes every time a good reaches a subsequent destination in the supply chain (e.g. has been authenticated as reaching the “next destination”). Know where I’m headed? – Blockchain. I think DHL is a great use case for moving on from one tech buzz product to another. AI is really only a good use case here for analyzing the overall performance of a supply chain – the core use case of managing the supply chain itself is much better suited to blockchain. Here’s why: an asset (a package) can be moved from one node (location) to another in the blockchain network every time a package is transferred from one location to another. This hand-off will be authenticated by the blockchain. Automated processes (payment, communication, restocking) can be teed off by the blockchain protocol every time an asset moves to a new node without any kind of watsonesque intelligence.

Thank you for sharing an interesting story of how a major logistics player is already leveraging machine learning to forecast and identify transportation delays and capacity constraints before they even occur. The application of machine learning to customs clearance sounds fascinating, particularly as border protection processes are ripe for innovation.

I believe that supply chain management and logistics are two fields where major value can be created from machine learning and where the current applications are only the tip of the iceberg.

With regards to your question, I would recommend DHL apply their machine learning algorithms to forecast and then optimize their mix of ocean freight, air freight and land transportation to achieve cost savings. Moreover, the insights derived from machine learning should improve their strategic supply chain decision-making – for example, where they should set up new distributions centers.

On your last question, I don’t believe DHL needs to or should share the sources of their information with customers or suppliers. That is, unless there is a “need to know” basis in case of e.g. security-related questions.