Dehydrated? So is Nike

Did you know that it can take up to 2,700 litres to produce the cotton needed to make a single t-shirt?1 Considering that the global apparel industry produces more than 150 billion garments in a year (roughly equal to 20 new pieces of clothing for every person on the planet), the apparel industry is both an enormous user and polluter of water2. Apparel manufacturers such as Nike are increasingly feeling the effects of water scarcity and climate change on their operating models.

Climate Change is Slowly Disrupting Nike’s Supply Chain

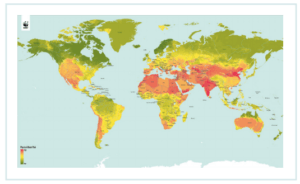

Water scarcity is the top global risk to society over the next ten years according to the World Economic Forum3. The Intergovernmental Panel on Climate Change (IPCC) concluded that increased precipitation intensity and variability due to climate change is projected to increase the risks of flooding and drought in many areas of the world where the textile supply chain operates4. (Exhibit 1) The adverse effects of climate change will constrain water availability for the apparel industry.

Exhibit 1 Map of Water Risk5

Nike utilizes over 700 factories around the world, with many located in regions under high water stress, including China, India, and Thailand6. In 2008, flooding in Thailand temporarily shut down operations at four Nike factories. Extreme weather in regions that produce cotton can disrupt production, creating market volatility in the price of cotton. The company acknowledged concerns that extreme weather caused by climate change can negatively impact its operations going forward, citing it as a financial risk in their 10-K disclosures7.

Minimizing the Dependence on Water

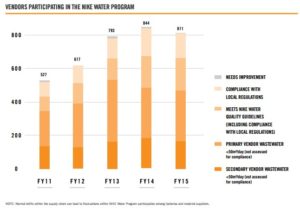

Nike identified the need to innovate with materials and manufacturing processes in order to mitigate the threats posed by extreme weather and global water scarcity and has undertaken several initiatives over the last decade to transform its supply chains. Nike has focused on incorporating lower-impact materials, such as recycled polyester and certified Better Cotton (grown according to the Better Cotton Initiative Standard System) that drive water efficiency8. The company is one of the top buyers of organic cotton, which uses less water than conventional cotton9. Nike is also using more synthetic material that is less dependent on weather conditions. The company developed a ColorDry process that eliminates water from fabric dyeing, which has saved more than 20 million liters of water and minimized wastewater pollution10. Nike also works with contract factories and material vendors to track and report water use and wastewater discharge compliance8 (Exhibit 2). With these initiatives, Nike was able to “reduce water use by 18% per unit in apparel materials and 43% per unit in footwear manufacturing,” far surpassing its goals for 20158.

In 2015, Nike collaborated with researchers at Massachusetts Institute of Technology to study the environmental and social impact of textiles. The goal of the report was “to galvanize the material industry and the chemical industry that supports them into change” and “kickstart a much bigger conversation with the industry [to] send signals to the materials vendors and the chemical companies that do the inventing behind them2.”

Exhibit 2

What Else Can Nike Do?

Included in Nike’s 2020 sustainability goals is the commitment to “innovate and adopt new approaches to reduce water use in [the] supply chain, with a 20% reduction in freshwater use in textile dyeing and finishing (l/kg) per unit of production”8. While Nike has made huge strides towards addressing the negative effects of climate change on their business, efficiency improvements in water usage may not be sufficient to compensate for the growing worldwide demand for water and the negative impacts of extreme weather on water availability. Nike should focus on farther extremes of the value chain, looking at both the harvesting of raw materials and the consumption patterns of end consumers.

Reducing water waste at the raw material stage can have the greatest impact on water conservation, although it is where Nike has the least influence. The World Wildlife Fund estimates that nearly 60% of water used for agriculture (about 396 trillion gallons) is “wasted annually due to leaky irrigation systems and wasteful field application methods11.” Nike should partner with farmers to improve farming techniques so that water is not wasted.

Consumers can also greatly reduce the environmental impacts of their apparel by changing their consumption patterns and the way they care for clothing. It is estimated that 70% of a garment’s lifecycle impact (the sum of environmental impacts caused by the product’s existence) come from washing and drying, and not from the harvesting or manufacturing process12. Nike can focus product innovation on developing apparel that does not require water-intensive laundry care.

One of the biggest obstacles environmentalists face is motivating people to action, and Nike is in a unique position where it can leverage the power of its brand to bring about change at all levels of the value chain.

(797 words)

Sources:

[1] World Wildlife Fund, “The Impact of a Cotton T-Shirt”. January 2013, http://www.worldwildlife.org/stories/the-impact-of-a-cotton-t-shirt, accessed November 2016

[2] Makower, Joel. “Why Nike and MIT See Textiles Material to Climate Change.” GreenBiz, September 2016, https://www.greenbiz.com/article/why-nike-and-mit-see-textiles-material-climate-change, accessed November 2016

[3] Ganter, Carl. “Why World Water Crises are a Top Global Risk.” World Economic Forum. January 2015, https://www.weforum.org/agenda/2015/01/why-world-water-crises-are-a-top-global-risk/, accessed November 2016

[4] Intergovernmental Panel on Climate Change, “Climate Change and Water. IPCC Technical Paper VI”. June 2008, http://www.ipcc.ch/pdf/technical-papers/climate-change-water-en.pdf, accessed November 2016

[5] Sustainable Business Group, “The State of the Apparel Sector 2015 Special Report: Water” 2015, http://glasaaward.org/wp-content/uploads/sites/4/2015/05/GLASA_2015_StateofApparelSector_SpecialReport_Water_150624.pdf, accessed November 2016

[6]Davenport, Coral. “Industry Awakens to Threat of Climate Change”. New York Times. January 2014, http://www.nytimes.com/2014/01/24/science/earth/threat-to-bottom-line-spurs-action-on-climate.html, accessed November 2016

[7] Nike, Inc Form 10-K. May 2015, https://www.sec.gov/Archives/edgar/data/320187/000032018715000113/nke-5312015x10k.htm, accessed November 2016

[8] Nike FY14-15 Sustainable Business Report. http://s3.amazonaws.com/nikeinc/assets/56356/NIKE_FY14-15_Sustainable_Business_Report.pdf, accessed November 2016

[9] GreenBiz. “Nike, Walmart Top US Buyers of Organic Cotton.” June 2010, https://www.greenbiz.com/news/2010/06/01/nike-walmart-top-us-buyers-organic-cotton, accessed November 2016

[10] The Guardian. “Nike ColorDry Adds Water-Free Dyed Fabric to Sustainable Materials Menu.” December 2013, https://www.theguardian.com/sustainable-business/nike-colordry-water-free-sustainable-materials, accessed November 2016

[11] Clancy, Heather. “How to Fix the 10 Worst Wastes of Water.” March 2014, https://www.greenbiz.com/blog/2014/03/19/10-water-system-problems-leaks-nike-microsoft-google, accessed November 2016

[12] Clay, Jason. “Cotton carbon emissions: how the shirt on your back affects climate change.” April 2012, https://www.theguardian.com/sustainable-business/cotton-reduce-environmental-impact-consumer-behaviour, accessed November 2016

To your point I think Nike has enough brand leverage where it can influence both the upstream and downstream in their water usage habits. I agree that working with the farmers at the start of the supply chain is extremely critical. I wonder if in addition to your suggestion of partnering with farmers to improve water techniques, Nike should force down certain standards of improvements to motivate its supplies (i.e. must reduce water usage by 10% if you wish to be our supplier). Of course I think action like this would only be more successful if key apparel players demanded it uniformly, thus reducing the risk that a supplier would just go and supply to someone else. With that said, should Nike take on the leadership role in the apparel industry of coordinating such collaboration? Along the same lines I was curious if Nike shared the color dry process with its competitors. I can see how it could be a competitive cost advantage for them, but I also think they benefit tremendously from a global reducing in water usage and thus might have an incentive to share the process with other apparel providers.

Really well written – tons of well-supported evidence for the state of the industry. I think partnering with farmers is an excellent idea, but worry about the fragmented nature of the industry. Would demanding more from suppliers be a reason for more consolidation of the farming industry? Dealing with fewer vendors from Nike’s side, and standardizing processes, but less competition from the farmers. Additionally, I worry about Nike’s influence on their end consumer. Thats the real global water problem though, isn’t it? People’s water consumption. May be tough for a brand to tell people how to live their lives but likely an equally important battle for them.

Interesting and well-researched post! I agree that Nike is a leader in its sustainability efforts. One powerful aspect of these efforts that I found striking is its advocacy efforts, which I would consider in addition to the ones you’ve laid out above. In 2009, for example, Nike quit its Board position on the Chamber of Commerce in protest of the group’s resistance to climate change legislation. Companies have a lot of power they can use to take a stand, and I was struck by Nike’s willingness to use it in this instance.

http://www.politico.com/story/2009/09/nike-to-quit-chamber-post-027739

Thanks I did not see this post before, but I agree it speaks to Nike’s brand power and its ability to use it to push change.

Nicely written and researched, Alicia! I also wrote on Nike and its sustainability efforts. You propose some very insightful solutions, from (1.) working with farmers to manage resources while harvesting raw materials to (2.) changing the washing requirements for consumers.

Nike was incentivized to work with a Taiwanese facility to come up with the ColorDry technology, since the water savings by this supplier’s process were incorporated into Nike’s sustainability index. With respect to the first point, there must be both an incentive for Nike to change its farmers’ habits, and the farmer must be equipped and compensated for doing so.

With respect to the second point, there must be a coordinated effort for the washing requirements to have an impact; most people in Western countries do loads of laundry and since most of their clothes will require washing, they will still do the same number of loads and use the same amount of water. This raises a bigger question — What will incentivize the apparel industry to come together to reduce the need for water in laundering?

Lastly, I think that MPDHBS2018 raises an interesting question about whether Nike shares its ColorDry technique with its competitors. While I’m not sure if it does or not, Nike does share materials sustainability information through the MAKING app, which allows anyone to see the environmental impact of materials that are widely used in its products. Nike has to strike the right balance between staying ahead of its competitors and sharing sustainability best practices.

http://news.nike.com/news/nike-unveils-new-app-to-help-designers-invent-better

I agree completely with your point about coordinated efforts for washing requirements. I think a few clothing manufacturers (Levi’s comes to mind) are also focusing attention and resources on sustainability initiatives. Perhaps these like-minded companies can form a partnership to encourage more mindful consumption behavior. Since it won’t directly impact any members bottom line (at least in the short term, when water scarcity hasn’t been baked into their costs) these companies would have to be incentivized by the positive PR and customer goodwill that their sustainability efforts will generate. Very much a tragedy of the commons issue!

Great article, Alicia. I think that Nike is making a great progress with less water used in the apparel by constantly innovating and changing their materials. To expand your point regarding need for the broader effort within industry, it would be great to find out, which levers can Nike use to persuade its suppliers to change levels of water used as well. The amount of water used during the raw materials preparation (cotton, for example) could add up significantly to the overall water over-utilization. How difficult it could be to expand the effort and would other players of the supply chain agree? Program that would help to improve water quality standards across all value chain and restrict water usage to minimum levels could have a great potential, but the question is, how much upfront investment would be required by Nike in particular to make it happen?

Very interesting post. I did not realize the extreme extent to which water is being wasted in the raw material stage (60%?!) and agree that something needs to be done in order to better align the suppliers’ incentives with those of the environmentally conscious Nike. While forcing farmers to comply is an option, Nike can also provide incentives to their suppliers in the form of a slight price premium to advocate this change, maintaining its existing base and allowing those suppliers who can be more efficient to do so. I agree that changing consumer behavior will be the biggest driver of water conservation and encourage the company to use its powerful marketing platform in order to educate the consumer of these issues. Whether it is on Nike.com or accompanying youtube videos, the company has the reach to influence many consumers by educating them on the water waste problem and how the company is combatting it with innovative products. As we saw in the Nike football case, the company is in a unique position, given it standing in the industry and continued success in connecting with the end user, to rapidly execute change.

Yes I agree, rather than “forcing” suppliers to become more water efficient (and threatening to go elsewhere if not achieved), I see it as a partnership, where Nike provides resources to help farmers achieve greater efficiency. This could be done via a price premium, or an investment by Nike into the technology that will improve water efficiency (such as better irrigation systems.)