3-D Printing at General Electric – Disrupting Supply Chains and Manufacturing

In a seismic strategic shift, 125-year-old conglomerate General Electric (GE) transformed the future of its supply chain and manufacturing by completing two acquisitions of additive manufacturing (“3-D printing”) companies (Arcam AB and Concept Laser GmbH) for over $1 billion combined in 2016 [1]. 3-D printing is defined as the action or process of making a physical object from a three-dimensional digital model, typically by laying down many thin layers of a material in succession [2]. By 2020, GE expects to utilize 3-D printing as an opportunity to take out $3 billion-$5 billion in costs from its own manufacturing and supply chain operations in addition to selling additive manufacturing machines and services to help optimize the supply chains of other manufacturers [3]. Without going into the nuance of the technology, it is safe to say 3-D printing in its fully realized state will simplify supply chains, reduce product development cycles, cut down on waste, and radically improve product design and performance.

GE operates a highly complex supply chain across its seven industrial operating segments (power, renewable energy, oil and gas, aviation, healthcare, transportation, and energy connections and lighting) [4] encompassing hundreds of thousands of products. Procurement and logistics are increasingly complicated functions at GE which introduce bottlenecks, inefficiencies, and overreliance on external stakeholders. To counteract this burdensome trend, GE has invested in 3-D printing which promises to digitize product development, reduce speed to market, and unlock design breakthroughs. These potential competitive advantages are core to GE’s strategy over the next several decades and are paramount to the company’s well-being moving forward.

In the short term, GE is and has been working to scale its additive manufacturing business via acquisition and internal investment. GE acquired Morris Technologies and Rapid Quality Manufacturing in 2012 [5], Arcam and Concept Laser in 2016, and has invested billions organically in additive technologies for research and development. The short-term benefit comes from designing parts in a simplified manner that can be deployed today, ultimately reducing the cost basis of expensive parts. For example, GE is currently manufacturing an Advanced Turboprop, a jet engine, with 12 3-D printed parts compared with the traditional method of using 855 parts [6]. The Turboprop is expected to be in test planes flown in 2018. This part design reduces complexity, improves performance, and lightens the strain on the global supply chain.

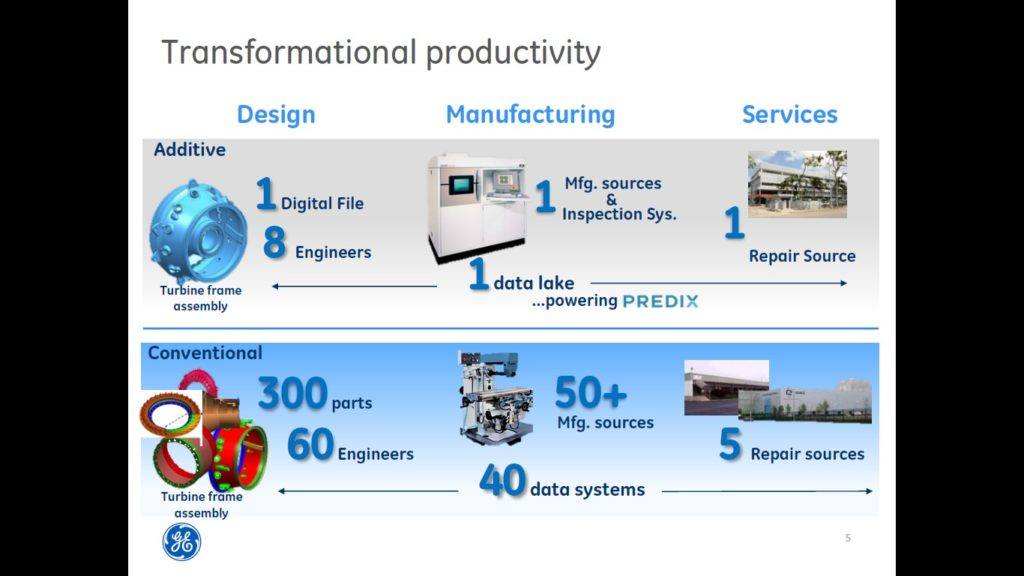

In the long term, GE is exploring how to expand additive applications to other parts of the business as a revenue source and cost optimization tool. By investing in the technology now, GE engineers are developing expertise to transform how GE designs, produces, and transacts in the future. Additive technology requires less manpower and data transfer in addition to fewer machines and company resources. Mastering the technology can lead to competitive advantages in product design in addition to removing costs in the long run. GE expects to realize $10 billion in revenue from additive manufacturing services (i.e. optimizing others’ supply chains) by 2023 (compared with $2 billion in 2015) in addition to several billion dollars in cost savings in modifying its own supply chain and relying on fewer outside suppliers. The following slide [3] demonstrates GE’s potential to reduce supply chain complexity and improve productivity using additive manufacturing.

In addition to its stated ambitions for 3-D printing, GE management should expand the scope of its efforts into healthcare. Currently, GE is focused on industrial applications for its additive technology, such as turbines and jet engines. However, healthcare (15% of GE revenue) [4], is likely the next frontier for 3-D printing. Gartner predicts that by 2019, 10% of people in the developed world will be living with 3-D-printed items on or in their bodies [7] while IndustryARC expects 3-D printing revenue from healthcare to double between 2016 and 2020 [8]. Healthcare requires complex, low volume, customizable solutions which fits perfectly with the 3-D printing technology in development at GE. Educating its suppliers and customers on the benefits of additive technology could serve as a large opportunity to optimize GE’s own supply chain and keep the company top of mind as an innovation expert in the increasingly competitive healthcare space.

Outstanding questions related to GE and additive manufacturing include: which applications are best suited for 3-D printing? How can GE best spread the technology to the developing world? Finally, what is GE’s responsibility to the world as a pioneer in 3-D printing? GE is on the path toward building a world-class, streamlined manufacturing and supply chain operation that, if fully realized, could set the global economy on a path to the next industrial (and perhaps healthcare) revolution.

Word Count: 764 words

[1] “GE Agrees to Purchase Controlling Shares of Arcam AB,” General Electric press release (2016) (https://www.ge.com/additive/press-releases/ge-agrees-purchase-controlling-shares-arcam-ab)

[2] “Definition of 3D printing,” Oxford Dictionary (https://en.oxforddictionaries.com/definition/3d_printing)

[3] “Arcam and SLM Solutions Acquisitions,” General Electric presentation (2016) (https://www.ge.com/sites/default/files/ge_webcast_presentation_009062016_0.pdf)

[4] Securities and Exchange Commission General Electric 2016 10-K Filing (https://www.sec.gov/Archives/edgar/data/40545/000004054517000010/ge10k2016.htm)

[5] “GE Aviation acquires Morris Technologies and Rapid Quality Manufacturing,” GE Aviation press release (2012) (https://www.geaviation.com/press-release/other-news-information/ge-aviation-acquires-morris-technologies-and-rapid-quality)

[6] “Mad Props: A 3D-Printed Airplane Engine Will Run This Year,” General Electric press release (2017) (https://www.ge.com/reports/mad-props-3d-printed-airplane-engine-will-run-year/)

[7] “Gartner Predicts 2016: 3D Printing Disrupts Healthcare and Manufacturing,” Garntner Blog Network (2015) (https://blogs.gartner.com/pete-basiliere/2015/12/02/gartner-predicts-2016-3d-printing-disrupts-healthcare-and-manufacturing/)

[8] “How 3-D Printing Is Changing Health Care,” Wall Street Journal (2017) (https://www.wsj.com/articles/how-3-d-printing-is-changing-health-care-1505268301)

Hi Josh, great article! At GE Appliances we used 3D printing for a variety of applications and were contemplating using it for several others. We used it for prototypes to speed up the process of designing new models but we were unable to utilize it for actual production due to our high volume needs. After we used the prototypes to prove assemblies and fit we would end up sourcing out the production or purchasing tooling to produce the various parts in house.

We were also able to use 3D printing to make a variety of assembly aid tools in house using our 3D printing lab. We could make tools that would precisely fit our needs quickly (such as ergonomic assist tools and poke yoke tools), without having to consult with a contractor to produce tools old fashioned way. Both of the aforementioned applications allow for quick iterations until we got what we wanted, then we could invest in a more permanent solution, if applicable.

One application we were considering using 3D printing for was production of obsolete service parts. After models go obsolete, we still try to carry service parts for several years in case the end customer needs them for any reason (this is actually very profitable for GE Appliances). The problem is, after we no longer produce the part we would have to do one of many options: pay the supplier more money for smaller volume of parts, run overtime to run the parts when we could squeeze it in then store the parts, run a bunch of the parts then find somewhere to store them, etc. If the service forecasts are low enough and especially for larger parts that would take up a lot of room, 3D printing these parts could be an excellent solution.

I really enjoyed this article. 3D printing seems to have faded a bit from the spotlight, as the novelty for the general public has worn off. But your article highlights the true revolutionary nature and value that it provides. I am curious to see the extent to which a durable, precise, high end highly engineered product can be produced in this manner. And also to what extent printers can be miniaturized. An obvious compelling implication would be that instead of transporting a space station to another planet like mars we could transport one explorer and one hand held 3D printer and with that device utilize local materials to build a sustainable habitat.