Project Dreamcatcher: Can Generative Design Accelerate Additive Manufacturing?

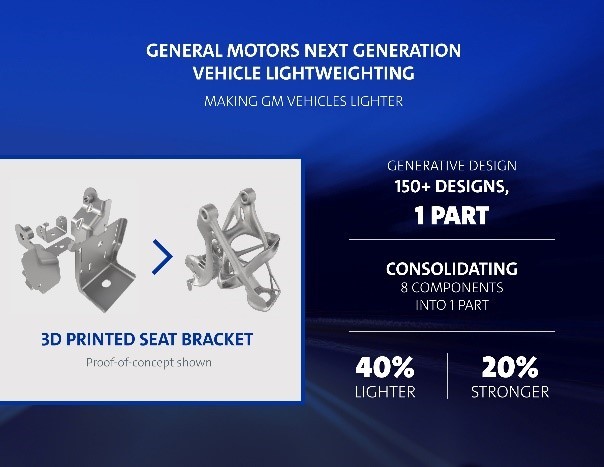

In May 2018, the computer-aided design (CAD) software maker Autodesk announced the alliance with General Motors (GM) to explore the use of generative design and additive manufacturing (AM) in developing future vehicles [1]. Dubbed Project Dreamcatcher, Autodesk’s generative design algorithm utilizes machine learning techniques to generate thousands of design options based on the designer’s input such as functional requirement, material, manufacturing method and other constraints [2]. The outcomes can be optimized for weight or other performance criteria which often result in complex geometry suitable to be manufactured using AM techniques (see Figure 1 for example).

Pathway to Commercialization

Indeed, critics of additive manufacturing have pointed out the lack of suitable software tools for AM [5][6]. Furthermore, engineers are still trained to design according to conventional manufacturing method. A McKinsey report identified this lack of 3D design knowledge as one limitation to current progress of AM [7]. To that end, software makers have attempted to integrate the capability to create AM friendly design to their product offerings.

Project Dreamcatcher is the first one to utilize machine learning techniques to generate design options. This would mean that improvement of the tool is partly dependent on increased usage. Autodesk has released Dreamcatcher features to the latest release of their flagship CAD product – Fusion 360 – which has garnered interest from early adopters in the field. More importantly perhaps is creating proof of concept via alliances with companies such as GM. In addition to partnership in the auto industry, Autodesk has also partnered with Airbus to create lightweight partition for airplane cabin [8]. More than just proof of concept, these early efforts also help build credibility for generative design tools and gain wider traction across industries.

Taking a broader view, much of the promise of 3D printing have been, among others, about increasing efficiency through weight reduction and streamlining supply chain through reduction in number of parts [9]. In the aerospace industry, for instance, GE managed to drastically reduce the number of parts in its propeller from 855 to only 12 while reducing weight by 5% and thereby gaining 20% fuel efficiency [9]. This kind of innovation is also what GM and Airbus are seeking for through the application of generative design. Therefore, Autodesk’s value add in the long run aligns very well with the general direction industries are heading with AM, in that its customer promise aims to allow exploration of novel and efficient designs that go against the current intuition of conventionally trained engineers.

Beyond Software

Autodesk’s long run strategy with Project Dreamcatcher, however, seems to depend almost entirely on the diffusion of AM beyond its current niche usage for prototyping or rare components. Whether AM could eventually fulfil its potential is anyone’s guess at this point. Indeed, naysayers of 3D printing could argue that the Dreamcatcher is nothing but a gimmicky attempt, riding on the additive manufacturing and machine learning hype, to design components that would never make commercial sense to mass produce.

There are at least two ways in which Autodesk could play a more proactive role in ensuring the success of Dreamcatcher in the long run. First, it needs to move from being just a software provider to a trusted advisor for companies in harnessing new technologies. Autodesk could proactively work with companies such as GM to identify opportunities where novel designs generated by Dreamcatcher can be applied to its current and future product, process, and supply chain management. Second, Autodesk needs to build strategic alliance beyond their software users to tap into the wider AM ecosystem. This includes the industry leaders in production of 3D printer and its feedstock such as Desktop Metal. This is crucial because Autodesk needs to ensure its software stays relevant with the progress of AM and could also present opportunities to package its offerings.

The question remains, however, about Autodesk’s readiness to jump beyond a software provider into active influencer in the AM industry. Do they have the right capabilities to provide such advisory services to their clients? Or should they instead hedge their bet by finding alternative usage of Dreamcatcher beyond additive manufacturing, such as in the architecture and urban planning field? (786 words)

References:

- How GM and Autodesk are using generative design for vehicles of the future. Autodesk News. https://adsknews.autodesk.com/news/gm-autodesk-using-generative-design-vehicles-future. Published 2018. Accessed November 13, 2018.

- Project Dreamcatcher | Autodesk Research. Autodeskresearch.com. https://autodeskresearch.com/projects/dreamcatcher. Published 2018. Accessed November 13, 2018.

- Advanced Software Design Technology Leads GM into Next Generation of Vehicle Lightweighting. media.gm.com. https://media.gm.com/media/us/en/gm/news.detail.html/content/Pages/news/us/en/2018/may/0503-lightweighting.html. Published 2018. Accessed November 13, 2018.

- Marshall A. GM’s 3-D Printed Seat Bracket and a Future of Cheaper, Better Cars. WIRED. https://www.wired.com/story/general-motors-auto-industry-3d-printing-additive-manufacturing/. Published 2018. Accessed November 13, 2018.

- The limits of 3D printing. Harvard Business Review Digital Articles (June 23, 2015).

- Roca et al., Getting past the hype about 3-D printing. MIT Sloan Management Review 58, no. 3 (Spring 2017): 57–62.

- Bromberger J, Kelly R. Additive manufacturing: A long-term game changer for manufacturers. McKinsey & Company. https://www.mckinsey.com/business-functions/operations/our-insights/additive-manufacturing-a-long-term-game-changer-for-manufacturers. Published 2018. Accessed November 13, 2018.

- Pioneering bionic 3D printing. Airbus. https://www.airbus.com/newsroom/news/en/2016/03/Pioneering-bionic-3D-printing.html. Published 2018. Accessed November 13, 2018.

- Chain reaction: Why additive manufacturing is about to transform the supply chain. Mechanical Engineering 140, no. 10 (October 2018): 30–35.

Great article, there are many parallels between this and the problems faced in the company that I wrote about. It is interesting to see that beyond just the difficulties in making certain additive manufacturing processes cost efficient at scale, that one of the biggest problems is Additive Design or the lack thereof available in the industry. It seems that a relatively large leap forward is needed in understanding how to design pieces that can fully take advantage of the structures and designs that AM makes possible. I wonder if this is something small start ups will be able to solve or something that will require a decade of different university researchers working in more academic environments to solve.

Interesting article that captures both the macro and micro hurdles that AM must overcome. Given the inertia of engineers that are trained in designing for traditional manufacturing, it seems Autodesk’s best path forward might be to help push AM past a tipping point and shift the industry. Could they make a version of their software open source to allow students and aspiring designers the opportunity to experiment and learn? I’m concerned about the ability for them to grow if the only path to use their software is through working at corporations who can afford the license. Going open source would empower a new generation who would someday work in companies who would push for the purchase of their mainline software.

Autodesk should also consider either growing an internal consulting service or partnering with consulting services to make sure the benefits of their product are known. How many companies would love to do what GE did in your example if they had the expertise? It seems that AM is on the cusp of blowing up, I believe Autodesk should stay positioned in that field so they can ride the wave of the future.

This is an amazing article. In subtle ways, you have addressed challenges of Autodesk as a technology provider in addition to challenges of AM for a technology vendor. Autodesk has been through a similar experience with Building Information Modeling in AEC (architecture, engineering, construction) software by defining the narrative and providing both consulting and software to their clients. It did give them control over the narrative over how software is used but resulted in negative consequence of dependence on software for what is fundamentally a cultural change, and in some cases poor implementation of the software because industry experts were not directly involved in defining the use cases.

I think they still have a chance in additive manufacturing by:

– Growing their AM practice

– Partnering with startups in this space

– Targeting the intersection between construction and manufacturing where companies might benefit from being on interoperable platforms

Great article! When I’ve heard about 3D printing and additive manufacturing in the past it’s usually with the idea that these technologies will follow the same trajectory as say human genome sequencing where the cost exponentially decreased as the technology matured eventually allowing for commercialization. It was definitely interesting to read here that the reality is that nobody really knows how diffusion of the technology will play out. Given that this is the status of the industry on the whole and Autodesk is not alone in facing these challenges, it makes sense to me that they should identify clients where Dreamcatcher can both be of use (i.e. leverage existing technology) and also add signification brand value to Autodesk. The partnership between the 3D printing company Carbon and Adidas comes to mind (https://www.forbes.com/sites/andriacheng/2018/05/22/with-adidas-3d-printing-may-finally-see-its-mass-retail-potential).