Local Motors is crowd sourcing your next car

Local Motors has created an innovative platform which designers and hobbyists interact to bring-to-market low-volume 3D-printed cars at a fraction of the cost of a traditional OEM’s product development process

Overview

Local Motors, founded in 2007 by HBS alum Jay Rogers, aims to bring enthusiasts, innovators, creatives, and professionals closer to the automotive design process through the combination of “co-creation and micro-manufacturing”. By relying on both external and internal talent, the company is redefining the automotive industry’s lengthy, expensive process of product development and manufacturing. Local Motors, as well as companies on the platform, can crowd source vehicle design and leverage 3D printing technology and a network of miniature factories for production. The result is unprecedented access to vehicle/component design talent and low-volume manufacturing

Local Motors had early success with crowd sourcing designs for the first 3D printed car, the Strati. Today, the company continues to redefine the traditional automotive design and build process. They are expanding their micro-factories (currently 3 but they envision 100 within 10 years) to better engage both online and local communities. They are also advancing the pace of 3D printed cars (currently 44 hours to produce the Strati but they intend to lower this to less than 24 hours) while continuing to push regulatory standards on street-legal 3D printed cars.

An early prototype of the Strati, Local Motors’ fully-working 3D-printed car is below. The car takes 44 hours to print, 1 day to mill and 2 days to assemble, making a 5 day build process in total. Cash prize was $5K for the winning submission.

Incentivize participation and manage the crowd

Local Motors has created an innovative platform which designers, companies, and professionals can interact. The majority of users use the platform for personal projects and ideas, leveraging the community for feedback. Buses, taxis, boats, motorcycles, supercars, and autonomous vehicles are just some of the designs uploaded. Several companies have run competitions on the website. One example was the “LITECAR” challenge, which offered $140K in prize money and stringent technical requirements. The competition was run by the Department of Energy’s Advanced Research Projects Agency, in partnership with Local Motors. The goal was to create a safe yet lightweight vehicle by focusing on innovative vehicle materials and structures.

Local Motors runs competitions as well. The company uses the platform for open source design and manufacture and sales of their own vehicles. For example, the Local Motors Rally Fighter was designed by a community member in a 2009 contest. Community members also developed components for the car. The company estimated it spent only $3 million on the car’s development, significantly less than the traditional development cost of a major automaker. The car is now street-legal in all 50 states and for sale on the Local Motor’s website for $99.9K.

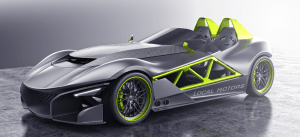

More recently, in 2014, Local Motors ran a design competition to crowd source submissions for an exploratory sports car, dubbed the “Sports Car Platform Design Challenge”. The goal was to select a winning platform from which two different street-legal sports cars could be produced and brought to market within two years. With criteria to scope the effort, designers and hobbyists from all over the world participated and over 200 submissions were received. The criterion were strict and limited the effort to those experienced enough to produce a viable car. Competitors had to take several design aspects into account, including vehicle weight, engine location, drivetrain configuration, total build cost (< $30K), and engine specifications. Cash prizes for the effort were low — only $10K was shared among three winners — significantly less than the billions quoted by traditional OEMs to design a new vehicle platform.

Challenges Ahead

I see several issues with Local Motors moving forward. The community isn’t truly sticky yet and the network effects are weak. There aren’t enough companies/government agencies posting design competitions and the prize money for competitions posted by Local Motors’ remains low. Winners may have a reason to stay for the “street cred” they’ve amassed on the platform, but without a continual pipeline of new competitions, it will be hard to attract new talent and keep certain members active. Competition requirements are also extremely technical and can limit the participation and true creativity of the community.

The company claims to have sold dozens of Rally Fighter cars. However, with low-volume and high fixed costs, they need to focus on vehicles that will sell enough to turn a profit. Their vision of low-volume manufacturing will be difficult given the plan to drastically expand their micro-factories. The company will need to find a way to keep their mills, CNC machines, staff, and other equipment occupied.

Lastly, the buyer also assumes some risk when purchasing through Local Motors. While great for some hobbyists, their current model doesn’t give the average car buyer the piece of mind the make a purchase. The company relies on traditional OEMs to supply the “guts” of the car in order to complete the vehicle and speed regulatory approval. However, this complexity of parts makes warranties/maintenance ostensibly more difficult without going through Local Motors. This will limit their market penetration for a long time to come.

Very informative on a definitely out of the beaten track industry. I agree that it seems like the regulatory hurdle and the weakness of network effects on this market might make it difficult for an independent platform like Local Motors to take off and disrupt the traditional car-making industry. However, the added-value its product brings to the consumer might make Local Motors a great acquisition target for an institutional car manufacturer.

Great post – Local Motors is really interesting. It seems to have created a platform to bring together a community of enthusiasts and it has been harnessed for specific needs (ie the DARPA challenge). I wonder if this is the niche they intend to fill or if the founders truly think there is a possibility of creating a consumer ready vehicle – will regular consumers trust a 3D printed car?

Very interesting post. I read about Local Motors in one of the last HBS Alumni magazines. As a big car fan, this looks definitely something to keep an eye on, although I still have my doubts on the real ability of crowdsourcing as valid tool to come up with better and safer designs compared to what the industry is capable of. Just looking at the numbers, if Porsche or Volvo spend hundreds of millions of dollars in designing a car (and this considers a lot of synergies in terms of all the capabilities and share resources they have built over decades), how is it going to be possible for Local Motors to really create something that matches those standards from the engineering, safety, performance, and all the other aspects that drive cars value? I love the idea, but one thing is to come up with cars that win universities or NGO awards, and something totally different is to win the market where the usual giants play.

I think Local Motors definitely has a spot among other niche limited production car manufacturers. That being said I believe what really drives up automobile R&D costs are the high targets companies must hit in performance, safety, reliability, etc in order to be succesful. Once companies start having to score high marks in all of these categories, the costs to achieve them can become exponential. I would be curious how local motors’ cars stand up against similar competitors. That being said it definitely is a novel idea and it will be interesting to see how this company progresses. Thanks for the post!