BMW – AI Beyond Self-Driving Cars

BWM applies machine learning in the manufacturing process today to get ahead

“Artificial intelligence offers great potential. It helps us maintain our high quality standards and at the same time relieves our people of repetitive tasks.” – Christian Patron, Head of Innovation, Digitalization and Data Analytics at BMW Group Production

Introduction

The race to level 5, fully autonomous driving will undoubtedly change product leadership in the automobile industry forever. In the spotlight, all resources seem to be tied up building the next generation of transportation. Yet in the background, traditional players are utilizing machine learning techniques to improve their manufacturing capabilities, supply-chain optimizations, and foundational R&D. Self-driving cars may change the established hierarchy in the future, but less sexy applications of AI provide return on investment today.

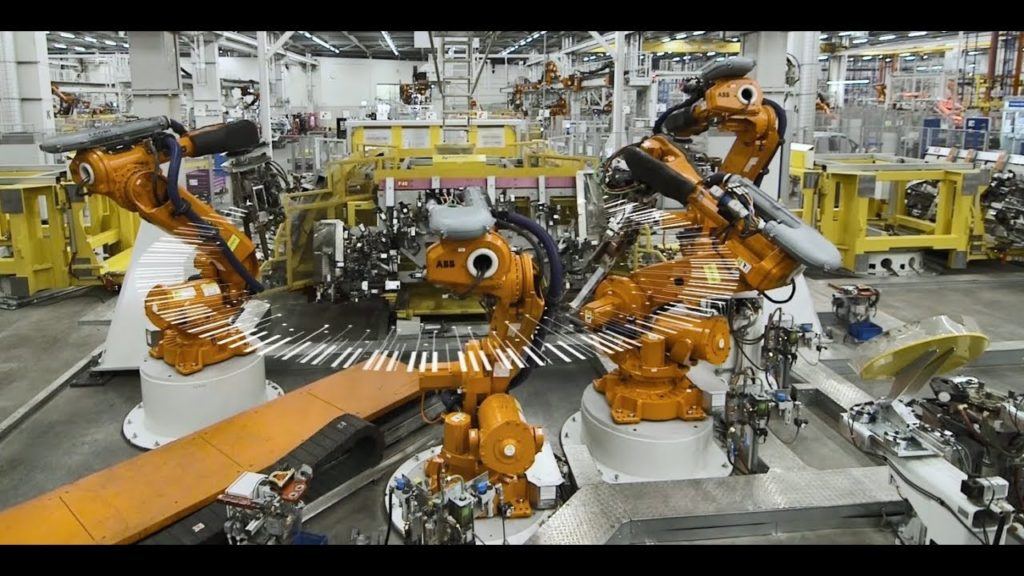

AI along the production line

The German automobile manufacturer BMW has a long history of applying new technologies into their products and production processes. Their Steyer plant is their flagship for advanced manufacturing and a frequent experimentation. Here, artificial intelligence is used to optimize material orders, logistics processes, conveyor belt operations, and quality assurance procedures. Even the plant layout has been optimized by advanced algorithms to let workers and machine more efficient and collaborative. While none of these improvements are as fundamental as autonomous driving, they add up to meaningful incremental cost improvements saving the company millions of dollars.

Image recognition has been a major enabler: Inspections are inherently tedious, repetitive, and stringing on the eyes for any human. Advances in image recognition enables BWM to compare components against their massive database of previously produced output. The comparison allows to check for the correct position at mounting, scratches, and even tiny cracks that might compromise the stability of the part that was just produced. Monotonous check that previously required a human (e.g. checking if the warning triangle has been positioned correctly in the trunk, see if the windshield wiper cap has been installed) can now be accomplished by simple off-the-shelve cameras.

Opportunities and risks in the future

So far, BWM has been building their image recognition capabilities in-house on top of Tensorflow, Google’s widely popular framework for deep neural networks. In December of last year, the company decided to open source future development by uploading their repo on Github, making it accessible to everyone – friend or foe. Christian Patron, Head of Innovation, Digitalization and Data Analytics at BMW Group Production, gives some insight on their reasoning:

“We provide elements of our innovative digital image tagging software, which has proven effective in multiple AI applications; in turn, we receive support in taking our AI software to the next level of development. This allows us to focus more strongly on advancing specific AI applications in production and logistics.“

While this mission is noble, its impact on BMWs competitiveness is questionable. Many foundational developments in data science are open sourced from the get-go. This levels the playing field for most players, commoditizing at least the underlying technology. Differentiation is possible when players are able to adopt the technology and make improvements for their specific use-cases. Most commonly this is done through proprietary datasets, but improvements on the underlying algorithms and workflows offer another avenue of differentiation. By open sourcing, BWM gives other players an ability to catch up by adopting the aforementioned algorithms and workflows. Will they play nice and start contributing their improvements to the code base as well? And will other, third-party developers feel include to contribute? What is their motivation to contribute to a specialty project that’s fitted to the auto industry rather than general purpose AI (e.g. scikit-learn, tensor flow, torch)?

At least for me, that remains to be seen.

Sources

BMW Shares Some of its AI Algorithms Used in Vehicle Production on GitHub (link)

BMW’s Increasing Investment in AI – Insights from an Interview with Sam Huang of BMW iVentures (link)

Fast, efficient, reliable: Artificial intelligence in BMW Group Production (link)

Computer-Assisted Art – the Fascination of AI Design (link)

BMW Is Bullish on AI Technology (link)

Detecting Oversteering in BMW Automobiles with Machine Learning(link)